The Shocking Truth Behind Why Electric Car Batteries are So Expensive: Is it Worth the Investment?

Electric cars are becoming more and more popular with environmentally conscious drivers, but one factor that may be holding some people back from making the switch is the cost of the vehicle’s batteries. In fact, electric car batteries can account for up to half of the vehicle’s overall cost, which may seem daunting for those who are used to paying a few hundred dollars for a regular car battery. So why are electric car batteries so expensive? In this blog post, we’ll dive into the reasons behind the hefty price tag and explain what factors contribute to the high cost.

Whether you’re considering making the switch to an electric car or are simply curious about the technology, keep reading to find out why electric car batteries are so pricey.

Cost of Materials

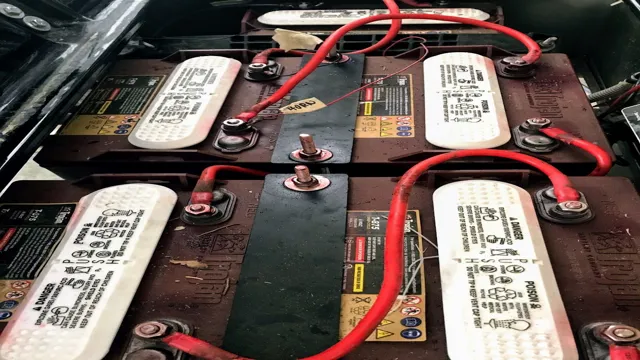

Electric car batteries are notoriously expensive, and for good reason. The cost of materials that go into these batteries is significant, driving up the overall cost of the vehicle. One of the main materials used in electric car batteries is lithium, which is a rare and valuable element.

On top of that, other materials such as cobalt and nickel are also used, both of which are in high demand and can be difficult and expensive to obtain. The cost of these materials can fluctuate and can be impacted by geopolitical events and market conditions. Additionally, the process of manufacturing these batteries is complex and requires specialized knowledge and equipment, further driving up the costs.

However, as technology advances and demand for electric vehicles grows, it’s possible that the cost of these materials and batteries may decrease in the future.

Rare Earth Metals and Lithium

The cost of materials is a significant factor when it comes to the production of rare earth metals and lithium. The demand for these critical components has consistently increased over the years as technologies such as electric vehicles and renewable energy systems continue to gain popularity. However, the cost of extraction, processing, and refining of these materials is relatively high due to their scarcity and complex mining process.

Additionally, geopolitical issues may arise as many of the locations where these materials are sourced are politically unstable or controlled by a single entity. Despite these challenges, companies and governments worldwide are investing more in the research and development of alternative sources and recycling methods to minimize the cost and reliance on primary sources of these materials. As a result, the cost of these critical components is expected to become less prohibitive in the future, making them more accessible and affordable for the general public.

Research and Development

The high cost of electric car batteries is a major concern for many consumers. While electric cars offer a cleaner alternative to traditional gas-powered vehicles, the price tag can be a deterrent for some. The reason for the high cost is due to the research and development required to create these batteries.

Electric car batteries are complex and require advanced materials, technology, and manufacturing processes. This makes them more expensive than traditional car batteries. However, many automakers are investing in research and development to bring down the cost of electric car batteries.

As more and more people switch to electric cars, the demand for these batteries will increase, helping to bring down the cost. In the meantime, government incentives and rebates often make electric cars more affordable for consumers, making them a great long-term investment for those looking to reduce their carbon footprint. Overall, while the initial cost of electric car batteries may be expensive, the long-term benefits and the potential for lower costs in the future make them a smart choice for environmentally conscious consumers.

New and Evolving Technology

In today’s fast-paced world, research and development play a critical role in advancing new and evolving technologies. The continuous advancement of new technologies across all industries requires companies to invest heavily in research and development to remain competitive. This research is a necessary process that allows companies to stay on the cutting edge, and helps enhance the user experience, accessibility and the functionality of new technology.

Areas of research and development encompass, but are not limited to, health care, biotechnology, renewable energy, and artificial intelligence. Every year, companies invest a significant portion of their budget into research and development to tap into emerging opportunities such as developing new products, modifying existing ones and discovering new markets. These investments allow companies to improve the performance and value of their products and services for their consumers.

The world is rapidly evolving, and it’s essential for businesses to keep up with the technological advancements in order to meet customer demands, boost productivity, and economic growth. The key to this evolution is continuous research and development.

Reliability and Safety Standards

As technology advances, the need for reliable and safe products becomes more important. This is especially true in industries such as transportation and medicine. To meet these standards, companies invest heavily in research and development.

They conduct extensive experiments, simulations, and data analysis to ensure that their products are not only functional but also safe to use. They also conduct thorough testing to detect any potential malfunctions or safety hazards. These efforts help guarantee that the products meet the necessary reliability and safety standards.

For example, in the automotive industry, manufacturers conduct rigorous crash tests to determine how their vehicles perform under different scenarios. In the medical field, researchers test new equipment on simulated patients to ensure that they work properly. These measures help deliver products that not only work as intended but also keep people safe.

Overall, companies must invest in thorough research and development to comply with reliability and safety standards. It is the only way to ensure that their products are of the highest quality and safe to use for consumers.

Manufacturing and Production

Electric car batteries are often considered expensive due to the high cost of raw materials and manufacturing processes. Factors such as the growing demand for electric vehicles and the limited supply of materials needed for battery production elevate the cost of production, which is passed on to the consumer. Additionally, investments in research and development are required to improve battery technology and increase its efficiency, which in turn drives up the cost of electric car batteries.

However, experts predict that as battery technology continues to evolve and become more widespread, economies of scale will lead to more affordable prices. As such, the cost of electric car batteries is expected to decrease, making electric vehicles even more accessible and cost-effective for consumers.

Specialized Assembly Processes

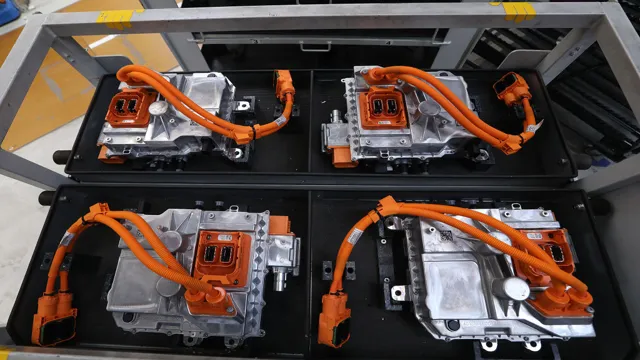

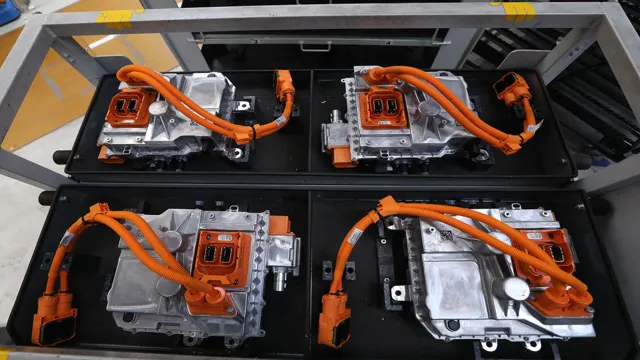

Specialized assembly processes are an essential component of manufacturing and production. These processes involve the use of advanced machinery and expert skills to create complex, high-quality products. The assembly process is critical to ensuring that the final product meets the exacting standards of the customer.

A specialized assembly process can be used to create products like medical devices, automotive components, and aerospace equipment. For example, aerospace parts may require specialized processes like precision welding, riveting, or bonding. These sensitive assembly processes require specialized knowledge and training to ensure the product is safe and reliable.

The use of automation in specialized assembly processes is becoming increasingly common, allowing for faster production and improved efficiency. Ultimately, the use of specialized assembly processes results in consistent, high-quality products that meet customer requirements.

Small Scale Production

Small Scale Production Small scale production is an essential part of any manufacturing or production process. This type of production involves the creation of products or services on a smaller scale, usually in smaller quantities. While larger-scale production can often be more efficient, small scale production allows for more customization and attention to detail, making it a valuable option for certain types of products.

Small scale production also has the benefit of being more flexible, allowing for quicker adjustments and changes to the manufacturing process. However, small scale production can also have its challenges in terms of costs and capacity. It can often be more expensive to produce products on a smaller scale, and there may be limitations in terms of resources and production capabilities.

Despite these challenges, small scale production can be an effective way to create high-quality, unique products that meet the specific needs of customers.

Government Regulations

Electric car battery expenses are one of the major reasons why consumers are still hesitant to switch from their conventional gas-powered cars to electric vehicles. They are much more expensive to produce and replace, contributing to the higher overall cost of an electric vehicle. This is partially due to government regulations that mandate strict safety standards for electric car batteries, which require expensive testing and certification processes to ensure the batteries are capable of withstanding crashes and other collisions.

These regulations have also resulted in limited competition in the market, as smaller businesses find it difficult to keep up with the required testing costs. As a result, electric car batteries continue to remain a significant expense, despite their potential long-term cost savings in fuel and maintenance. However, advancements in battery technology and potential changes in regulations may eventually make electric car batteries more affordable for consumers.

Environmental Concerns

When it comes to environmental concerns, government regulation is essential. Without proper regulations, industries may prioritize profit over eco-friendliness, leading to adverse effects on our planet and natural resources. Governments set standards that industries must follow to minimize their environmental impact while maximizing their profits.

These standards may involve measures such as reducing emissions or utilizing renewable energy sources. Moreover, government regulations can motivate companies to adopt green technologies and practices by providing incentives or penalties. While some may argue that regulations increase the costs to businesses, implementing eco-friendly measures ultimately brings long-term benefits to both the environment and the economy.

Ultimately, it is crucial for governments to establish effective regulations to prevent environmental degradation and promote a sustainable future.

Safety Regulations and Testing

Government regulations play a vital role in ensuring the safety of products we use every day. The government sets standards for testing and certification of various products such as electronics, toys, kitchen appliances, and even vehicles. These regulations mandate that companies must conduct particular safety tests before releasing a product into the market.

For instance, car manufacturers must meet specific safety standards to obtain certification from the National Highway Traffic Safety Administration (NHTSA). Similarly, the Consumer Product Safety Commission (CPSC) regulates safety standards for consumer products sold in the USA. Companies must comply with these regulations to prevent injuries or damages, and failure to adhere to these standards could result in serious legal consequences.

Ultimately, government regulations are essential to ensuring the safety and well-being of consumers.

Conclusion

Well, it seems that the high cost of electric car batteries might just be the price we have to pay for a cleaner and more sustainable future. But let’s be honest, when it comes to saving the planet and cutting down on emissions, can we really put a price on that? Plus, as technology continues to advance and more electric cars hit the roads, we can only hope that the cost of batteries will eventually come down. After all, as the old saying goes, you’ve got to spend money to save money – and the same holds true for saving the planet.

“

FAQs

Why are electric car batteries more expensive than traditional car batteries?

Electric car batteries are more expensive than traditional car batteries because they use advanced technology and require a combination of rare metals, such as lithium and cobalt, which are expensive to mine and refine.

Can the cost of electric car batteries be expected to come down in the near future?

Yes, the cost of electric car batteries is expected to come down in the near future with advances in technology and improved economies of scale from increased production.

Are there any government programs or incentives available to help offset the cost of electric car batteries?

Yes, some governments offer programs or incentives to help offset the cost of electric car batteries, such as tax credits, rebates, or grants for purchasing or installing charging stations.

How long does an electric car battery typically last before needing to be replaced?

Electric car batteries typically last between 8-10 years or 100,000-200,000 miles before needing to be replaced, depending on usage and maintenance. However, advancements in battery technology may extend their lifespan in the future.