The Future of Electric Vehicles: Exploring the Rise of Battery Gigafactories

Have you ever wondered how electric cars can go for miles and miles, yet never need to stop for gas? The answer is the electric car battery gigafactories, of course! These massive facilities are popping up all over the world, changing the game for the future of transportation. In this blog post, we’ll dive into the details of these gigafactories, exploring what they are, why they’re important, and where they’re located. So buckle up, and let’s take a closer look at the revolution that is electric vehicle battery production!

What are they?

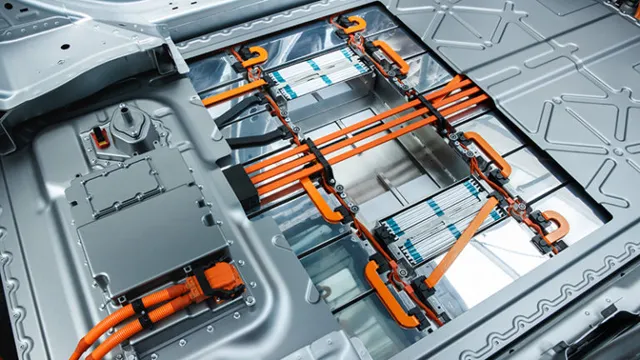

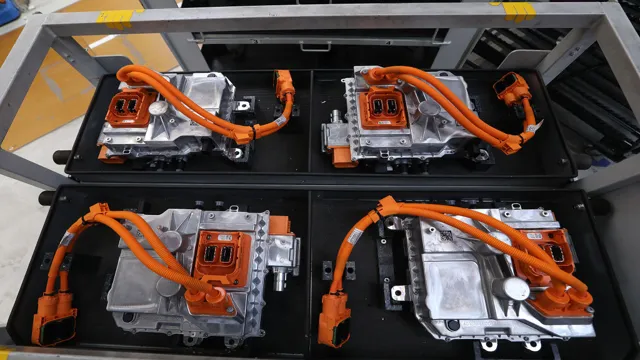

Electric car battery gigafactories are massive manufacturing facilities built specifically for the purpose of producing high-capacity batteries for electric vehicles. These factories are typically operated by established auto manufacturers or battery companies, who invest heavily in their construction in order to meet the growing global demand for electric vehicles. Gigafactories use highly-automated production lines and specialized equipment to produce large quantities of batteries quickly and efficiently.

The most well-known of these gigafactories is Tesla’s Gigafactory, which is currently the largest lithium-ion battery factory in the world. With numerous countries setting ambitious goals for electric vehicle adoption, the race to build gigafactories is on, and many new facilities are expected to pop up in the coming years. These facilities will be key to the rapid adoption of electric cars, with the potential to significantly reduce their cost and improve their range.

Explanation and Importance of Gigafactories

Gigafactories are super-sized manufacturing facilities that produce large quantities of batteries, electric vehicles, and renewable energy products. These gigafactories play a significant role in driving the renewable energy revolution forward. Essentially, they are factories that put the “mega” in manufacturing, producing large-scale products in massive quantities.

One of the main functions of a gigafactory is to streamline the production process and reduce costs, making it possible to manufacture products on an unprecedented scale and at a cheaper cost. Gigafactories are significant because they help reduce dependency on fossil fuels, making it possible to shift towards renewable energy sources and reduce our carbon footprint. Additionally, with the growing demand for electric cars and renewable energy systems, gigafactories offer a reliable and efficient means of meeting this demand.

With an increase in gigafactory production, we can expect to see a reduction in greenhouse gas emissions and progress towards a cleaner, more sustainable future.

Tesla and Gigafactories

When it comes to electric cars, one of the biggest advancements has been the development of gigafactories. These massive facilities, pioneered by Tesla, are designed to produce a massive amount of electric car batteries. The idea behind the gigafactories is to reduce the cost of producing electric car batteries by increasing the scale of production.

With the increased scale, the hope is that the cost of batteries will drop, making electric vehicles more affordable for consumers. Tesla’s first gigafactory was built in Nevada, and the company has plans to build more around the world. In addition to Tesla, other automakers and battery companies are also exploring the concept of gigafactories, as they recognize the potential for improving the affordability and accessibility of electric vehicles.

Overall, the concept of gigafactories is an exciting development for the electric vehicle industry and offers hope for a cleaner and more sustainable future for transportation.

How Tesla is Revolutionizing the Industry

In just a few years, Tesla has become a household name. The automaker has revolutionized the electric car industry and promised to make it accessible to everyone. One of Tesla’s main strategies is the use of “Gigafactories.

” These massive facilities produce batteries for electric cars on a scale never seen before. The first Gigafactory, located in Nevada, covers 3 million square feet and employs over 7,000 people.

It’s capable of producing enough batteries to power 500,000 vehicles per year. Tesla is already building another Gigafactory in Shanghai, and plans for a third in Berlin have been announced. With the use of Gigafactories, Tesla hopes to expand electric car production and lower the cost of batteries, making electric cars more affordable for the average consumer.

All in all, Tesla has set its sights on changing the way we think about cars, and the Gigafactories are a significant piece of the puzzle.

The Role of Gigafactories in Tesla’s Success

When it comes to Tesla’s success, one cannot overlook the crucial role played by its gigafactories. These massive manufacturing plants are specifically designed to produce high volumes of electric vehicles and energy storage solutions at a lower cost, giving Tesla an edge over its competitors in terms of both production efficiency and profitability. Additionally, by producing their own batteries on-site, Tesla is able to reduce supply chain vulnerabilities and minimize transportation costs associated with shipping batteries from other suppliers.

The combination of these factors not only allows Tesla to offer their products at a lower price point, but also helps them stay ahead of the competition in an industry that is rapidly evolving. In short, Tesla’s gigafactories are an integral part of their success, providing them with the necessary tools to continue leading the charge towards a more sustainable future.

Global Gigafactories

Electric car battery gigafactories are rapidly emerging around the globe as the electric vehicle market continues to boom. These factories produce large numbers of batteries to power electric vehicles and are essential in meeting the ever-increasing demand for electric cars. Gigafactories streamline the production process, reduce costs, and speed up production time.

They also allow for greater control over the supply chain, ensuring a constant supply of high-quality batteries. The world’s largest electric car battery gigafactory is currently Tesla’s Gigafactory in Nevada. However, more and more companies are investing in their own gigafactories, such as LG Chem in Poland, CATL in Germany, and SK Innovation in the United States.

With the rapid increase in electric vehicle demand, these gigafactories are essential to ensure the continued growth and success of the electric car industry.

Locations and Capacity of Gigafactories Around the World

Gigafactories have become a crucial part of the automotive industry, especially with the increasing demand for electric vehicles. Tesla’s Gigafactory based in Nevada, with a capacity exceeding 35 GWh per year, is the most prominent gigafactory globally. However, there are other massive and impressive gigafactories around the world.

LG Chem in South Korea is one of the most prominent battery manufacturers globally, with factories in South Korea, China, and the United States, with a total of 70 GWh capacity. China’s CATL has also built production facilities globally, with a cumulative production capacity of 58 GWh. Meanwhile, Northvolt in Sweden has a gigafactory in progress that is set to produce 40 GWh capacity batteries per year once it becomes operational.

Gigafactories will continue playing a substantial role in reducing carbon emissions, and with the growing popularity of electric vehicles, we can expect to see more of these massive facilities sprouting up globally.

Impact of Gigafactories on Local Economies

Gigafactories Gigafactories have become a game-changer in the world economy, especially in the world of clean energy. These factories produce large quantities of batteries for electric vehicles and other devices that use renewable energy. The emergence of gigafactories has brought economic benefits to the local areas where they are located.

These factories have created thousands of jobs, boosted the demand for local businesses and contributed to the tax revenue of the government. For instance, Tesla’s Gigafactory 1 in Nevada employs around 7,000 people, and it is estimated that it has generated $6 billion in economic activity in the state of Nevada. Similarly, Samsung’s battery Gigafactory in Hungary has created 2,600 direct jobs and an additional 10,000 indirect jobs.

The construction and development of these factories have also attracted more investment and business. In conclusion, the impact of gigafactories on local economies cannot be overemphasized. These factories have brought positive economic growth to the areas where they are located, and they are sure to continue to do so in the future.

Future of Gigafactories

Electric car battery gigafactories are the future of the automotive industry. In recent years, the demand for electric vehicles has skyrocketed and shows no signs of slowing down. As a result, manufacturers are digging deeper into the development of battery technology and increasing production.

The term ‘gigafactory’ has been coined to describe these factories, which produce electric car batteries on a massive scale. The hope is that gigafactories will help drive down costs, making sustainable transportation more accessible to consumers. These factories will help ensure a sustainable supply of the raw materials required for battery production and will reduce the environmental impact of lithium-ion battery production.

As electric vehicles become more affordable and accessible, gigafactories will become even more important to meet the growing demand. With its commitment to build two more gigafactories in the US, Tesla has set the standard for other manufacturers to follow. As a result, the future of gigafactories looks bright, as companies invest in battery technology to keep pace with the electrification of transportation.

Potential for Increased Adoption and Expansion

The future of gigafactories is exciting, with the potential for increased adoption and expansion. As demand for electric vehicles (EVs) continues to rise, there is a growing need for more efficient and cost-effective production of batteries. Gigafactories are a key solution to this challenge, offering economies of scale and streamlined production processes.

With the success of Tesla’s Gigafactory 1, more companies are now investing in their own gigafactories, which will only accelerate the trend towards greater electrification of transportation. As these factories become more common, we can expect to see further decreases in the cost of batteries and, by extension, EVs. This will make EVs more accessible to the general public and lead to a more sustainable future.

Overall, the future of gigafactories looks extremely bright and promising, and we can expect to see more of these mega-factories popping up in the coming years.

Innovation and Advancements in Battery Technology

Gigafactories Gigafactories are the future of battery technology. These massive factories are dedicated to producing batteries on a large scale, helping to meet the growing demand for energy storage. With the rise of electric vehicles and renewable energy, the demand for batteries is skyrocketing.

In response, companies like Tesla, LG, and Panasonic have made a significant investment in building gigafactories. These factories have the potential to revolutionize the industry by increasing production efficiency and driving down costs. They also allow for the production of more advanced batteries, such as solid-state batteries, which promise to deliver higher energy density and faster charging times.

Gigafactories are a crucial step towards a sustainable future, and with advancements in technology, the possibilities are endless.

Conclusion

In conclusion, it’s clear that gigafactories are the spark that will ignite the electric car revolution. By churning out batteries on a massive scale, we’ll see costs come down, range go up, and more and more people ditch their gas-guzzlers for sleek and sustainable electric cars. So let’s charge ahead, drive change, and plug in to a brighter, cleaner future.

After all, it’s electrifying!”

FAQs

What is an electric car battery gigafactory?

An electric car battery gigafactory is a manufacturing plant that produces large quantities of batteries used specifically for electric vehicles.

Who are some of the major companies that have built electric car battery gigafactories?

Some of the major companies that have built electric car battery gigafactories include Tesla, LG Chem, and CATL.

Why are electric car battery gigafactories important?

Electric car battery gigafactories are important because they help to increase the production of electric cars, making them more accessible and affordable for consumers. They also help to reduce greenhouse gas emissions and promote a cleaner environment.

What advancements are being made in electric car battery gigafactories?

Advancements in electric car battery gigafactories include the use of new materials for battery production, improvements in battery performance and efficiency, and the development of more sustainable and eco-friendly manufacturing processes.