Cracking the Code: Understanding the Electric Car Battery Cost Breakdown

Electric cars are becoming increasingly popular, with a surge in demand for environmentally friendly vehicles in recent years. However, one of the biggest hurdles to wider adoption of electric cars is the cost of the battery. In this blog, we will break down the cost of an electric car battery and explore the factors driving the price.

As we all know, the battery is one of the most crucial components of the car, and it’s what powers the electric motor. But for many, the cost of the battery is a significant barrier to entry. So, how much does an electric car battery cost, and why is it so expensive? Let’s dive in and find out.

Introduction

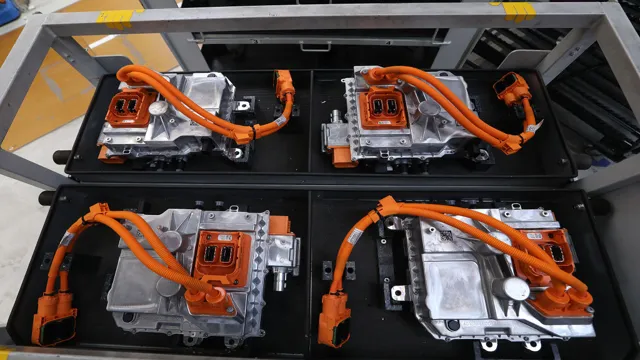

Have you ever wondered what the cost breakdown is for electric car batteries? It’s a question that many people have as the popularity of electric vehicles continues to rise. While the cost of electric car batteries has been steadily decreasing over the years, it’s still one of the most expensive components of an electric car. There are three main components that make up the cost of an electric car battery: the cells, the power electronics, and the cooling system.

The cells are the most expensive part of the battery, accounting for over 70% of the total cost. The power electronics, which manage the flow of electricity to and from the battery, make up around 10% of the cost. Finally, the cooling system, which is necessary to keep the battery from overheating and degrading, accounts for the remaining 20% of the cost.

By breaking down the cost of electric car batteries, we can see where the majority of the expense comes from and how it might be reduced in the future.

Understanding the Battery Cost Breakdown

Battery cost is a significant factor in the adoption of electric vehicles. While EVs are gaining popularity all around, there is still a lot of confusion regarding how the battery cost breakdown works. It’s no secret that the battery pack takes a chunk of the vehicle’s total cost, which often pushes the vehicle’s sticker price beyond the reach of ordinary consumers.

But what exactly makes up the battery cost? A typical EV battery pack is made up of various components, ranging from the cells to the cooling system. Understanding the cost breakdown is crucial to making EVs affordable for a wider audience. In this article, we’ll delve into the nitty-gritty of the battery cost breakdown and try to bring some clarity to this complex subject.

Battery Cost Components

When it comes to the cost of electric vehicle (EV) batteries, there are several key components to consider. First, there’s the cost of the battery cells themselves, which can account for up to 70% of the total battery cost. Additionally, there are other components like battery management systems, thermal management systems, and power electronics that also make up a significant portion of the total cost.

It’s important to note that the cost of these components can vary depending on the size and capacity of the battery, as well as the manufacturer and supplier. Overall, the cost breakdown of an electric car battery can be complex and varies greatly depending on the specifics of the battery being used. However, as technology continues to improve and economies of scale come into play, we can expect the cost of EV batteries to continue to decrease in the future.

Raw Materials

When it comes to the cost of batteries, there are several raw materials to consider. The primary components that contribute to battery costs are the cathode, anode, electrolyte, separator, and casing. The cathode and anode are typically made of materials such as lithium, cobalt, nickel, and manganese.

These materials can be expensive, and their prices can fluctuate based on supply and demand. The electrolyte is usually a combination of solvents and salts, which can also vary in cost depending on the specific formula used. The separator is typically made of plastic or ceramic materials, while the casing is usually made of metal or plastic.

Overall, the cost of battery materials can be a significant factor in the final cost of a battery, and manufacturers must carefully consider the cost-benefit of each material used.

Manufacturing Costs

When it comes to manufacturing batteries, there are several cost components to consider. One of the most significant is the cost of the cell itself. The cell is the component that actually stores the electrical energy that the battery produces.

Cells can vary in their chemistry, size, and power output, all of which affect their cost. Another important cost component is the materials used to manufacture the battery. These can include metals like nickel, cobalt, and lithium, as well as plastics and other materials that make up the housing and other parts of the battery.

Finally, labor costs associated with assembling the battery can also have a significant impact on overall manufacturing costs. By understanding these cost components, battery manufacturers can make strategic decisions on materials, design, and labor in order to optimize their manufacturing processes and ultimately produce cost-effective, high-quality batteries.

Research and Development

Battery cost components play a significant role in the development and adoption of electric vehicles. The cost of battery production accounts for a large part of the overall vehicle cost, making it one of the crucial factors that determine the affordability and popularity of these vehicles. Some of the key components that impact battery costs include the raw materials used in the construction of the battery cells, the manufacturing process, and the cost of research and development.

Raw materials such as cobalt, nickel, and lithium, which are essential for battery production, can be expensive, increasing the overall cost of production. Similarly, the manufacturing process is also a critical factor that affects the cost of batteries. The cost of building factories, equipment, and materials used in the manufacturing process can significantly affect the cost of the final product.

Finally, research and development costs are vital for advancing battery technology and improving efficiencies, but can also contribute to increasing costs. As technology advances, battery components, such as anodes, cathodes, and electrolytes will continue to evolve and improve, leading to more affordable and efficient batteries. Overall, understanding the cost components of batteries is essential to the development of electric vehicles and advancing this technology towards a more sustainable future.

Impact of Battery Cost on Electric Car Price

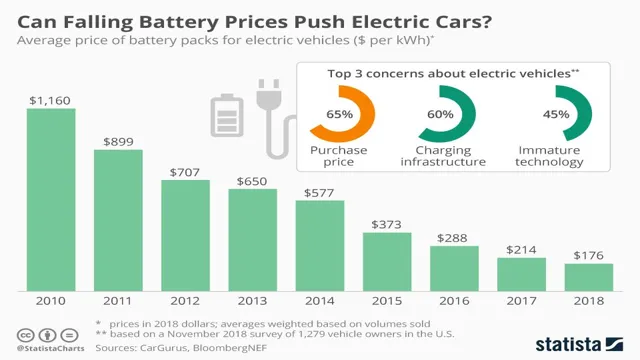

The battery cost breakdown is a significant factor that impacts the price of electric cars. It is well-known that the battery constitutes a substantial proportion of the total cost of an electric car, comprising up to 40% of its manufacturing cost. However, over the past few years, the cost of batteries has been decreasing at a rapid pace, which has also led to a reduction in the overall price of electric cars.

This reduction in battery cost is due to the advancements in technology and an increase in the production scale of batteries. As a result, electric cars are becoming more affordable for customers, leading to an increase in the demand for these vehicles. However, despite the decreasing trend in battery cost, it still remains the most significant factor in determining the total cost of an electric car.

Manufacturers continue to focus on increasing the energy density and reducing manufacturing costs, aiming to make these cars more affordable for the masses and thereby promoting the adoption of electric vehicles. It is safe to say that the battery cost breakdown will continue to play a pivotal role in the electric car market.

Comparison with Gasoline Cars

When considering owning an electric car versus a gasoline car, the impact of battery cost on the electric car price is a major factor to consider. While the upfront cost of an electric car may be higher than that of a gasoline car, the long-term savings in fuel costs can eventually make up for the initial investment. However, the high cost of batteries can still deter potential buyers from choosing an electric car.

As technology continues to improve and battery production becomes more efficient and cost-effective, we may see a decrease in the cost of electric vehicles. It’s important to keep in mind that the price of gasoline cars also fluctuates based on the cost of oil, so the price comparison between electric and gasoline cars may change over time. Ultimately, the decision between electric and gasoline cars will depend on individual priorities and budget.

Battery Cost Reduction Strategies

Electric car battery cost breakdown is a critical aspect that affects the adoption of EVs. The high cost of EV batteries has been one of the barriers to the mass adoption of electric vehicles. However, reducing battery costs is not as easy as it sounds.

There are several strategies that automakers can adopt to reduce the cost of electric car batteries. One way is to improve manufacturing efficiency, reducing energy consumption and raw material usage, enhancing economies of scale, and automating production. Another approach is to develop new and innovative battery chemistries that offer better performance and lower costs.

Recycling mechanisms can also help to reduce costs while conserving natural resources. All these strategies combined can help automakers to achieve cost reduction and make electric cars more affordable for consumers. Ultimately, electric car batteries’ cost reduction is critical to make the switch towards EVs an economically viable option for most people.

Economies of Scale

Economies of Scale One of the most effective strategies to reduce battery costs is through economies of scale. As the demand for electric vehicles and energy storage systems continue to rise, manufacturing companies can produce batteries on a larger scale, leading to a reduction in the cost of production and ultimately, the selling price. This is because with larger quantities, the cost of producing each battery decreases.

Additionally, such production scales also fuel innovations in battery technology. Hence, battery manufacturers can invest more funds towards research and development that can further optimize battery performance. This helps to lower costs while also improving battery life and performance capabilities.

Thus, economies of scale play an important role in reducing battery costs and driving sustainability in electric vehicle and energy storage markets.

Improvements in Technology

Battery cost reduction strategies have become paramount in the era of electric cars and mobile devices. Technology advancements in the manufacturing process have led to a decrease in the cost of batteries, one of the most expensive components of electric vehicles, making them more accessible to everyday consumers. Improvements in the production and design of lithium-ion batteries have led to the use of reduced resources, making the batteries lighter, more energy-dense, and economical to produce.

Battery component recycling has also emerged as one of the potential strategies for reducing costs as recycled materials are cheaper to obtain than extracting new resources. Additionally, the use of artificial intelligence and machine learning in battery management systems has significantly improved battery performance, lifespan, and charging speed, reducing the replacement costs and enhancing user experience. All these strategies will ensure an affordable and sustainable battery solution that could help revolutionize the transportation and energy sector.

Collaboration and Partnerships

When it comes to battery cost reduction strategies, collaboration and partnerships play a crucial role in driving down expenses and bringing about innovation. Manufacturers and suppliers can work together to streamline processes and reduce material waste in production, ultimately leading to lower costs for consumers. Additionally, partnerships with universities or research institutions can provide access to cutting-edge research and development that can lead to breakthroughs in battery technology.

By combining their expertise and resources, companies can achieve cost savings that may not have been possible on their own. Ultimately, these collaborations can result in more affordable and sustainable batteries for everyone.

Conclusion

In summary, breaking down the cost of an electric car battery is like dissecting a magician’s trick; there’s always more than meets the eye. However, one thing is clear: the cost of batteries is rapidly declining, paving the way for a future where electric cars are not just environment-friendly but also cost-effective. So, if you’re still on the fence about switching to an electric car, we say take the plunge – your pocket, and the planet, will thank you in the long run.

“

FAQs

What factors contribute to the cost breakdown of electric car batteries?

The cost breakdown of electric car batteries is influenced by various factors, including raw material costs, technology and manufacturing process, production volume, and government subsidies or incentives.

Why are electric car batteries so expensive compared to conventional gasoline engines?

Electric car batteries are typically more expensive because they require costly raw materials such as lithium, cobalt, and nickel. Additionally, the manufacturing process for batteries is still relatively new and requires expensive equipment.

Will the cost of electric car batteries decrease in the future?

The cost of electric car batteries is expected to decrease as technology advances and production volumes increase. Predictions suggest that the cost could drop to below $100 per kilowatt-hour by 2023, enabling more affordable electric cars.

How do government incentives impact the cost of electric car batteries?

Government incentives such as tax credits and subsidies can reduce the cost of electric car batteries, making electric cars more affordable for consumers. These incentives also drive demand for electric vehicles, which can lead to economies of scale and further cost reductions.