Revolutionizing the Automotive Industry: A Complete Guide to Electric Car Battery Manufacturing

Electric vehicles are quickly becoming the future of transportation as more and more consumers switch from traditional gasoline-powered cars to eco-friendly electric vehicles. As the demand for electric cars continues to rise, so too does the demand for their essential component: batteries. This has led to a surge in the manufacturing of electric car batteries as companies around the world compete to produce high-quality, long-lasting batteries that will drive the growth of the electric vehicle industry forward.

In this blog, we’ll take a closer look at the rise of electric car battery manufacturing and how it is shaping the future of transportation. We’ll explore the latest battery technologies, the key players in the industry, and the challenges that lie ahead as we work towards a more sustainable and energy-efficient future. So join us as we dive into the exciting world of electric car battery manufacturing and discover the innovative solutions that are powering the future of transportation.

Market Overview

The electric car battery manufacturing industry has been rapidly growing in recent years, with major companies like Tesla, Panasonic, and LG Chem dominating the market. Due to increasing demand for electric vehicles, battery manufacturers are facing immense pressure to improve their production capacities and efficiency while reducing costs. This challenge has resulted in major technological advancements in the field, including the development of new materials and production methods to improve battery performance and lifespan.

While the industry is currently dominated by a few key players, there is significant potential for smaller companies to enter the market with innovative technologies and disruptive business models. As the world continues to shift towards electric mobility, the electric car battery manufacturing industry is expected to play an increasingly important role in shaping the future of transportation.

Demand for Electric Cars

The demand for electric cars has been on the rise in recent years due to several factors. One primary driver of this trend is the growing awareness of environmental concerns and the need to reduce carbon emissions. Electric cars emit significantly less CO2 compared to traditional gasoline-powered vehicles, making them more eco-friendly.

Additionally, advancements in battery technology have improved the range and speed of electric vehicles, making them a more practical option for daily use. As a result, more and more consumers are choosing to make the switch to electric cars. In fact, the electric car market is expected to see a growth rate of over 30% annually over the next few years.

This presents a significant opportunity for automakers to develop and sell more electric cars to meet the increasing demand in the market. Overall, the demand for electric cars is anticipated to continue rising in the coming years, creating a promising future for the electric car industry.

Global Battery Production

Global battery production has been on the rise in recent years, driven by the increasing demand for electric vehicles and renewable energy storage systems. According to a report by Bloomberg New Energy Finance, the global battery market is expected to grow at a rapid pace, reaching $116 billion by 2030. Major players in the market include Tesla, Samsung, LG Chem, and Panasonic, among others.

The shift towards clean energy and the need for energy storage systems has created an opportunity for battery manufacturers to invest in research and development, leading to improved battery technologies with longer lifetimes and higher energy densities. However, challenges such as supply chain disruptions, raw material shortages, and safety concerns still need to be addressed. Despite these challenges, the future looks bright for the battery industry as it continues to innovate and drive the transition towards a cleaner, more sustainable future.

Major Players in the Industry

As the demand for technology and automation rises, the industrial sector has become a hotbed for competition and innovation. The market is dominated by several major players, each with unique strengths and specialties. Among these giants are Siemens, General Electric, Schneider Electric, ABB, and Honeywell.

Siemens is known for its state-of-the-art automation systems and energy-efficient solutions. General Electric is a pioneer in digital transformation, offering software and software-based services to optimize performance and productivity. Schneider Electric provides a range of services, from developing hardware-based solutions to managing smart buildings and cities.

ABB is a leader in power and automation technologies, offering advanced robotics and control systems. Finally, Honeywell specializes in developing highly efficient systems for commercial, industrial, and residential markets. Each of these companies offers significant value to the industry, and they continue to innovate and push boundary lines to meet the demands of the market.

As technology advances and new trends emerge, these major players in the industry will continue to set the standards for innovation, efficiency, and productivity.

Battery Manufacturing Process

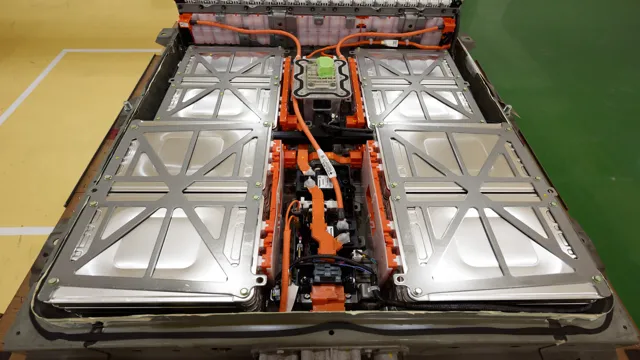

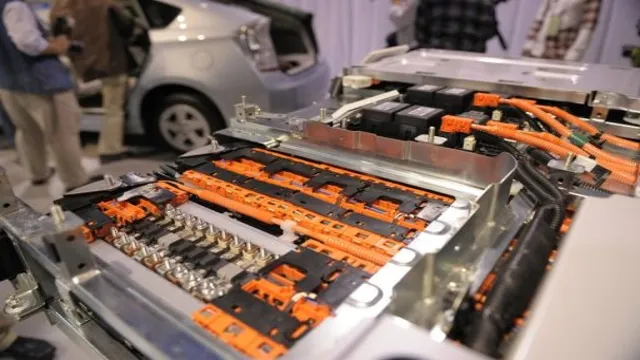

When it comes to manufacturing an electric car battery, there are a few key components that are required. Firstly, the cathode, anode, and electrolyte materials are all combined to create the battery cell. This is then packaged in a metal case and sealed with a cap.

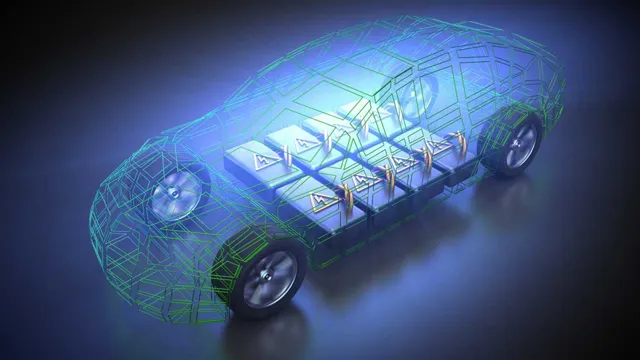

The process of creating these components involves a series of chemical reactions and precision measurements to ensure that the battery produces the desired voltage and power output. Once the battery cells are created, they are assembled into battery packs, which can be configured in various ways to suit different vehicle designs. These battery packs are then rigorously tested to ensure that they meet safety and performance standards before being installed in electric vehicles.

Overall, the process of manufacturing electric car batteries is complex and requires a high level of expertise in both chemistry and engineering. However, the end result is a highly efficient and environmentally friendly power source that is helping to revolutionize the automotive industry.

Raw Materials

One of the most important raw materials in the battery manufacturing process is lithium. Lithium is a silvery-white metal that is extremely light and highly reactive, making it an ideal material for use in batteries. Lithium-ion batteries, in particular, are used in a wide range of applications, including smartphone and laptop batteries, electric vehicles, and renewable energy storage systems.

In addition to lithium, other raw materials commonly used in battery manufacturing include nickel, cobalt, copper, graphite, and aluminum. These materials are used to create the electrodes, electrolytes, and casing that make up the battery. Ensuring an adequate supply of these raw materials is a crucial aspect of battery manufacturing, which is why many companies are actively working to develop new sources and methods of production that are more sustainable and environmentally friendly.

Overall, the battery manufacturing process is a complex and highly technical process that requires careful attention to detail and quality control at every stage of production.

Cell Production

The battery manufacturing process, also known as cell production, is a complex and intricate process that requires precision and careful attention to detail. It all begins with the selection of the raw materials that will be used to create the various components of the battery. These materials are chosen based on their ability to conduct electricity and their durability.

Once the raw materials are selected, they are mixed together to form a paste, which is then coated onto metal foil to create electrodes. These electrodes are then assembled with a separator and electrolyte to form a cell. The cells are then packaged and tested to ensure they meet quality standards before being shipped to manufacturers for use in various products.

The entire battery manufacturing process is highly regulated to ensure the safety and quality of the finished product. With the ever-increasing demand for batteries, manufacturers are constantly looking for ways to improve the process to create more efficient and sustainable batteries.

Assembly and Testing

The battery manufacturing process involves several crucial steps that ensure the final product is of high quality and reliability. The first step in the manufacturing process is assembly, where the various battery components come together to form a complete unit. During the assembly process, great care is taken to ensure that each component fits perfectly, and no defects are present.

This step is critical as any errors during assembly can lead to performance issues or even reduce the battery’s lifespan. After assembly, the battery undergoes several tests that verify its capacity and safety. These tests are essential to ensure that the battery meets the required regulatory standards and is safe for use.

Once the testing is complete, the battery is ready for packaging and shipping to its intended market. In conclusion, the battery manufacturing process involves many intricate steps that require strict adherence to quality and safety standards. A well-made battery is critical for various industries, and the manufacturing process ensures that only the best products make it to the market.

The keyword used organically throughout the paragraph is “battery manufacturing process.”

Challenges and Innovations

The production of electric car batteries has become an increasingly important aspect of the automotive industry, with more and more car manufacturers aiming to shift towards electric vehicles. However, there are still numerous challenges surrounding the manufacturing of these batteries, including the cost of raw materials, the environmental impact of mining these materials, and the issue of battery waste disposal. To combat these challenges, innovators in the field are exploring new techniques and technologies in battery production to create more sustainable and efficient batteries.

For instance, researchers are looking at alternative materials, such as sodium-ion, to replace costly and finite resources like cobalt and lithium. Additionally, battery recycling is becoming more widespread, allowing for more efficient use of materials and reducing waste. As electric car demand continues to grow, manufacturers must rise to the challenge of producing these batteries sustainably and efficiently, while also maintaining affordability for consumers.

Environmental Impact

When it comes to the environmental impact of modern industry, there are a number of challenges that we need to address. One of the biggest issues is carbon emissions, which contribute significantly to climate change. In recent years, a number of innovations have emerged that seek to tackle this problem, including renewable energy sources like wind, solar, and hydroelectric power.

These technologies have improved significantly in recent years, and are becoming more and more viable as alternatives to fossil fuels. In addition to renewable energy, there are also a number of other exciting innovations being developed, such as carbon capture and storage technologies that could help to mitigate the impact of carbon emissions. While there is still a long way to go when it comes to reducing the environmental impact of modern industry, these innovations provide a glimmer of hope that we can move towards a more sustainable future.

Cost Reduction Strategies

Cost reduction strategies can be challenging to implement, especially in today’s fast-paced and ever-changing business environment. One of the biggest challenges is finding the right balance between cost reduction and maintaining the quality of products or services. To achieve this, businesses can adopt innovative strategies such as lean management, outsourcing, and automation.

Lean management involves optimizing processes to reduce waste and increase efficiency. Outsourcing can help businesses cut costs by delegating non-core activities to third-party service providers. Automation can reduce labor costs and enhance productivity by automating repetitive tasks.

While these strategies can be effective, they require careful planning and execution to ensure their success. Overall, businesses need to be adaptable and willing to embrace new innovations to stay competitive and reduce costs without sacrificing quality.

Future of Electric Car Battery Manufacturing

The future of electric car battery manufacturing appears bright, as demand for electric vehicles continues to rise. Battery technology is one of the key factors in making EVs a viable option for the masses, and research and development in this area is progressing rapidly. Companies are working to create batteries with longer lifespans, faster charging times, and increased energy storage capabilities.

Additionally, efforts to reduce the cost of battery manufacturing are underway, which will make EVs more affordable for consumers. The electric car battery manufacturing industry is poised for significant growth in the coming years, and it will be exciting to see the innovations and advancements that emerge. Overall, the future looks promising for electric car battery mfg, and it will be interesting to see how this technology evolves over time.

Conclusion

In conclusion, the electrification of cars is not just a trend, but a fundamental shift towards a more sustainable future. A major factor in this shift is the development of electric car batteries, which have evolved from bulky and inefficient to sleek and powerful. Battery manufacturing has become a vital aspect of the electric car industry and its growth is imperative for a cleaner and greener future.

So let’s charge ahead, with the power of electricity at our fingertips and the goal of a brighter, cleaner tomorrow in our minds.”

FAQs

What is electric car battery manufacturing?

Electric car battery manufacturing involves the production of rechargeable batteries which are used to power electric vehicles.

How are electric car batteries manufactured?

Electric car batteries are manufactured using lithium-ion cells which are assembled into battery packs. These cells are manufactured through complex chemical processes and then tested for quality and performance.

What are the benefits of electric car batteries?

Electric car batteries provide a more environmentally-friendly alternative to traditional gasoline-powered vehicles, as they produce no emissions. They also tend to be more cost-effective to operate and maintain over time.

How long do electric car batteries last?

The lifespan of an electric car battery can vary depending on several factors, including how frequently the vehicle is used, the charging habits of the owner, and the climate in which the vehicle is driven. However, most electric car batteries are designed to last for several years before needing to be replaced.