Rev Up Your Electric Ride: A Complete Guide to Electric Car Battery Charger Schematics

Electric cars are revolutionizing the way we travel, making transportation more sustainable and eco-friendly. However, owning an electric car requires more than just a simple fuel tank refill. In fact, it requires a specialized battery charger to keep the car running smoothly.

But have you ever wondered how an electric car battery charger actually works? In this blog post, we’ll dive deep into the world of electric car charger schematics, exploring the different components that make up this essential piece of technology. From power converters to microcontrollers, we’ll explore the ins and outs of electric car battery charger schematics, providing a comprehensive understanding of how electric cars get charged up and ready to hit the road. So, are you ready to learn about the magic behind charging an electric car battery? Let’s get started!

Introduction

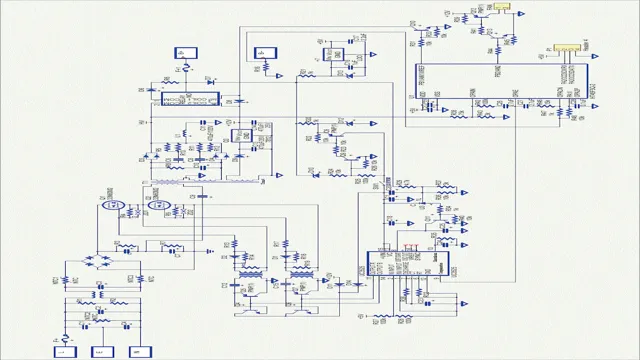

If you’re looking to build an electric car battery charger, you’ll need a schematic to guide you through the process. A schematic is essentially a diagram that lays out all the different components of the charger and how they’re interconnected. You can find many different schematics online, and it’s important to find one that suits your skill level and equipment.

Some schematics may require specialized tools or knowledge of electrical engineering, while others are more accessible for beginners. Regardless of the schematic you choose, it’s crucial to take safety precautions when building your charger. Dealing with high voltage electricity can be dangerous, so be sure to wear protective gear and follow proper procedures.

With the right schematic and attention to safety, you can build a reliable and effective electric car battery charger.

Understanding the Basics of Electric Car Batteries

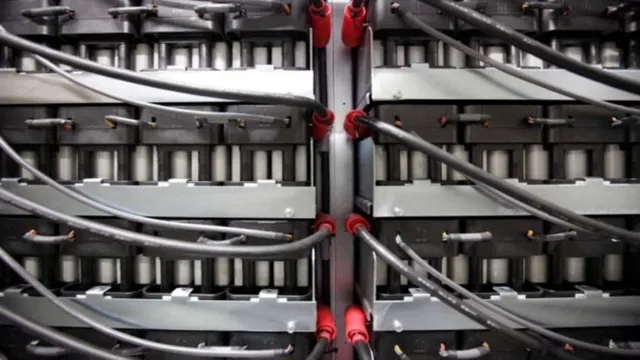

Electric Car Batteries Electric cars are becoming more prevalent in today’s market, with an increasing demand to reduce carbon emissions and promote a sustainable future. Electric cars are not only eco-friendly, but they are also cost-effective and convenient. One critical component of an electric car is the battery which powers the car.

Despite the numerous advances in technology, car batteries remain a primary concern when it comes to electric cars. The battery powers the electric motor, and the amount of power the battery can store and provide will determine how far the car can go on a single charge. Battery technology has come a long way, and newer batteries can last longer and charge faster than their predecessors.

However, there is still much to understand about electric car batteries, including their composition, charging, and maintenance. In this article, we will dive deep into the science behind electric car batteries, how they work, and how it affects the overall performance of the car.

Why Schematics are Important

Schematics are the backbone of any electronic circuit, providing a detailed blueprint of the design and functionality. They are important because they allow engineers and technicians to understand how the circuit operates, troubleshoot problems, and ultimately improve the design. Without schematics, it would be nearly impossible to construct and repair complex electronic systems.

In essence, they are the essential roadmap that guides the building of a circuit from start to finish. The usefulness of schematics cannot be overstated, as they ensure that a circuit works as intended and that all components are connected correctly. As such, schematics are a crucial element of electronic design, and mastering them is essential for anyone who wants to build and repair electronic systems.

The Electric Car Battery Charger Circuitry

The electric car battery charger schematic is a complex system that ensures the efficient charging of an electric car battery. The converter in the charger circuitry processes the AC output from the charging station into the DC voltage required for the battery. The charger circuitry also consists of a control unit that monitors the battery’s temperature, voltage, and current during charging operations.

This enables the charger system to regulate the charging process and prevent any damage to the battery. The charging rate is adjusted by the charger circuitry based on the battery’s state of charge (SoC), ensuring that the battery is charged safely and efficiently. The electric car battery charger schematic is a crucial part of electric cars, and its performance determines the battery’s lifespan and the overall efficiency of the vehicle.

Components of the Charging Circuitry

The electric car battery charger circuitry comprises various components that work together to charge the battery quickly and efficiently. The charging circuitry components include the rectifier, DC/DC converter, battery management system, and the charging port. The rectifier is responsible for converting AC, produced by the power grid, into DC power.

The DC/DC converter then steps down the voltage to match the requirements of the battery pack. The battery management system constantly monitors the state of the battery, such as the temperature and voltage, to ensure optimal charging conditions. Lastly, the charging port acts as a communication interface between the vehicle and the charging station.

Overall, the electric car battery charger circuitry is crucial in making the charging process fast, safe, and reliable, allowing drivers to hit the road with confidence that their electric vehicle has sufficient battery power.

How the Charging Circuitry Works

The electric car battery charger circuitry is a vital component of any electric vehicle. This charging system is responsible for converting alternating current (AC) from the electrical grid to direct current (DC) required by the battery. When an electric car is plugged into a charging station, the charger’s internal circuitry reads the voltage and current limits of the battery and adjusts the power output accordingly.

The charger then converts the AC electricity to DC electricity, which is what the car battery uses to power the vehicle. This charging process should be done safely and efficiently, especially when fast-charging methods are used to minimize the charging time. The charge controller is responsible for ensuring that the battery does not exceed its maximum voltage or current during the charging process, preventing overcharging and damage to the battery.

In this way, the electric car battery charger circuitry plays a crucial role in the successful operation and maintenance of an electric vehicle.

Types of Charging Circuits Available

When it comes to electric car battery chargers, there are several types of circuits available to choose from. One of the most common circuitry options is the on-board charger, which is built directly into the car and allows for convenient and easy charging at electric vehicle charging stations or at home. Off-board chargers, on the other hand, are separate units that can be connected to the car for charging.

These chargers often have higher power capacities and can charge the battery faster than on-board chargers. Additionally, there are also wireless charging options, which use electromagnetic fields to transfer energy to the car battery without the need for cords or cables. This option is still relatively new and not widely available, but may become more popular as technology advances.

Overall, electric car battery charger circuitry has come a long way in recent years, providing more convenient and efficient charging options for drivers.

Designing Your Own Electric Car Battery Charger

If you’re interested in designing your own electric car battery charger, you may be wondering where to start. Fortunately, there are many sources online that provide electric car battery charger schematics and other useful information. One of the first things you’ll need to consider is the voltage and current requirements for your specific electric vehicle.

Once you have this information, you can begin selecting the appropriate components for your charger, including a transformer, rectifier, filter, and voltage regulator. You’ll also need to decide on the type of charging method you want to use, such as constant current or constant voltage. With a little research and patience, you can create a high-quality electric car battery charger that meets your needs and budget.

Just remember to follow best practices for electrical safety and take the time to thoroughly test your charger before using it.

Steps to Designing a Charger Schematic

Designing an electric car battery charger can seem like a daunting task, but with the right steps, it can be done successfully. One of the most critical components of the design process is creating a charger schematic. This involves mapping out the electrical connections and components of the charger circuit, including the AC input, rectifier, DC output, and control circuitry.

A good start is to choose the right components, such as the right rectifier diodes, voltage regulators, and capacitors. It’s also necessary to consider safety features and protection circuitry to ensure that the charger is safe to use. Once you have your schematic, you can move on to the next step of actually building the charger.

With these steps in mind, anyone can design and build their own electric car battery charger.

Essential Considerations for Charger Schematic Design

Designing your own electric car battery charger can be challenging, but it’s an exciting project that can save you a lot of money in the long run. Before starting, there are essential considerations for charger schematic design that you need to bear in mind. First, you need to know the types of electric car batteries to determine the best charging method.

Lithium-ion batteries are the most common, and they require a constant current-constant voltage charging technique. The charging voltage should match the battery manufacturer’s specifications to avoid overcharging, which can damage the battery. Another critical factor to consider is the maximum charging current, as exceeding it can cause overheating and battery damage.

A good charger schematic design should include overcurrent protection to avoid such issues. You also need to think about the charging time, as it can vary depending on the battery capacity and charging rate. You can calculate the charging time using Ohm’s law, which requires you to know the battery’s voltage, capacity, and charging current.

Lastly, safety should be a top priority when designing an electric car battery charger. A good charger should have input overvoltage and polarity protection, output voltage and short-circuit protection, as well as temperature monitoring. Always use high-quality components and follow the schematic design carefully to avoid any accidents.

With these essential considerations in mind, you can design your charger schematic and start charging your electric car battery efficiently.

Conclusion

In conclusion, the electric car battery charger schematic is like the conductor of an orchestra. It orchestrates the flow of energy from the power source to the battery, ensuring that all the notes are played in harmony. With its complex yet efficient design, it keeps our electric cars powered up and on the road.

So, the next time you plug in your electric car, remember to thank the conductor – your trusty charger schematic!”

FAQs

What is an electric car battery charger schematic?

An electric car battery charger schematic is a diagram that shows the components and connections of an electric car battery charging system.

How does an electric car battery charger work?

An electric car battery charger uses an AC power source to convert the power to DC, which is then used to charge the battery. The charger regulates the charging process to ensure the battery is not overcharged.

Can I use any electric car battery charger on my electric car battery?

No, you cannot use any electric car battery charger on your electric car battery. The charger voltage and current must be compatible with your car battery to avoid damaging it.

What is the typical voltage and current of an electric car battery charger?

The typical voltage and current of an electric car battery charger depend on the battery capacity and charge rate. For example, a 50 kW fast charger may provide around 400V and 125A to charge a 120 kWh battery within an hour.