Battery Blues: Navigating the Electric Car Material Shortage Crisis

Have you ever wondered about the inner workings of your electric car battery? It’s a fascinating topic, but unfortunately, there’s a bit of a crisis brewing in the world of electric car manufacturing. The global supply chain is currently experiencing a shortage of materials used to make electric car batteries, and it’s causing quite a stir. This shortage has caused some automakers to scramble to secure the necessary materials, while others have postponed production altogether.

With the growing demand for electric vehicles, it’s crucial to address the issue of this material shortage, but first, let’s take a deeper dive into the mechanics of an electric car battery.

Introduction

Have you heard about the electric car battery material shortage that’s been causing a stir in the automotive industry lately? With the rapid growth in demand for electric vehicles, the industry is now facing a significant supply chain challenge. The battery is the most crucial and expensive part of an electric car, and it’s made from materials such as cobalt, lithium, and nickel. Unfortunately, the availability of these materials is currently limited, which has resulted in an increase in their prices.

Many automakers are concerned that this shortage could slow down the production of electric vehicles, disrupt supply chains, and lead to a potential price rise for consumers. However, the industry remains optimistic that innovation and alternative materials can be found to solve the electric car battery material shortage challenges.

Explaining the problem

The problem we will be addressing in this blog post concerns the widespread issue of plastic pollution and its effects on our planet. With the exponential increase in production and consumption of plastics globally, it’s no surprise that our planet is suffering due to the amount of waste that is generated and ends up in our oceans and landfills. This issue is further exacerbated by the fact that plastic can take up to hundreds of years to decompose, leading to significant environmental damage.

As a result, different initiatives and campaigns have emerged worldwide to encourage individuals and companies to reduce their plastic use and dispose of waste responsibly. In this post, we’ll dive deeper into the dimensions of this problem, its environmental impact, and discuss possible solutions to tackle it.

Current state of the electric car battery market

The electric car battery market is a rapidly growing industry that has seen a surge in demand in recent years. As the world becomes increasingly environmentally conscious, the need for sustainable transportation options has become more urgent. As a result, electric vehicles have become more popular, paving the way for the development of more efficient batteries.

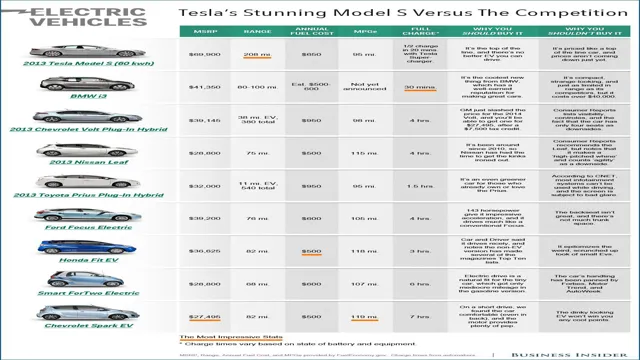

The current state of the electric car battery market is characterized by intense competition among battery manufacturers. Companies like Tesla, Panasonic, LG Chem, and CATL are all vying for a larger market share and are investing heavily in research and development to improve battery performance. The use of sustainable materials and improved manufacturing processes have made electric car batteries more affordable, increasing their accessibility to consumers.

The market is expected to continue its growth trajectory, as more automakers shift their production lines towards EVs. As the industry grows, the pressure to innovate and develop more efficient batteries will only intensify, driving new breakthroughs in the field.

Causes of the Shortage

One of the primary reasons for the electric car battery material shortage is the surge in demand for electric vehicles. As more and more people turn to eco-friendly transportation options, the need for lithium-ion batteries has skyrocketed. However, battery production cannot keep up with the sudden demand increase, leading to a shortage of the materials required to make these batteries.

Additionally, the COVID-19 pandemic has disrupted supply chains and caused delays in the production and transportation of battery materials. The shortage of specific minerals like cobalt and lithium, which are essential to battery production, has also contributed to the problem. All of these factors have come together to create a perfect storm of high demand and low supply, resulting in a shortage of electric car battery materials.

Until these issues are resolved, the electric car industry will continue to struggle to meet the demands of consumers.

Increasing demand for electric cars

As the world shifts toward a more sustainable future, electric cars have become increasingly popular. However, this surge in demand has also brought about a shortage of electric car components, particularly batteries. One of the main causes of this shortage is the complexity of producing high-quality batteries.

These batteries require rare metals, such as cobalt and lithium, which are difficult to mine and process. Another factor is the high demand for battery components, which has created a bottleneck in the supply chain. To make matters worse, supply chain disruptions caused by the COVID-19 pandemic have also slowed down production and delivery of these components.

These factors together have created a perfect storm, leading to a shortage of key components for electric cars. However, despite the challenges, many experts believe that the industry will overcome these obstacles and continue to thrive in the future.

Limited supply of raw materials

The limited supply of raw materials is a significant concern for many industries and companies these days. There are several reasons behind this problem, but one of the primary factors is the rapid increase in demand for raw materials used in various products. The rise of technology and globalization has led to an unprecedented level of demand for many natural resources.

Unfortunately, the supply of some critical raw materials cannot keep up with the growing demand. Additionally, the increasing population means there are more people consuming these materials every day. Another issue is the lack of investment in finding and developing new sources of raw materials.

This lack of investment creates a situation where current sources become scarce, and prices go up. All these factors combined contribute to the limited supply of raw materials that we face today. In summary, the shortage of raw materials is a complex issue with several causes, but it is a problem that needs to be addressed sooner than later to ensure sustainable growth and development.

Impact of the Shortage

The shortage of electric car battery materials is having a significant impact on the industry. As demand for electric vehicles continues to rise, the supply of materials such as lithium and cobalt simply cannot keep up. This has caused delays in production and increased prices for electric car batteries, making them less accessible for the average consumer.

However, this shortage has also spurred innovation in the industry, with companies exploring alternative materials and new battery technologies that may reduce the reliance on these scarce materials. The entire electric car industry is closely watching this situation, as the shortage could potentially slow down the momentum of the electric vehicle market. Nevertheless, experts are hopeful that the industry will continue to adapt and overcome this challenge, paving the way for a greener, more sustainable future.

Delayed production and delivery times for electric vehicles

As the demand for electric vehicles (EVs) continues to surge, the global supply chain is facing a severe shortage of critical components, causing delays in production and delivery times. The pandemic-induced shortage of semiconductor chips, which are vital for the functioning of electric vehicles, has led to a backlog in manufacturing, and a subsequent rise in prices. This has caused car manufacturers to cut back on production, leading to a decrease in the availability of EVs in the market.

The impact of this shortage has been felt worldwide, with many consumers left waiting for long durations to get their hands on their dream electric vehicle. As the industry works to resolve this issue, it is clear that the shortage has severely disrupted the EV market and is likely to remain a challenge for some time to come.

Rising prices of electric car batteries

The rising prices of electric car batteries have been a topic of concern for many people interested in the industry. What’s worse is that there have been shortages of these batteries, which has further exacerbated the issue. With more people interested in electric cars, demand for these batteries has shot up, leading to the current situation.

The impact of the shortage has been felt across the industry, with manufacturers having to adjust their prices accordingly. As a result, consumers are now paying more for electric vehicles than they would have a few years ago. While the prices are still relatively high, it’s essential to consider the long-term benefits of owning an electric car.

More and more people are becoming aware of the sustainability factor, which is why the demand for electric cars is expected to increase in the coming years. As the industry continues to evolve, we can expect prices to stabilise, making electric vehicles more accessible to a broader audience.

Possible Solutions

While the current electric car battery material shortage is a significant concern for the EV industry, there are several possible solutions being explored. One option is to increase recycling efforts of existing batteries to reuse valuable materials such as cobalt and lithium. Another promising option is to invest in research and development to find alternative materials for batteries, such as sodium-ion or solid-state batteries.

Additionally, manufacturers may consider implementing more efficient designs in battery production and reducing dependency on a single source for materials. Although the shortage is daunting, it is spurring innovation and driving advancements in battery technology, which could ultimately lead to a more sustainable and reliable future for electric vehicles.

Exploring alternatives to the raw materials in question

One potential solution to the issues surrounding the raw materials in question is to explore alternatives. By seeking out different types of materials, we may be able to find options that are more sustainable, less harmful to the environment, and more readily available. For example, some companies have begun experimenting with using natural fibers like bamboo and hemp instead of traditional cotton.

Others have turned to recycled materials or even materials made from agricultural waste products. While these alternatives may require some additional research and development to perfect, they could ultimately provide a more viable and environmentally friendly path forward for the industries currently relying on the raw materials in question. With a little creativity and innovation, we may be able to find solutions that benefit both the economy and the planet.

Investing in domestic mining and production

One possible solution to reduce our dependence on foreign minerals is investing in domestic mining and production. By increasing our own production, we’ll be able to decrease the need to import minerals and other materials from other countries. This will not only create more jobs for our citizens, but also help keep the money within our economy.

However, increasing our domestic production won’t be an easy task. There are several challenges we need to overcome, such as environmental concerns and cost-effectiveness. Furthermore, we must ensure that the mining and production are conducted safely and sustainably.

Nonetheless, investing in domestic mining and production could be a key part of our plan to reduce our reliance on foreign minerals.

Conclusion

In conclusion, the search for alternative materials to power electric cars continues to be a bumpy road. As demand for these cars rises, shortages in essential battery materials, such as lithium, cobalt, and nickel, persist. While scientists and manufacturers are working tirelessly to find new and sustainable solutions, it is clear that our reliance on finite resources may slow down the transition to a fully electric future.

Until then, let’s hope that innovation sparks a brighter and more sustainable path forward for the electric car industry. After all, the race to cleaner and greener transportation must continue, no matter the obstacles.

The future of the electric car battery market

As the electric car market continues to grow, the demand for high-quality batteries is increasing at an exponential rate. One possible solution for the future of the electric car battery market is the development of solid-state batteries. These batteries offer several advantages over traditional lithium-ion batteries, including higher energy density, longer lifespan, and improved safety.

While solid-state batteries are still in the early stages of development, they have the potential to revolutionize the electric car industry and provide a more sustainable and efficient source of energy for transportation. Another possible solution is the use of recycled batteries. Rather than disposing of used batteries, they can be repurposed and have their materials extracted and used in the production of new batteries.

This approach would be environmentally friendly and could significantly reduce the cost of production for electric car batteries. Overall, the future of the electric car battery market looks bright, and with continued innovation and development, we can look forward to a world powered by sustainable and efficient energy sources.

Possible outcomes of the material shortage

When faced with a material shortage, there are always possible solutions to explore. One potential solution is to find alternative materials to use in the manufacturing process. This may require some creativity and research, but it can ultimately lead to new and innovative products.

Another option is to reevaluate the manufacturing process and find ways to reduce the amount of material used. This could involve finding more efficient production methods or implementing recycling programs to reduce waste. Additionally, companies can communicate with their suppliers to find out if there are any issues causing the material shortage and work together to find a solution.

By exploring these and other options, companies can help mitigate the impact of a material shortage and continue to meet the demands of their customers. It’s important to remember that every problem can be an opportunity for growth and innovation – even a material shortage.

FAQs

What is causing the electric car battery material shortage?

The increasing demand for electric vehicles, specifically lithium-ion batteries, has created a shortage of the materials needed to produce them such as lithium, cobalt, and nickel.

How is the shortage of electric car battery materials affecting the automotive industry?

The shortage of electric car battery materials is affecting the automotive industry by causing production delays and higher costs for electric vehicle manufacturers.

Are there any alternatives to the current electric car battery materials?

Researchers are exploring alternatives to the current electric car battery materials such as sodium-ion and solid-state batteries, but they are still in the early stages of development and not yet widely available.

What can consumers do to help alleviate the electric car battery material shortage?

Consumers can help alleviate the electric car battery material shortage by considering purchasing a used electric vehicle, carpooling, or using public transportation when possible to reduce demand for new electric vehicles.