Lithium Mining: Powering the Future of Electric Car Batteries

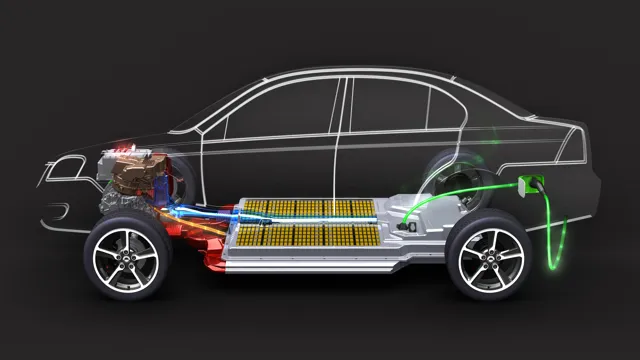

Are you curious about the electric car battery and how it works? Many people don’t realize that one of the essential components of an electric car is the lithium-ion battery. These batteries are what power the vehicle, and without them, electric cars wouldn’t exist. However, many people overlook the fact that lithium is a finite resource that needs to be mined from the earth.

In this blog, we’ll be discussing the process of mining lithium, the impact it has on the environment, and how it affects the production of electric cars. Mining lithium is a complex process that involves extracting it from brine pools or hard rock deposits. While the process of extracting lithium varies depending on the method, it typically involves a lot of water, chemicals, and energy.

This extraction process can result in significant damage to the environment, including the depletion of groundwater and pollution of nearby ecosystems. The impact of lithium mining on the environment is concerning, but it’s important to consider its role in the production of electric cars. The majority of electric cars run on lithium-ion batteries, making it a crucial component in the industry.

As the popularity of electric cars continues to grow, there will be an increased demand for lithium. However, this demand can put a strain on the environment, making it essential to find more sustainable and environmentally-friendly ways of mining lithium. Overall, understanding the impact of lithium mining on the environment and its role in electric car production is critical.

As consumers, it’s important to be aware of the resources that go into the products we use and the impact they have on the environment. By taking steps to support sustainable production methods and being mindful of our energy consumption, we can help reduce the negative impacts of lithium mining and work towards a more environmentally-friendly future.

What is Lithium?

Electric car battery technology has come a long way in recent years, and one of the keys to this progress is the mineral lithium. Lithium is a soft, silver-white metal that is used in rechargeable lithium-ion batteries, which are the power sources that keep many electric cars moving. Today, the majority of lithium used in battery production comes from mining operations that extract it from rocks and brines.

Because of the increasing demand for electric vehicles and other lithium-based technologies, many countries are ramping up their lithium mining efforts, hoping to secure a supply of this valuable mineral for the future. However, some environmental experts are concerned about the impact of lithium mining on local ecosystems and water resources. Despite these concerns, the lithium industry is expected to continue growing in the coming years, as more and more companies invest in the development of electric cars and other lithium-powered devices.

Properties and Characteristics

Lithium is an element that belongs to the alkali metal group, and it is the lightest of all metals. Its atomic number is 3, and its symbol is Li. Lithium is a soft, silver-white metal that is highly reactive and can catch fire spontaneously when exposed to air or water.

This high reactivity is due to its electron configuration, which makes it highly prone to lose an electron and form a positive ion. Lithium is commonly used in batteries, particularly in rechargeable batteries for devices such as smartphones and laptops. It is also used in various applications such as pharmaceuticals, ceramics, and lubricants.

One of the most significant properties of lithium is its low density, which gives it a unique advantage over other metals in weight-sensitive applications. Additionally, lithium has excellent heat and electrical conductivity, making it a popular choice for electronic applications. Overall, lithium is a highly versatile and valuable element with numerous properties and characteristics that make it essential in a wide range of industrial and commercial applications.

Why is Lithium Important for Electric Car Batteries?

Electric car battery lithium mining is crucial for the production of electric vehicles (EVs), given that lithium is a key component in their batteries. The high efficiency, durability, and relatively lower cost of lithium-ion batteries make them a popular choice among EV manufacturers. Lithium mining involves extracting the metal from the earth’s crust, and while it is a challenging and costly process, the environmental impacts are considerably less than traditional fossil fuel mining.

From an economic perspective, the demand for electric cars is expected to rise dramatically in the coming years, which will increase the demand for lithium mining. Nevertheless, the potential long-term damage to the environment and public health from lithium mining should be addressed, and more sustainable practices must be implemented. In any case, lithium remains one of the key materials needed for electric car batteries, and the mining of it will continue to be an essential factor in the growth of the EV industry.

Advantages over Other Battery Types

Lithium is a crucial component in the world of electric vehicle batteries due to its many advantages over other battery types. Lithium-ion batteries are lighter, smaller, and able to store more energy than traditional lead-acid batteries. They also have a longer lifespan and can charge much faster, making them ideal for powering electric vehicles.

Lithium-ion batteries are also more environmentally friendly, producing fewer pollutants during production and disposal. Furthermore, lithium is a highly abundant element, making it a sustainable and reliable source for battery production in the future. With all these advantages, it’s clear why lithium plays a crucial role in the development of electric car batteries, helping to pave the way for a cleaner, more sustainable future.

Demand for Lithium in Electric Car Production

The demand for lithium in electric car production has shot up due to its importance in creating electric car batteries. Lithium is a lightweight metal with high electrochemical potential, making it useful for powering electric vehicles. Lithium-ion batteries are highly efficient when compared to traditional batteries, as they are able to store more energy and are more durable.

Lithium-ion batteries have a high energy density, meaning they can store more energy in a smaller size. This is crucial for electric cars as it allows them to have a longer driving range while maintaining a smaller battery size. The amount of lithium required to produce these batteries has increased drastically in recent years, as the popularity of electric vehicles grows.

In fact, lithium demand is predicted to triple by 2025 due to the increased demand for electric vehicles. This means that the need for lithium will continue to rise, making it a highly sought after commodity in the automotive industry.

Types of Lithium Mining

When it comes to electric car battery lithium mining, there are a few different types of mining methods used to extract this valuable resource. The most common method is called brine mining, which involves pumping lithium-rich brine from underground into evaporation ponds. As the water evaporates, the lithium is left behind and can be harvested.

Another method is hard rock mining, which involves drilling into solid rock formations to extract lithium-containing minerals. This can be more difficult and expensive than brine mining, but it can also yield higher-quality lithium. There are also newer methods being developed, such as clay mining, which involves extracting lithium from clay deposits, and geothermal mining, which involves tapping into geothermal energy sources to extract lithium.

As the demand for electric car batteries continues to grow, it is important that we explore all of these methods in order to ensure a sustainable and ethical supply of lithium for years to come.

Brine Extraction

Brine extraction is one of the most common methods used for lithium mining. Brines are saltwater solutions that contain high levels of lithium. Large deposits of brines can be found in salt flats or salars, mostly in South America, and these are often the sources of lithium production.

There are generally two types of brine extraction methods: pumping and solar evaporation. Pumping involves extracting the brine from deep underground using wells, while solar evaporation involves letting the brine sit on the surface in large ponds and allowing the sun to evaporate the water, leaving behind the lithium and other minerals. Both methods have advantages and disadvantages, and the choice depends on factors such as the concentration of lithium in the brine, the location, and the availability of resources.

Hard Rock Mining

When it comes to mining lithium, there are two main types of operations: hard rock mining and brine extraction. Hard rock mining involves excavating solid rock formations that contain lithium, such as granites and pegmatites. The method requires drilling and blasting to extract the ore, which is then transported to a processing plant for further treatment.

Underground and open pit mining are both used in hard rock mining, depending on the size and depth of the deposit. One advantage of hard rock mining is that it produces higher-grade lithium concentrate, but it can be more expensive and environmentally damaging. Overall, it is essential to weigh the pros and cons of each mining method to ensure that the lithium industry can meet the growing demand for this critical mineral.

Environmental Impact of Lithium Mining

When we think about electric cars, we often imagine a more sustainable future. However, we also need to consider the impact of the materials used to power those cars. Electric car batteries, for example, rely heavily on lithium mining.

While lithium is a plentiful resource, the process of extraction can have significant environmental impacts. Lithium mining requires a vast amount of water, which can be especially problematic in arid regions where it is often located. The process also produces substantial amounts of waste, which can pollute local ecosystems and have long-lasting effects.

To truly achieve sustainable transportation, we need to explore alternative materials and methods for powering electric cars. While lithium will likely remain a part of the equation, we must also consider the environmental costs associated with its extraction.

Water and Soil Contamination

Lithium mining has a significant environmental impact on our planet, particularly regarding water and soil contamination. The process of lithium extraction is highly water-intensive, and the chemicals used can seep into groundwater, which contaminates the water supply. Furthermore, the excavation of lithium-rich soil can cause soil erosion, making it more susceptible to heavy metal contamination and decreasing soil fertility.

This can have a highly negative impact on plant and animal life in the surrounding environment. We must consider the consequences of lithium mining and work towards developing more sustainable and environmentally-friendly methods of obtaining this valuable resource. By doing so, we can protect our planet’s delicate ecosystems and ensure that future generations inherit a healthy and sustainable environment.

Disruption to Local Communities

Lithium mining is an activity that has been hailed as a solution to meet the growing demand for batteries in electronic devices and vehicles. However, this activity comes with significant environmental impacts, including disruptions to local communities. Lithium mining requires the extraction of large amounts of water, which can lead to water scarcity in areas with already limited water resources.

Moreover, the extraction process often involves the use of toxic chemicals, which can contaminate nearby ecosystems and harm aquatic life. Lithium mining can also take a toll on indigenous communities, as it disrupts their traditional way of life, including their access to natural resources and sacred sites. Therefore, it is crucial for lithium mining companies to consider the environmental and social impacts of their activities and adopt sustainable practices that minimize the negative effects.

Sustainable Lithium Mining Practices

Electric car battery lithium mining is a growing industry that has the potential to help reduce the carbon footprint of the transportation sector. However, the mining of lithium can also have negative environmental impacts if not managed sustainably. Fortunately, there are several sustainable lithium mining practices that are being implemented by companies in the industry.

One practice is the use of brine extraction, which involves pumping brine out of underground aquifers and then evaporating the water to concentrate the lithium. This method is less disruptive to the surrounding landscape than traditional hard rock mining. Other companies are exploring the use of renewable energy sources to power their mining operations, further reducing their environmental impact.

Ultimately, the adoption of sustainable lithium mining practices will be essential to ensure the long-term viability of the electric car industry, while also protecting the environment.

Efforts to Reduce Environmental Impact

As demand for lithium batteries continues to rise, there is growing concern over the environmental impact of the lithium mining industry. However, efforts are being made to reduce this impact through sustainable lithium mining practices. One such practice is the use of brine pools for lithium extraction, which reduces water usage and the associated risk of water pollution.

Additionally, underground lithium mining methods that require less energy and produce fewer greenhouse gas emissions are being explored. Companies are also investing in recycling technologies to reduce the need for new lithium mining altogether. By implementing these sustainable practices, the lithium mining industry can continue to meet the demand for lithium while minimizing its impact on the environment.

Investment in Recycling Technology

Investment in recycling technology has played a vital role in improving sustainability and reducing environmental impact in many industries, including the lithium mining industry. Sustainable lithium mining practices involve various methods of reducing waste and reusing resources, which all depend on significant investment in recycling technology. Recycling technology provides a viable solution that helps companies cut down on the environmental impact of lithium mining by finding innovative ways to recycle resources and minimize the amount of waste produced in the process.

Investing in sustainable lithium mining practices has become an essential factor in ensuring that the industry adopts eco-friendly methods that are both cost-effective and environmentally beneficial. With the increasing demand for electric vehicles and lithium-ion batteries, companies that invest in sustainable mining practices have the potential to make smart investments that will provide long-term benefits while building reputations for environmental responsibility.

Conclusion

In conclusion, mining lithium for electric car batteries may not be the most glamorous aspect of the green revolution, but it is a necessary one. Just like how every superhero needs a dependable sidekick, every electric car needs a powerful and long-lasting battery to keep it going. So let’s mine lithium with the sustainable and responsible practices the Earth deserves, and zzoom off into a cleaner, greener future!”

FAQs

What is an electric car battery made of?

An electric car battery is typically made of lithium-ion cells that store and discharge energy to power the vehicle.

Why is lithium mining important for electric car batteries?

Lithium is a critical component of electric car batteries because it has a high energy density, enabling the battery to store more energy per unit weight. Mining lithium is necessary to obtain this material for battery production.

Are there any environmental concerns with lithium mining?

Yes, there are some environmental concerns with lithium mining. Extracting lithium can require large amounts of water and energy, and mining can disrupt local ecosystems. However, efforts are underway to make lithium mining more sustainable and reduce its environmental impact.

How long do electric car batteries typically last?

The lifespan of an electric car battery can depend on a variety of factors, including the specific battery chemistry, usage patterns, and environmental conditions. However, many electric car batteries are designed to last for several years and can be replaced if necessary.