Rev Up Your Drive with the Revolutionary Functional Unit of Electric Car Batteries

Electric cars are becoming increasingly popular, and as a result, so is the need for high-quality batteries. These batteries function as the heart of the vehicle, providing power to the electric motor that propels it forward. But what exactly is an electric car battery, and how does it function as a functional unit? In this blog, we will delve into the essential components of electric car batteries and explain how they work as a cohesive whole to power your vehicle.

From the anode and cathode to the electrolyte solution, we will provide an in-depth look at each component’s function and how they work together to create a reliable, efficient, and long-lasting battery. So buckle up and get ready to dive into the world of electric car batteries.

Overview of Electric Car Batteries

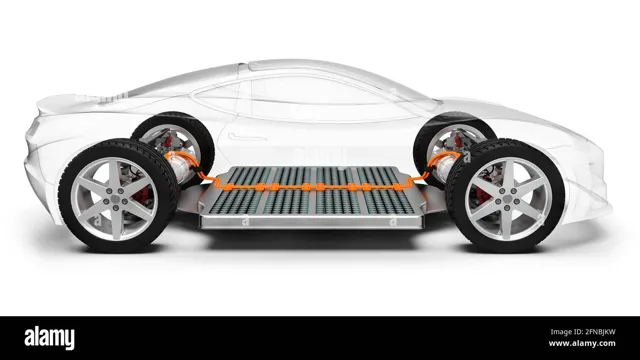

When it comes to electric cars, the battery is the functional unit that makes everything possible. Electric car batteries are made up of numerous smaller cells that work together to provide power to the vehicle. These cells store energy in chemical form and then release it when needed to drive the car’s electric motor.

The most commonly used battery type in electric cars today is the lithium-ion battery, which is known for its high energy density and long cycle life. To keep the battery functioning optimally, it is important to keep it charged between 20% and 80% of its capacity and to avoid exposing it to extreme temperatures. Proper maintenance of the battery can extend its life and help ensure that the vehicle continues to perform at a high level for years to come.

Overall, the electric car battery is a critical component of these vehicles and is essential to their performance and sustainability.

Introduction to Battery Functional Units

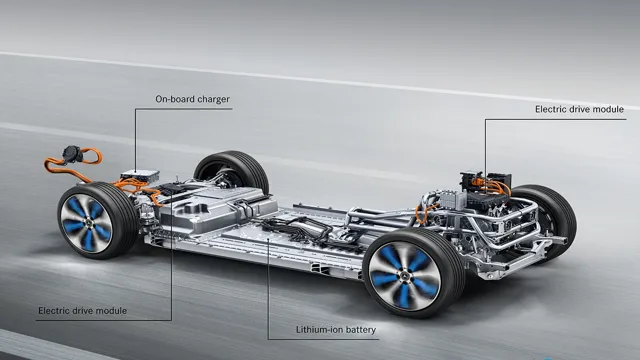

Electric car batteries are fascinating pieces of technology that power the electric vehicles we see on the roads today. These batteries consist of multiple functional units that work together to store and deliver electrical power. The key functional units include the cells, modules, and packs.

Cells are the basic building blocks of the battery that store electrical energy and are connected together to form modules. These modules are then connected to one another to form packs, which are the largest functioning units in the battery. The packs are responsible for storing and delivering electrical power to the car’s electric motor.

One of the best things about electric car batteries is that they allow us to drive without emissions and without consuming fossil fuels. So, they play an important role in reducing pollution and combating climate change. As electric cars become more popular and affordable, we can expect to see even more advances in battery technology that make them even more efficient and sustainable.

Composition and Structure of Battery Units

Electric car batteries are complex units that power electric vehicles. A typical battery is made up of several smaller battery units called cells. Each cell is composed of a positive electrode, a negative electrode, and an electrolyte.

The electrodes are made up of graphite and lithium cobalt oxide respectively. When the battery is charged, lithium ions move from the positive electrode to the negative electrode through the electrolyte. During discharge, the opposite happens, with lithium ions moving from the negative electrode to the positive electrode.

This movement of ions generates the flow of electricity that powers the electric motor of the vehicle. The size of the battery and the number of cells used determine the range of an electric car. High-end electric cars use larger and more powerful batteries to achieve a longer range while smaller electric vehicles have smaller batteries and hence a shorter range.

With advances in technology, manufacturers are developing batteries that are more efficient, durable, and affordable to make electric vehicles more accessible to the common person.

Battery Management Systems

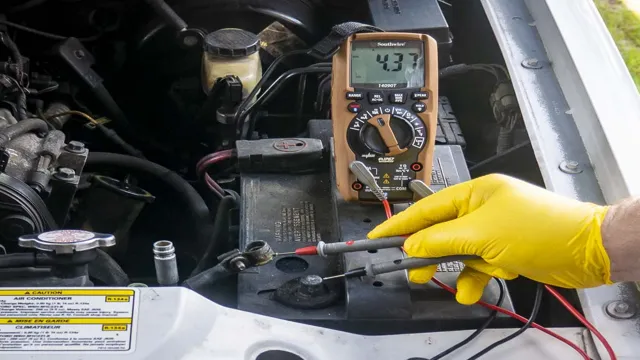

Battery management systems (BMS) are a crucial component of electric car battery functional units. These systems are responsible for ensuring the safe and efficient operation of electric car batteries during charging and discharging cycles. BMS use complex algorithms and sensors to monitor the health of the battery, measure its state of charge and state of health, balance individual cell voltages, and prevent overcharging or overheating of the battery.

If a battery becomes damaged or fails, the BMS can detect this and shut down the battery to prevent further damage or risk of fire. Think of the BMS as the brain of an electric car battery; it monitors and controls the various functions of the battery to ensure it operates correctly and safely. Without a properly functioning BMS, an electric car battery would be at risk of damage or failure, which could lead to safety issues for the driver and passengers.

Role of BMS in Maintaining Battery Health

Battery Management Systems A battery management system (BMS) is an essential tool for maintaining the health of a battery. It’s responsible for monitoring and controlling the battery’s charging and discharging cycles to ensure that it operates within the safe range of its chemical and physical limits. The BMS also helps to keep the battery balanced by preventing overcharging or undercharging of individual cells, which can lead to reduced capacity and a shorter lifespan.

By constantly analyzing the battery’s performance and providing real-time feedback, the BMS enables users to identify potential issues and take corrective action before they affect the battery’s overall health and longevity. In short, the BMS is crucial for ensuring that batteries remain reliable, efficient, and safe over the long run, whether they power electric vehicles, stationary energy storage systems, or other applications.

Functions and Components of BMS

Battery Management Systems (BMS) Battery Management Systems (BMS) play a critical role in monitoring and managing the performance of rechargeable batteries. It consists of several functions and components that work collaboratively to ensure battery health, prevent overcharging and over-discharging, improve longevity, and optimize overall efficiency. Some of the main components of BMS include a microcontroller, sensors, cell balancing circuits, battery protection circuits, and communication interfaces.

The microcontroller carries out essential functions such as monitoring the State of Charge (SoC) and State of Health (SoH) of the battery, controlling charging and discharging, and communicating with other components. The sensors provide real-time measurements of critical parameters such as voltage, current, temperature, and impedance. Cell balancing circuits maintain the voltage balance of individual cells in the battery pack, while the battery protection circuits prevent overcharging, over-discharging, and short-circuiting.

Communication interfaces such as CAN, LIN, and UART allow the BMS to communicate with external systems such as the vehicle’s engine management system. In summary, BMS is a sophisticated system that employs advanced technologies and algorithms to manage the critical aspects of battery performance, ensuring optimal operation, safety, and longevity.

Importance of BMS in Maximizing Battery Life

A battery management system (BMS) is an essential component in maximizing the service life of a battery. It not only monitors and maintains the battery’s state of charge but also regulates the charge and discharge process to ensure optimal battery performance. BMS protects the battery from overcharging, deep discharging, and high temperatures, which can all lead to premature battery failure.

By maximizing battery life, a BMS also increases the battery’s capacity to store and release energy, making it an integral part of any battery-powered system. A BMS enables efficient use of energy and reduces the risk of damaging the battery, ultimately saving money and prolonging the life of the battery. Without BMS, the battery will not be able to provide reliable and safe operation over its intended lifespan.

Therefore, investing in a high-quality BMS is crucial for anyone who wants to get the most out of their battery-powered devices.

Charging and Discharging of Batteries

Electric car batteries are the functional units that power the vehicles we use every day. These batteries are responsible for providing the energy needed to propel the car forward, and just like any other battery, they need to be charged and discharged to function properly. When an electric car battery is charged, an electric current is sent through the battery, which causes the chemical compounds inside it to store energy.

When the battery is then used to power the car, the energy is released, and the battery begins to discharge. It’s important to note that batteries can only hold a limited amount of charge, which means that they will eventually need to be recharged before they can be used again. By understanding the charging and discharging process of electric car batteries, we can better understand how to take care of these functional units to ensure that they remain in top working order for as long as possible.

Types of Charging and Discharging

Charging and discharging are the two essential operations of batteries. Charging batteries helps their cells to regain their lost charge and provide power. This means that charging the battery helps it to restore its capacity to generate energy and perform its intended function.

Similarly, the discharging process refers to the battery’s capacity to use stored energy to deliver power output. Discharging batteries allows them to transform the stored energy into useful work, such as driving an electric vehicle or powering a device. There are different types of charging and discharging to achieve efficient battery life and performance, such as constant-current charging, constant-voltage, and trickle charge.

Choosing the appropriate charging and discharging method for a battery’s chemistry, voltage, and capacity is critical. Therefore, understanding how charging and discharging works can significantly help extend the lifespan of batteries.

How to Maximize Battery Performance

When it comes to maximizing battery performance, understanding the charging and discharging process is crucial. First off, it’s important to know that not all batteries are created equal, and each type may have different charging and discharging requirements. However, in general, it’s best to avoid letting the battery completely discharge as it can cause irreversible damage to the battery’s cells.

Instead, it’s recommended to charge the battery when it reaches around 20-30% capacity. Additionally, overcharging the battery can also lead to damage, so it’s important to monitor the charging process and unplug the device when it reaches 100%. It’s also a good idea to use the original charger that came with the device, as using a different charger can result in slower charging speeds or even damage the battery.

By following these simple guidelines, you can maximize the lifespan and performance of your batteries.

The Future of Electric Car Batteries

The future of electric car batteries is constantly evolving, and the key to unlocking their full potential lies in the electric car battery functional unit. This unit consists of the battery cells, cooling system, and battery management system working together to optimize the battery’s performance and durability. As technology advances, we can expect more efficient and powerful battery cells to become available, allowing for longer driving ranges and faster charging times.

However, it’s not just about increasing output – the cooling system is also essential to maintaining the battery’s temperature and preventing overheating, which can damage the cells and shorten the battery’s lifespan. Likewise, the battery management system is crucial for ensuring the battery’s safety and maximizing its lifespan by monitoring parameters such as charging and discharging rates, temperature, and state of charge. Overall, the electric car battery functional unit is the foundation of the electric vehicle industry, and continued advancements in this space will pave the way for a cleaner, more sustainable future.

Advancements and Innovations in Battery Technology

Electric car batteries have come a long way in recent years, and advancements in technology have made them even more impressive. One of the most promising innovations in electric car battery technology is the development of solid-state batteries. These batteries have a higher energy density and faster charging times than traditional lithium-ion batteries.

Solid-state batteries also have a longer lifespan, which means fewer replacements and less waste. Another exciting development is the use of recycled materials in battery production. This not only reduces the environmental impact of battery manufacturing but also makes electric cars more sustainable.

With these advancements and more on the horizon, the future looks bright for electric cars and their batteries.

The Role of Electric Cars in Carbon Footprint Reduction

Electric car batteries are at the forefront of innovative technology and have enormous potential in reducing our carbon footprint. The future of electric car batteries promises improved performance and longer ranges, which make them more convenient, reliable, and accessible to everyone. These batteries offer a cleaner, non-polluting alternative to fossil fuels that can help mitigate the effects of climate change.

As we transition towards a greener, more sustainable future, electric cars will undoubtedly play a critical role in reducing greenhouse gas emissions. Furthermore, advances in electric car batteries can also translate to other areas and industries, such as renewable energy storage solutions. With electric car batteries, we can create a more environmentally friendly world that benefits everyone.

Are you ready to make a positive impact on our planet by embracing electric cars and their batteries?

Conclusion

In conclusion, the electric car battery can be seen as the functional unit that electrifies our ability to roam free, unencumbered by the limitations of fossil fuels. It’s truly the power-push behind the surge towards greener, cleaner transportation options. With its charging capabilities and ability to hold a charge, this essential piece of the electric car puzzle is the key to unleashing a future where efficiency and sustainability reign supreme.

Let’s charge ahead and power up our lives with the electric car battery!”

FAQs

What is a functional unit for an electric car battery?

The functional unit for an electric car battery is a kilowatt-hour (kWh) of electrical energy storage.

How long does an electric car battery typically last?

An electric car battery typically lasts for 100,000 to 200,000 miles, or around 8 to 10 years, before needing to be replaced.

What factors affect the lifespan of an electric car battery?

The lifespan of an electric car battery can be influenced by factors such as temperature, frequency of use, charging habits, and the quality of the battery itself.

Can electric car batteries be recycled?

Yes, electric car batteries can be recycled. The materials in the batteries can be reused to create new batteries or other products, reducing the environmental impact of battery disposal.