Energize Your Ride: The Fascinating Process of Electric Car Battery Making

Electric cars are becoming increasingly popular as people realize the harmful environmental impacts of traditional gasoline-powered vehicles. However, a critical component of electric cars is their battery, which provides the power that runs the electric motor. Therefore, the manufacturing of electric car batteries is a critical process that requires specialized knowledge and expertise.

In this blog, we will explore the complexities of electric car battery making and the significance of the process for the future of sustainable transportation. Join us on this journey to learn more!

The Importance of Electric Car Battery Technology

Electric car battery making has revolutionized the automotive industry, with its importance integral to the success and future of electric vehicles. The limitations of range and charging time are major factors holding back electric vehicles and battery technology has the potential to overcome these issues. The development of new technology has led to advancements in electric car batteries, including higher energy density, faster charging times, and longer-lasting batteries.

These advancements have led to the production of electric cars that are more affordable, convenient, and reliable. The use of recycled materials in battery production has also decreased the environmental impact of the manufacturing process. Therefore, the development of electric car battery technology is crucial to the future of transportation and to achieve a sustainable environment.

Saving on Fuel Costs

Electric car battery technology plays a vital role in saving on fuel costs and reducing carbon emissions. These batteries rely on electricity instead of gasoline or diesel, making them more cost-effective since electricity is generally cheaper than standard fuels. Additionally, electric cars have regenerative braking systems that recover energy lost during braking, further increasing their efficiency.

With advancements in battery technology, electric cars can drive longer distances and charge faster, making them more practical for long trips. In the near future, we may even see battery swapping stations that allow electric car owners to switch out their batteries quickly like refueling at a gas station. Investing in this technology can save you a lot of money in the long run while also protecting the environment.

So, when you’re considering your next vehicle purchase, consider going electric and take advantage of the latest battery technology.

Fighting Climate Change

Electric Car Battery Technology If there’s one thing that could revolutionize the fight against climate change and make a significant impact on our environment, it’s electric car battery technology. The switch from gas-powered cars to electric cars is crucial in reducing carbon emissions and protecting our planet. However, without effective battery technology, electric cars would only be a temporary solution.

That’s where the importance of electric car battery technology comes in. Battery advancements have allowed electric cars to travel further than ever before, and the production of more sustainable, recyclable batteries is becoming a key area of focus for manufacturers. As technology improves, the cost of batteries is also expected to drop, making electric cars more accessible for the average consumer.

So, while electric cars are already making a positive impact, it’s the continued advancements in battery technology that will truly make a difference in the fight against climate change.

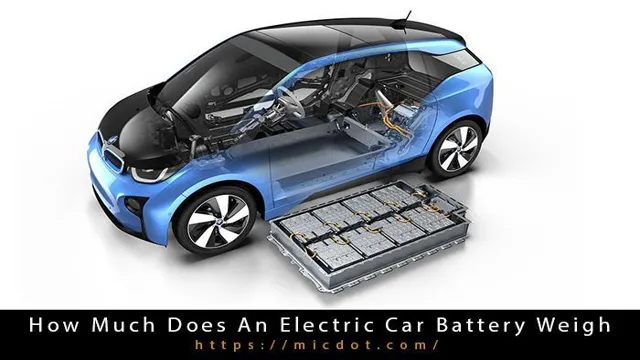

The Basics of Electric Car Battery Production

Have you ever wondered how electric car batteries are made? Well, the process starts with the collection of raw materials such as lithium, cobalt, and nickel, which are mainly found in South America, Australia, and Africa. These materials are then transported to battery production plants where they undergo a series of processes. First, they are purified and transformed into a cathode, anode, and electrolyte.

These three parts are then assembled and placed inside a protective casing. Finally, the battery is tested and packaged before being shipped to manufacturers. The production of electric car batteries is a complex process that involves advanced technology, but it is essential for the growth of the electric car industry.

With the increased demand for sustainable transportation, companies are investing heavily in battery production to meet the growing needs of consumers.

Materials Used in Battery Cells

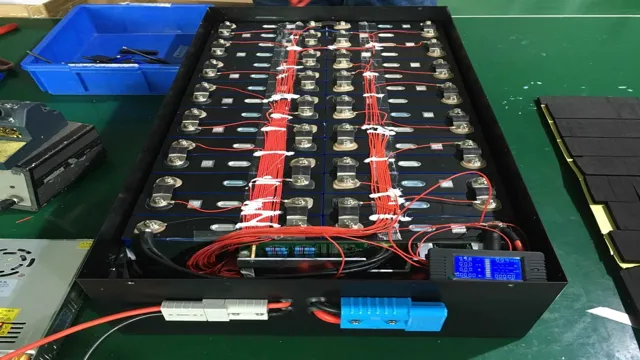

When it comes to electric car battery production, it’s all about the materials used in battery cells. These cells are the building blocks of the battery, and each cell is made up of a positive electrode (cathode), a negative electrode (anode), an electrolyte, and a separator. The most commonly used materials for these components are lithium, cobalt, nickel, and graphite.

These materials are chosen because they are highly conductive and have the ability to hold a large amount of energy. However, the production of these materials can also have an impact on the environment and human health, so it’s important for manufacturers to consider sustainable sourcing and recycling options. Additionally, new materials are constantly being researched and developed to improve the efficiency and sustainability of electric car batteries.

Chemistry Behind the Electrodes

When it comes to the production of electric car batteries, the chemistry behind the electrodes plays a vital role. The electrodes are responsible for facilitating the process of converting chemical energy to electrical energy. Lithium-ion batteries are commonly used in electric cars due to their high energy density, durability, and low maintenance requirements.

The electrodes of these batteries consist of a cathode and an anode, both made up of different materials and elements, which react with the lithium ions in the electrolyte to create a flow of electrons. The cathode typically contains lithium transition metal oxides, while the anode comprises graphite or silicon-based materials. Manufacturers must carefully select and mix these materials to ensure optimal performance and safety.

During the production process, the electrodes are coated with a thin layer of a binder and a conductive substance to enhance performance and durability. Understanding the chemistry behind electric car battery electrodes is necessary to produce high-quality batteries that meet the increasing demand for sustainable transportation solutions.

Battery Manufacturing Process

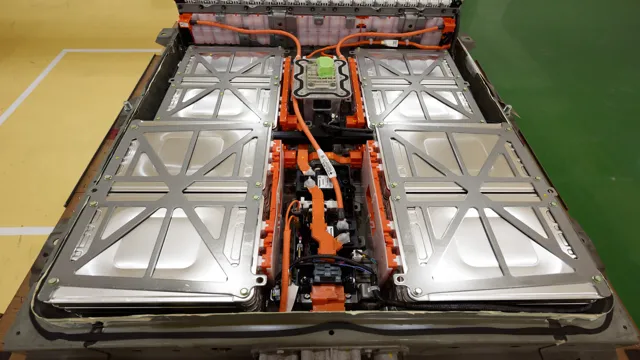

The manufacturing process of electric car batteries is a complex and fascinating one. The process starts with the selection of the right ingredients for battery production, including lithium, cobalt, nickel, and aluminum. These raw materials are then processed in different ways to form anode and cathode materials.

After that, the anode and cathode materials are assembled into battery cells using advanced machinery. The cells are then tested rigorously to ensure their quality and performance. Finally, the cells are assembled into battery packs that can power an electric car.

It’s like cooking a meal, where each ingredient needs to be carefully selected and prepared to create a delicious dish. But instead of a dish, we get an efficient and reliable source of energy that can reduce our dependence on fossil fuels and help pave the way for a more sustainable future.

Challenges Faced by Electric Car Battery Makers

Electric car battery making is a complex process that involves several challenges. One of the biggest challenges is the cost of battery manufacturing. Electric vehicle batteries are expensive to produce because they require high-quality materials and processes to ensure they meet the safety and performance standards.

The other challenge is the longevity and reliability of the batteries. Although electric car batteries are designed to last for years, frequent charging, and extreme temperatures can cause them to degrade over time. As a result, car battery makers are constantly working to improve their manufacturing processes to make the batteries more reliable and affordable.

Despite the challenges, electric car battery makers remain committed to advancing the technology to help reduce the dependence on fossil fuels and fight climate change.

Lack of Raw Materials

Electric car battery makers face numerous challenges, and one of the biggest ones is the lack of raw materials. The production of electric car batteries requires a substantial amount of raw materials such as cobalt, nickel, and lithium. However, these materials are finite resources and are becoming increasingly scarce.

This scarcity has led to price hikes and supply chain disruptions, making it difficult for battery manufacturers to meet the growing demand for electric vehicles. Additionally, the environmental and ethical concerns surrounding the mining of these materials make it more challenging for manufacturers to source them. While efforts are being made to develop more sustainable and ethical mining practices, it will take time to implement them.

Therefore, electric car battery makers must navigate this challenging environment and find ways to secure a sustainable and reliable supply of raw materials to continue producing high-quality batteries for electric vehicles.

Environmental Regulations

Electric car battery makers are facing numerous challenges when it comes to environmental regulations. The production of electric car batteries requires the mining of rare earth metals and minerals, which can have a significant impact on the environment. Battery makers are being tasked with reducing their carbon footprint and ensuring that their manufacturing processes are environmentally friendly.

In addition, there are growing concerns about the disposal of electric car batteries, which contain toxic materials that can harm the environment and human health. Despite these challenges, many battery makers are rising to the occasion and exploring innovative solutions to make their products more sustainable. With the help of advanced technologies and a strong commitment to environmental responsibility, the electric car battery industry has the potential to lead the way in creating a cleaner, healthier world that benefits us all.

Innovations in Electric Car Battery Making

Electric car battery making is an ever-evolving technology. Innovations in battery making are bringing new possibilities, comfort, and safety to electric vehicles. The latest trend is the move towards solid-state batteries.

Compared to current lithium-ion batteries, solid-state batteries have the potential to increase energy density, reduce weight, and overcome risks of overheating. A few automakers have already set a deadline of implementing solid-state batteries by 202 Another innovation is the improved anode materials, such as silicon and metal.

Silicon can increase the capacity of lithium-ion batteries by up to ten times, while metal anodes can increase it by up to 70%. Furthermore, recently, researchers have developed a technique called the atomic layer deposition, which enables higher energy density and a faster charging rate. With these innovations, the future of electric vehicle batteries looks bright.

Solid State Batteries

Solid state batteries are one of the most exciting innovations in the realm of electric car battery making today. These batteries differ from traditional lithium-ion batteries in that they use solid electrolytes instead of liquid ones. This allows solid state batteries to store more energy and charge more quickly than their liquid counterparts.

What’s more, these batteries are also safer since they are less likely to overheat and catch fire. While solid state batteries are still expensive to produce, research and development in this field are rapidly advancing. Companies like Toyota and BMW have already announced their plans to incorporate solid state batteries into their electric vehicles in the near future.

The potential benefits of this technology are enormous including longer driving ranges and faster charging times, which would make owning an electric car more feasible for many consumers.

Battery Recycling Solutions

Battery recycling is a crucial aspect of the electric car industry. As electric cars gain popularity, the demand for batteries only increases. However, these batteries contain hazardous materials that can have negative effects on the environment if not disposed of properly.

Thankfully, there have been major advancements in battery recycling solutions. Companies such as Tesla and Panasonic have invested heavily in research and technology to create closed-loop recycling systems. This means that the materials used in their batteries are recycled and reused to create new batteries, reducing waste.

Additionally, other companies are exploring alternative ways to recycle batteries such as using bacteria to break down the hazardous materials. These innovations not only reduce the negative impact on the environment, but they also make electric cars more sustainable and cost-effective in the long run. By investing in battery recycling solutions, the electric car industry is taking a positive step towards a greener future.

Conclusion

In conclusion, electric car battery making is like baking a cake. It requires the right ingredients, precise measurements, and a whole lot of energy. But instead of flour, sugar, and butter, we use lithium-ion cells, conductive electrolytes, and cathode and anode materials.

The end result is a battery that can power a vehicle for miles, with zero emissions and a reduced dependence on fossil fuels. So the next time you see an electric car on the road, remember that it’s not just a vehicle, but a deliciously sustainable and electrifying creation!”

FAQs

What materials are used to make electric car batteries?

Electric car batteries are typically made up of a combination of lithium, cobalt, nickel, manganese, and graphite.

How long does it take to manufacture an electric car battery?

Depending on the manufacturer, it can take anywhere from a few hours to a few days to manufacture an electric car battery.

What is the lifespan of an electric car battery?

The average lifespan of an electric car battery is about 8-10 years, but this can vary depending on factors such as driving habits, climate, and maintenance.

Can electric car batteries be recycled?

Yes, electric car batteries can be recycled. The materials can be repurposed for new batteries or other products, helping to reduce waste and conserve resources.