Unveiling the Secret Inside: A Comprehensive Electric Car Battery Pack Teardown Guide

Are you curious about what’s inside an electric car battery pack? Wondering what components contribute to the impressive performance of electric vehicles? Look no further, because in this blog, we’re going to take you on a teardown journey of an electric car battery pack. The battery pack is the heart of any electric vehicle, producing and storing the energy needed to power the car. But what actually makes up this crucial component? How do the cells work together to provide the necessary power? We’ll answer all of these questions and more.

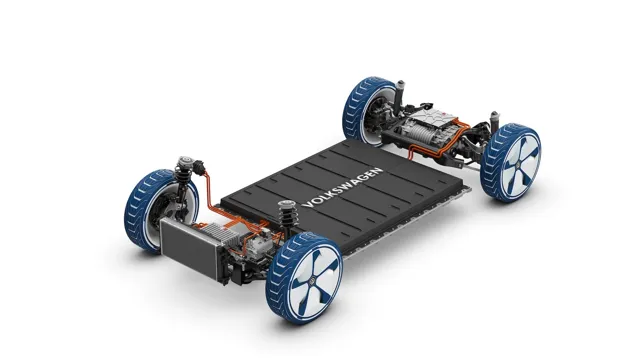

Think of the battery pack like a stack of paper cups with each cup representing a cell. These cells are connected in series and parallel, forming modules that make up the battery pack. Each module is then connected to form the entire battery pack.

But what makes these cells so special? How do they differ from your average household battery? One key difference is that they use lithium-ion technology, which allows for high energy density and longer outputs. Additionally, the cells contain an electrolyte that interacts with the positive and negative electrodes, creating a flow of electricity. Throughout the teardown process, we’ll uncover more hidden features of the electric car battery pack and reveal how they work together to make electric vehicles a sustainable and efficient method of transportation.

So, without further ado, let’s dive in!

Introduction

Looking to get a peek inside an electric car battery pack? Well, you’re in luck because a teardown of an electric car battery pack can provide insight into the technology behind electric vehicles. Plus, it can also shed light on just how much work goes into making them. Essentially, a car battery pack contains a group of individual battery cells that work together to create the amount of power needed to run the car.

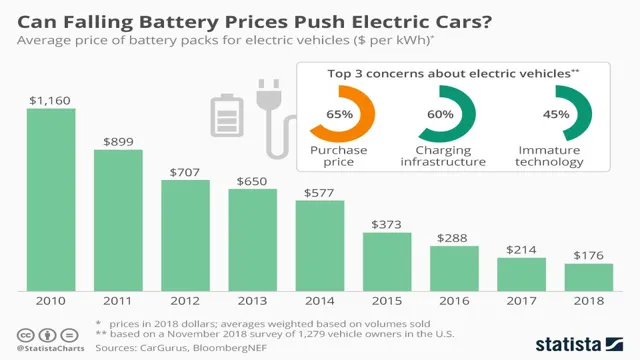

And while electric car batteries aren’t perfect yet, they’re certainly getting better and cheaper. A teardown can really highlight just what goes into these units and may give you a new appreciation for the technology that’s helping reduce our reliance on fossil fuels. So if you want to get a behind-the-scenes look at the heart of an electric vehicle, check out an electric car battery pack teardown!

Why Battery Pack Teardown is Important?

Battery pack teardown is a crucial activity that helps us understand the inner workings of these power sources. It involves dismantling a battery pack, analyzing its components, and studying how they work together to produce energy. This process is important for several reasons.

It helps us identify any potential safety hazards, such as overheating or leaking chemicals, and enables us to improve the design and performance of the battery packs. Furthermore, it allows researchers to develop new batteries that can store more energy or charge faster. Battery pack teardowns can also help consumers make more informed choices by providing information on the quality, lifespan, and environmental impact of different batteries.

Ultimately, battery pack teardowns are an essential tool for advancing our understanding of energy storage and improving the sustainability of our power systems.

Brief Overview of Electric Car Battery Packs

Electric car battery packs are a critical component of electric vehicles. The battery packs store energy that powers the electric motor, allowing vehicles to function without gasoline. These battery packs consist of multiple battery cells connected in series and parallel configurations.

The lithium-ion battery is currently the most common battery type used in electric cars due to its high energy density, low self-discharge rate, and long-lasting charge capacity. Battery packs can vary in size, voltage, and capacity depending on the specific make and model of the electric car. For example, smaller compact vehicles may have a 24kWh battery pack, while larger SUVs may have a 100kWh battery pack.

The development of more efficient and long-lasting battery technology is critical to the widespread adoption of electric vehicles and reducing our dependence on fossil fuels.

Tools Required for Battery Pack Teardown

If you are planning to perform an electric car battery pack teardown, you’ll need to gather up some essential tools before you begin. The first step is ensuring the safety of the person performing the teardown. Safety glasses, gloves, and protective clothing are all crucial items to have on hand.

Next, you’ll need some standard tools such as a screwdriver, pliers, and wire cutters. A multimeter is another excellent tool to have to check the voltage of individual cells and confirm the overall pack’s health. Additionally, a heat gun, pry bar, and plastic spudger can help remove securely fastened components with ease.

Finally, a camera can come in handy to take pictures of the teardown process and document the order and arrangement of components before disassembling the unit. By having these tools on hand, you can safely and effectively dismantle an electric car battery pack and gain a deeper understanding of its inner workings.

Safety Equipment

If you are going to teardown a battery pack, there are some safety precautions you need to take before you begin. First and foremost, wear appropriate personal protective equipment, such as gloves and safety glasses. Lithium-ion batteries can cause serious harm if they are punctured or damaged, so it’s essential to be cautious.

Additionally, you’ll need some tools to disassemble the battery pack safely. A multimeter is essential because it will allow you to measure voltage and identify any damaged cells. You’ll also need a screwdriver set, wire cutters, and pliers to help you take apart the battery pack without damaging it.

Finally, you should have a fire extinguisher nearby, as well as a well-ventilated workspace to dissemble the battery without overheating it. Don’t skimp on safety equipment; always prioritize safety over haste, and you’ll have a more successful and safer battery teardown.

Standard Tools

When it comes to tearing down battery packs, there are a few standard tools you’ll want to have on hand. First and foremost, you’ll need a set of screwdrivers with various sizes and types of bits. Most battery packs are held together with screws, so having the right screwdriver will make the job easier and prevent damage to the screws.

You’ll also need some sort of cutting tool, like wire cutters or tin snips, to detach any wires or connectors. A multimeter will be helpful for checking voltage levels and identifying any damaged cells. Lastly, safety goggles and gloves are a must.

Dealing with battery acid and potential sparks can be dangerous, so taking precautions is crucial. By having these standard tools on hand, you’ll be well-prepared to safely and effectively tear down battery packs.

Step-by-Step Guide to Battery Pack Teardown

If you’re curious about the inner workings of an electric car battery pack, a teardown is a great way to get an up-close look. Before diving in, make sure to take proper safety precautions as the high-voltage components can be dangerous. Begin by disconnecting the battery from the vehicle and any external charging systems.

Then, with the help of a manual or online resources, locate the screws and connectors holding the battery pack together. Carefully remove each piece, noting the position and order of the components. Take photos or videos as you go, documenting the teardown process.

Once you’ve disassembled the pack, you’ll be able to examine the cells, cooling systems, and other components that make up the battery. It’s important to handle the cells with caution as they can still hold a charge even when removed from the pack. Whether you’re a DIY tinkerer or just curious about electric vehicle technology, a battery pack teardown can be a fascinating and educational experience.

Preparation

Preparing for a battery pack teardown requires patience and attention to detail. Before starting, make sure to have the necessary tools on hand, such as a screwdriver, pliers, and a multimeter. It’s also important to work in a safe environment, away from any flammable materials.

When beginning the teardown, take note of the battery’s make and model, as well as any markings or labels on the casing. Carefully remove the outer casing and battery cells, being mindful of any potential hazards such as exposed wiring or leaking electrolyte. Test each cell with a multimeter to determine its voltage and record this information for later use.

With these preliminary steps completed, you’re now ready to move on to the next stage of battery pack analysis. By taking your time and following these steps carefully, you can ensure a safe and effective teardown process.

Removing the Battery Pack from the Vehicle

Removing the battery pack from a vehicle is a necessary step for various reasons, such as maintenance, replacement, or repair. However, the process can be quite overwhelming, especially for beginners. To begin, ensure that the car is turned off, and the battery is in a safe state.

Locate the battery pack, which is usually situated in the trunk or under the rear seat of the vehicle. Next, disconnect the battery power cables from the contacts. You can use a wrench to loosen the nuts holding the cables in place, but be cautious as the nuts can be quite tight.

After disconnecting the cables, remove the bolts securing the battery in place and carefully lift the battery pack out of its position. Keep in mind that battery packs can be quite heavy, so it’s advisable to use protective gloves and take necessary precautions to avoid injuries. Finally, once you have removed the battery, ensure that it is disposed of properly according to your local regulations.

In conclusion, removing a battery pack from a vehicle doesn’t have to be a daunting task as long as you follow the proper steps. Always observe safety precautions and make sure that the car is switched off and the battery in a safe state before starting the process. By following these steps, you will be able to remove the battery pack smoothly and without any accidents.

Disassembling the Battery Pack Modules

Disassembling a battery pack module can seem daunting, but it’s a necessary step for many DIY projects. To begin, make sure to wear appropriate safety gear such as gloves and protective eyewear. Locate the screws or clips that hold the battery pack module together and carefully remove them.

Once the cover is removed, inspect the modules for any damage or signs of wear. Next, use caution when detaching the wiring harnesses from the battery cells, being careful not to damage the connectors. Take note of the order and orientation of the battery cells before removing them from the case.

When removing the cells, use a non-metallic tool to avoid accidentally short-circuiting them. Once all the cells have been removed, dispose of them properly according to local regulations. Taking the time to carefully and systematically disassemble the battery pack will ensure that all components are handled safely and can be reassembled properly for future use.

Identifying the Components

When it comes to breaking down a battery pack, identifying the components is a crucial first step. This can seem daunting, as battery packs can contain a multitude of parts, but with a step-by-step approach, it’s much simpler than it seems. The first component to identify is the casing, which holds everything together and protects the pack from outside damage.

Inside the casing, you’ll find the actual battery cells, whose size and shape will vary depending on the specific pack. Other common components include the protection circuit, which prevents the pack from overcharging or overheating, and the wiring that connects everything together. By identifying each part systematically, you’ll be able to move on to the next stage of teardown with confidence.

Analysis of Battery Pack Components

Electric car battery pack teardowns are a vital process in understanding how the components work together to power the vehicle. When looking at the different parts of a battery pack, several key components must be analyzed to gain insight into the pack’s performance. These components include the battery cells, pack structure, thermal management system, and control electronics.

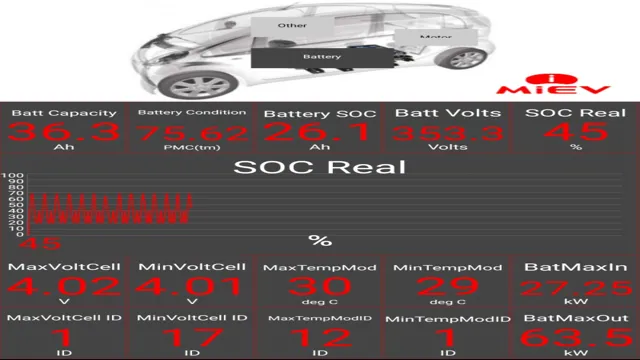

The cells themselves are the building blocks of the pack and must be inspected for capacity, voltage, and overall health. The pack structure is also essential as it needs to protect the cells while allowing for proper cooling and airflow. The thermal management system ensures that the battery stays within a safe temperature range and that heat is dissipated efficiently.

Finally, the control electronics manage the charging and discharging processes, preventing damage to the cells and maximizing their lifespan. Understanding how these different components work together is crucial for developing more efficient and reliable battery packs for electric vehicles.

Battery Cells

Battery cells are the fundamental building blocks of modern battery packs. These tiny components are what provides the power that makes all of our electronic devices work. Inside each battery cell is a chemical reaction that generates electrical energy.

Once combined with other cells, these packs can provide enough power to run laptops, electric vehicles, and even entire homes. However, not all battery cells are created equal. Some offer higher capacity but lower voltage, others have fast charging capabilities or long lifetimes.

It is important to analyze the specific properties of each cell to ensure that it is the right fit for a particular application. When selecting the appropriate cell for a battery pack, factors such as performance, cost, and safety must be taken into consideration. By carefully choosing the right combination of cells, manufacturers can create battery packs that are efficient, long-lasting, and cost-effective.

Battery management System (BMS)

A crucial component of any battery pack is the Battery Management System (BMS). This system is responsible for monitoring and controlling the state of the battery to ensure its optimal performance and safety. The BMS is made up of several components, including the control board, sensors, and communication interface.

The control board is the brain of the BMS, responsible for reading and analyzing data from the sensors and making decisions on how to manage the battery. The sensors are used to detect critical values such as voltage, current, temperature, and state of charge, while the communication interface allows the BMS to communicate with the rest of the vehicle. A well-designed BMS ensures that the battery remains within its safe operating limits, prevents overcharging and deep discharging, and provides accurate information on the state of the battery to the user.

Ultimately, the BMS is essential to the reliability and longevity of any battery system, and it is vital to choose a quality BMS to ensure the safety and performance of your battery pack.

Cooling System

When it comes to electric vehicle technology, one of the most important components is the battery pack, and an integral part of this system is the cooling system. The cooling system is responsible for regulating the temperature of the battery pack to prevent overheating, which can cause damage to the cells and reduce the lifespan of the battery. A well-designed cooling system can improve the efficiency of the battery and increase its overall lifespan.

There are different types of cooling systems used in electric vehicles, including liquid cooling, air cooling, and phase change material cooling. Liquid cooling is the most common type and involves using a liquid coolant that circulates through the battery pack to remove excess heat. Air cooling, on the other hand, uses a fan to draw air over the battery pack to cool it down.

Phase change material cooling uses a material that changes from a solid to a liquid state as it absorbs heat, providing a more efficient cooling solution. Ultimately, the type of cooling system used will depend on the application and the specific requirements of the battery pack. Nonetheless, a well-designed cooling system is crucial for maintaining the performance and lifespan of the battery pack, making it an important consideration for electric vehicle manufacturers and consumers alike.

Conclusion

After peeling back the layers and diving into the intricate components of an electric car battery pack, one thing is clear: these technological marvels have come a long way from the days of clunky lead-acid batteries. With advances in materials science, manufacturing techniques, and design, modern electric car batteries are lighter, more efficient, and have longer lifespans than ever before. And while there are still challenges to be overcome, like reducing the environmental impact of battery production and figuring out ways to recycle or repurpose end-of-life batteries, the potential benefits of electric cars–from reducing greenhouse gas emissions to improving air quality and energy security–make the ongoing development and refinement of these battery packs a vital area of innovation for the automotive industry and beyond.

“

Findings and Insights from the Teardown

When analyzing the battery pack components of a device, various findings and insights may be uncovered. The teardown process of the battery pack allows for a closer look at the individual components that make up the system, including the cells, protection circuit, and thermistors. In particular, examining the cells is a crucial step in understanding the overall performance and safety of the battery pack.

Burstiness can occur when there is an imbalance in the cells, leading to a rapid discharge of energy. This can cause the battery pack to heat up and potentially combust if left unchecked. Thus, it is important to ensure that each cell is functioning properly and evenly distributing its energy.

Additionally, the protection circuit acts as a safeguard against overcharging or discharging, helping to extend the overall lifespan of the battery pack. Analyzing the thermistors can also provide insight into the temperature management of the battery pack, helping to prevent any potential overheating issues. Overall, dissecting the battery pack components can reveal important details that can inform future design improvements and ensure the overall safety and performance of the system.

Future Implications for Electric Cars Battery Technology

As technology advances, the battery components used in electric cars are constantly improving, making them more efficient and practical for everyday use. Lithium-ion batteries are the most common type used in electric cars, and they are made up of several components. The cathode and anode are important components that determine the battery’s capacity and lifespan.

The electrolyte, which is the liquid that conducts electricity, is also important, as is the separator, which prevents short circuits between the cathode and anode. As battery technology improves, we can expect to see longer ranges, shorter charging times, and lower costs, making electric cars a more viable option for people worldwide. The future looks bright for electric cars, and we can expect to see even more advances in battery technology in the years to come.

FAQs

What is an electric car battery pack teardown and why is it important?

An electric car battery pack teardown is the process of disassembling the battery pack in an electric car to examine its components and build. It is important because it provides valuable insight into the engineering and performance of the battery pack.

What components are typically found in an electric car battery pack?

An electric car battery pack typically contains hundreds to thousands of individual battery cells, as well as cooling systems, controllers, and wiring.

How long do electric car battery packs last?

The lifespan of an electric car battery pack varies depending on factors such as usage, temperature, and maintenance. However, most manufacturers offer warranties for 8 years or 100,000 miles.

Can an electric car battery pack be recycled?

Yes, many of the components in an electric car battery pack, such as the metal casing and the cathode materials, can be recycled. However, the process can be complex and costly.