Why the Cost of Electric Car Batteries Can Be Higher Than the Car It Powers

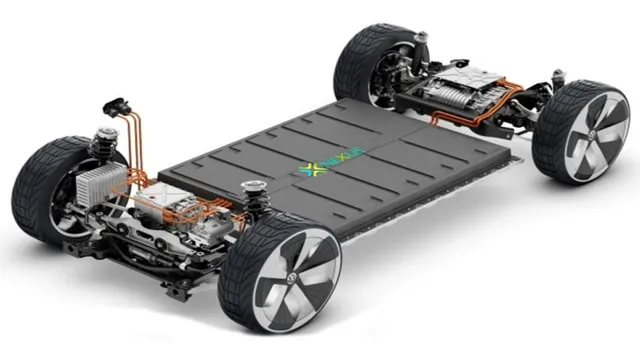

Imagine walking into a dealership to buy an electric vehicle, excited about the prospect of an eco-friendly and cost-effective mode of transportation. But as you browse the price tag, you notice something peculiar – the cost of the battery alone is more than the price of the car. How can this be? Electric car batteries have been hailed as the future of transportation, presenting a cheaper and more sustainable alternative to traditional gasoline vehicles.

However, the hefty price tag of an electric car battery has caused concern and confusion among consumers. In this blog post, we delve into the reasons behind the cost of electric car batteries, and why they seem to overshadow the price of the car.

Supply and Demand

It might surprise you to learn that the cost of an electric car battery can actually exceed the cost of the car itself. This is due to the principle of supply and demand; as the demand for electric cars grows, the demand for batteries grows along with it. Since electric car batteries are still relatively new and not yet produced on a large scale, their production costs are still quite high.

Additionally, the materials used to make these batteries, such as lithium and cobalt, are not cheap. However, this is not to say that electric cars are not worth the investment. In fact, they offer a number of benefits, such as lower operating costs and being better for the environment.

As production scales and the technology becomes more widespread, it’s likely that the cost of electric car batteries will decrease over time. In the meantime, though, it’s important to consider the long-term cost savings of owning an electric car rather than just the upfront cost.

Battery Technology is New and Expensive

When it comes to battery technology, it’s often assumed that the main reason for its high cost is due to the technology being relatively new. While this is partially true, the real culprit is supply and demand. As the market for electric vehicles continues to grow, the demand for batteries also increases, leading to a shortage of materials used in their production.

This shortage drives up the cost of materials and subsequently the cost of batteries. Additionally, the production of batteries requires a large amount of resources and energy, further contributing to their expense. However, as more research and development is done in the field, we can expect the cost to decrease over time as the supply chain becomes more efficient.

Just like any other technology, as it becomes more widely adopted and produced at a larger scale, the cost will inevitably decrease, making it more accessible to the average consumer. It’s important to remember that advancements require investment, and the initial cost of battery technology is a necessary step towards a more sustainable future.

Lack of Infrastructure to Produce Batteries at a Lower Cost

When it comes to the production of batteries, the lack of infrastructure can result in higher costs, making it less accessible for the general population. The supply and demand for batteries have steadily increased but the infrastructure to meet the demand has not kept up. This has led to a higher cost of production for batteries, which then trickles down to the consumer.

However, the good news is that more companies are investing in the infrastructure needed to produce batteries at a lower cost. This will not only make batteries more affordable for everyday people but it will also make them more environmentally friendly as well. It’s important to keep in mind that the lack of infrastructure isn’t just limited to batteries.

Many industries are struggling to keep up with the demand of the market and it’s up to companies and governments to come together and invest in the needed infrastructure to meet the supply and demand.

Cost of Raw Materials

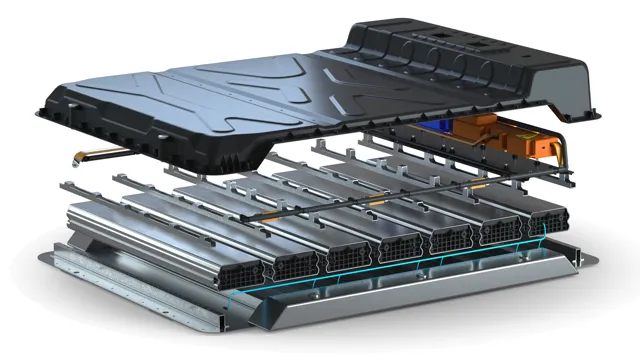

Electric car batteries cost more than the cars themselves and one of the reasons behind it is the cost of raw materials. The majority of electric vehicle (EV) batteries are made using lithium-ion technology which requires several rare and expensive metals, including cobalt, nickel, and lithium. These materials are known for their high energy density and durability, making them the ideal choice for long-lasting EV batteries.

However, the production of these materials involves significant environmental challenges and labor practices. The volatility of raw materials prices also plays a role in the final cost of an EV battery. As the demand for EV batteries continues to rise, so too do the prices of raw materials.

The cost of EV batteries is expected to drop as the technology advances and economies of scale occur, but for now, the cost of raw materials remains a significant obstacle to widespread EV adoption.

High Cost of Lithium-Ion Batteries

The high cost of lithium-ion batteries is a major concern for many industries that rely on these power sources, such as the automotive and electronics industries. One of the key factors driving up the cost of these batteries is the cost of their raw materials. The primary materials used in lithium-ion batteries are lithium and cobalt, and both of these elements come with a hefty price tag.

Lithium is a relatively rare metal that requires extensive mining and processing, while cobalt is typically sourced from regions with unstable political climates, leading to supply chain disruptions and price volatility. Additionally, there are concerns about ethical and environmental issues surrounding the mining of these materials. All of these factors contribute to the high cost of lithium-ion batteries, which limits their widespread adoption and hinders the growth of industries that depend on them.

Finding ways to lower the cost of these raw materials or developing alternative battery technologies could be critical to the future sustainability of these industries.

Unpredictable and Volatile Market for Raw Materials

The cost of raw materials can rise and fall dramatically due to the unpredictable and volatile market conditions. Companies that rely on raw materials for their production process must constantly monitor the prices and availability of these materials to remain competitive. The cost of raw materials can be affected by a variety of factors, including changes in global supply and demand, natural disasters, political instability, and currency exchange rates.

For example, a drought in a major wheat-growing region can cause the price of wheat to rise, while an increase in the value of the US dollar can make raw materials priced in other currencies more expensive. This unpredictability can make it difficult for companies to plan their budgets and maintain profitability. In some cases, companies may need to find alternative sources for their raw materials or adjust their pricing to account for the fluctuations in costs.

Overall, the volatility of the raw materials market requires companies to be agile and adaptable in order to thrive in a constantly changing economic landscape.

Expensive Manufacturing Process

One of the biggest culprits of expensive manufacturing processes is the cost of raw materials. The price of raw materials can vary greatly, depending on the type of material, the quality, the location, and the demand for it. During the manufacturing process, these materials have to be transformed, shaped, and molded into the finished product, which can add significant expenses to the production.

Moreover, some raw materials are scarce and hard to obtain, which increases their costs even more. For instance, rare metals like gold, platinum, and palladium are often used in electronics and jewelry, but due to their rarity, they have a high price point. Similarly, some types of wood, leather, and textiles used in furniture or fashion can be costly because of their premium quality.

Therefore, manufacturers need to be strategic in sourcing their raw materials, exploring alternative materials, and negotiating prices with suppliers to minimize their expenses without sacrificing the quality of the final product.

Battery Life and Warranty

Electric car battery cost more than car, which is why it is important to understand its lifespan and warranty. The battery life of an electric car can vary depending on factors such as usage and weather conditions. On average, an electric car battery can last anywhere from 8 to 10 years or 100,000 to 200,000 miles.

However, after this period, the battery will begin to degrade and lose its overall capacity. This issue is a significant concern among electric car buyers as it can result in a costly replacement. Replacing an electric car battery can cost as much as $5,500 to $15,000.

Fortunately, most electric car manufacturers offer a warranty on their batteries, which can cover any defects or problems for a specified period. Typically, the battery warranty will cover for a minimum of 8 years or 100,000 miles, whichever comes first. Therefore, it is important to review the warranty details when purchasing an electric car.

A strong warranty ensures that you are protected against significant expenses should the battery malfunction or fail to work. Overall, electric car battery cost more than car, but with proper maintenance and adherence to warranty guidelines, electric car owners can avoid costly battery replacement expenses. By understanding the lifespan and warranty details of the electric car battery, buyers can make informed decisions, and electric cars become more viable and affordable transportation options.

Longer Battery Life Comes with a Higher Price Tag

When it comes to smartphone batteries, longer battery life typically comes at a higher price. Many high-end models boast impressive battery life, but they often have a price tag to match. However, it’s not just the cost of the phone that can impact the battery life.

The type of warranty that comes with the phone can also play a role. Some warranties offer extended coverage for battery life, which can provide peace of mind and potentially save money in the long run. It’s important to consider both the upfront cost and the long-term investment when choosing a phone with optimal battery life.

While it may be tempting to opt for a cheaper model, investing in a phone with a longer battery life can pay off in the long run.

Warranty and Maintenance Costs are Higher for Electric Car Batteries

When it comes to electric cars, there’s no denying that the battery is a crucial component. Unfortunately, battery life doesn’t last forever, and that can mean costly maintenance expenses for electric car owners. One key factor to consider is the battery’s warranty, which can range from as little as 3 years to as much as 8 years.

However, once the warranty expires, the owner is typically responsible for any maintenance and replacement costs. While battery technology is constantly improving, the reality is that battery replacements can still be expensive, often costing thousands of dollars. As such, it’s important for electric car owners to carefully consider the battery warranty and factor in potential maintenance costs when making a purchase decision.

The Future of Electric Car Batteries

Electric car batteries have been a talking point for years now, primarily because of their high cost in comparison to the car itself. However, with advancements in technology, the future of electric car batteries seems bright. Lithium-ion batteries, which are currently the most popular type used in electric cars, have already seen a significant decrease in cost over recent years.

This trend is expected to continue, with predictions suggesting that the cost of electric car batteries will continue to drop in the coming years. This is due to increased production, as well as improvements in manufacturing techniques, which will make the process of producing these batteries more efficient. With this decrease in cost, it is expected that more people will be able to afford electric cars, leading to a reduction in harmful emissions and a greener future.

Research and Development Driving Costs Down

As the demand for electric vehicles continues to grow, research and development initiatives are driving down the costs of electric car batteries. The future of electric car batteries looks promising, as new technologies emerge that aim to make them smaller, lighter, and more efficient. Improvements in battery chemistry and the use of new materials, such as solid-state batteries, are also helping to improve the performance of electric car batteries.

As a result, electric cars can travel longer distances on a single charge, making them more practical and attractive to consumers. With advancements in battery technology, we can expect the electric car market to continue to grow and become more affordable for the average consumer.

Increased Demand Will Lead to Lower Costs

As electric cars continue to gain popularity, it’s exciting to see how the future of electric car batteries will evolve. One of the most promising developments is that the increased demand for electric car batteries will lead to lower costs. As more and more people opt for electric vehicles, the volume of battery production will increase, which will in turn drive down costs.

This shift will not only make electric cars more affordable for consumers but also more competitive in the automotive market. It’s similar to the way that smartphones and flat-screen TVs became more affordable as consumer demand grew. With the advancements in battery technology, it’s likely that the cost to produce them will decrease even further, making electric cars an even more attractive option for drivers.

The future of electric car batteries is bright, and we can’t wait to see what other innovations will come in the years ahead.

Improved Technology Will Lower Manufacturing and Raw Material Costs

Improved technology in the manufacturing of electric car batteries will significantly reduce costs. The production of batteries for electric cars requires raw materials such as lithium, cobalt, and nickel, which have been the subject of price hikes due to high demand for the materials. However, with advancements in technology, manufacturers will be able to produce batteries that require fewer raw materials, thereby reducing the overall production costs.

This will translate into savings for consumers, making it easier for more people to afford electric vehicles. Additionally, improved technology will increase the efficiency of the charging process, as well as increase the range of electric vehicles. As a result, more people will be motivated to switch to electric cars, thereby reducing carbon emissions and helping to protect the environment.

The future of electric car batteries is bright, and it’s going to revolutionize the automotive industry – making electric vehicles more accessible to all.

Conclusion

In the world of electric cars, the battery is the heart and soul of the vehicle. Unfortunately, just like in matters of the heart, the cost of keeping it ticking can be quite expensive. While it may seem counterintuitive that the battery can cost more than the car itself, it’s a testament to the incredible importance and complexity of the technology involved.

But never fear, with more advancements in battery technology being made every day, we can all hope for a future where electric cars are not only more affordable, but also more sustainable and accessible. So let’s all plug in, charge up, and drive towards a brighter and electrifying tomorrow!”

FAQs

Why do electric car batteries cost more than traditional car batteries?

Electric car batteries cost more because they require more advanced technology to store energy and power a vehicle compared to traditional car batteries.

Is it true that electric car batteries need to be replaced more frequently than traditional car batteries?

No, electric car batteries typically last longer than traditional car batteries and do not require replacement as often.

What factors affect the cost of an electric car battery?

The cost of an electric car battery can be influenced by the size of the battery, the type of battery chemistry, and the demand for electric cars.

Are there any government incentives for purchasing electric cars that could help offset the high cost of batteries?

Yes, many governments offer incentives such as tax rebates or credits for purchasing electric cars to help offset the higher cost of the battery.