Powering the Future: Inside the State-of-the-Art Electric Car Battery Plant

Electric car battery plants are becoming increasingly popular as the demand for electric vehicles rises. With the world striving to reduce carbon emissions and dependence on fossil fuels, electric cars are gaining popularity, and battery plants are a crucial aspect of this transition. These plants are responsible for manufacturing the batteries that power electric cars, and they play a critical role in the industry’s growth.

As more automakers shift their focus towards electric cars, the demand for battery plants is expected to rise significantly. But what makes an electric car battery plant different from a standard car battery plant? And how do these plants affect the environment and the economy? In this blog post, we will explore these questions and provide an in-depth overview of the electric car battery plant industry.

What is an electric car battery plant?

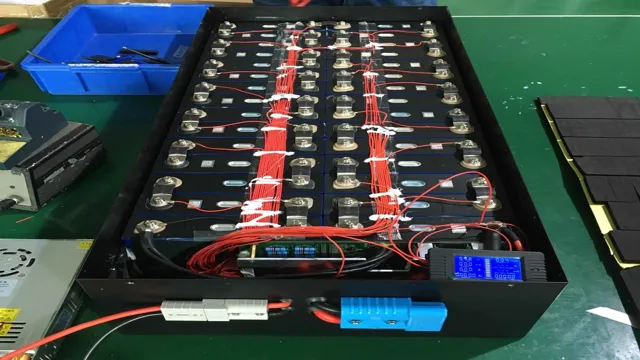

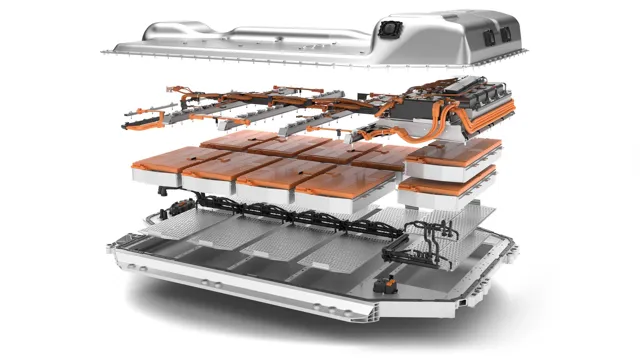

An electric car battery plant is a facility that produces the batteries used in electric vehicles (EVs). These batteries are typically much larger and more powerful than the batteries found in traditional gas-powered vehicles, and they are designed specifically to power an electric motor for extended periods of time. EV batteries are made up of numerous individual cells, each of which contains a cathode, an anode, and an electrolyte solution.

These cells are then typically combined into larger modules, which are in turn combined into the final battery pack. Battery plants often use specialized equipment and processes to ensure that each individual cell is manufactured to exacting specifications, which in turn helps to ensure that the final battery pack performs consistently and reliably over its lifespan. With the growing popularity of EVs, battery plants are becoming an increasingly important part of the automotive industry, and many manufacturers are investing heavily in new battery production facilities.

Defining lithium-ion batteries

Lithium-ion batteries are essential components of most modern technology because of their ability to store a large amount of energy in a small, lightweight package. Electric car batteries are essentially large lithium-ion battery packs that power the vehicle’s electric motor. To produce these batteries in large volumes, specialized plants known as electric car battery plants are necessary.

These facilities are integrated factories that handle everything from cell production to assembly, quality control, and recycling. They often use automated processes to minimize human error and increase efficiency. In these plants, complex machinery and precise engineering come together to produce high-quality lithium-ion batteries that can be used in a range of applications beyond electric vehicles.

Consequently, electric car battery plants become crucial for the development of battery-electric vehicles and other technologies that rely on the high-capacity and safe storage of lithium-ion.

How are electric car batteries made?

An electric car battery plant is a facility that manufactures lithium-ion batteries used in electric vehicles. These batteries are similar to the ones found in smartphones and laptops but are much larger and designed to power a car. The process of making electric car batteries starts with mining for metals such as lithium, cobalt, and nickel.

These metals are then processed and refined into a cathode, anode, electrolyte, and separator. The battery cells are then assembled using robots and undergo a series of tests to ensure they meet quality standards. The final step is to integrate these battery cells into larger battery packs, which are then installed in electric cars.

The demand for electric car batteries is increasing as more people make the shift towards electric vehicles. These batteries are a crucial component of electric cars and have a significant impact on the vehicle’s performance, range, and cost.

Why are electric car battery plants important?

Electric car battery plants are becoming increasingly important as the demand for electric vehicles rises. These plants play a critical role in advancing sustainable transportation by producing the batteries that power electric cars. Without battery plants, it would be challenging to meet the rising demand for electric vehicles, given that this technology is still relatively new and not yet widespread in most countries.

The production of battery cells is the most expensive and challenging part of an electric car’s manufacturing process. One reason for this is the high cost of materials such as lithium and cobalt, which are vital components of most batteries. However, as more battery plants are built, the costs associated with electric vehicles’ production will decrease.

This will result in more affordable electric vehicles and help make sustainable transportation more accessible to everyone. The increase in battery plants’ production will also boost job growth in the energy sector, from construction jobs to highly skilled workers who operate and maintain these facilities. Overall, electric car battery plants are critical to the future of sustainable transportation and will help accelerate the transition from gasoline-powered vehicles to greener alternatives.

Reducing carbon footprints

Reducing carbon footprints / Electric car battery plants As we move towards a more environmentally conscious future, reducing carbon footprints has become a top priority. Electric cars are an important step towards achieving this goal. However, it’s not just about the cars themselves, but also the battery plants that produce the batteries for these cars.

These battery plants are crucial in reducing our carbon footprint because they allow us to rely less on fossil fuels for transportation. By using clean energy sources like wind and solar power, we can power these plants in a more sustainable way. In addition, these plants also create jobs and stimulate the economy, making it a win-win situation for everyone.

So, don’t just focus on the cars when it comes to reducing carbon footprints – consider the importance of electric car battery plants too!

Creating jobs

Electric car battery plants are crucial for creating jobs and providing a sustainable future. These plants are vital for producing electric car batteries, and as the demand for electric vehicles increases, so does the need for battery manufacturing plants. These facilities generate a significant amount of employment opportunities, ranging from engineers and technicians to factory workers.

With a burgeoning electric vehicle market, an electric car battery plant is an ideal solution for creating new jobs and supporting the economy. Furthermore, these plants can help reduce greenhouse gas emissions, leading to a cleaner and greener environment. Just like planting a seed, building electric car battery plants will eventually yield an assortment of growth, with new jobs planting their roots in local communities while also providing an eco-friendly solution to today’s transportation needs.

Promoting renewable energy

As we strive to promote renewable energy, electric car battery plants are becoming increasingly important. Why is that, you might ask? Well, for starters, electric cars are becoming more and more popular as people recognize the need for sustainable transportation. With this increase in demand, we need to ensure that we have the infrastructure in place to produce enough batteries for these vehicles.

Battery plants not only create jobs, but they also help to reduce our reliance on fossil fuels. By converting to electric cars, we can help reduce carbon emissions and create a cleaner environment for future generations. In other words, electric car battery plants are the foundation of a sustainable transportation system.

Where are electric car battery plants located?

As electric cars become more popular, the demand for electric car batteries has skyrocketed. To meet this demand, electric car battery plants have been established all over the world. Some of the biggest electric car battery plants include Tesla’s Gigafactory located in Nevada, LG Chem’s plant in South Korea, and CATL’s plants in China.

These plants are massive facilities capable of producing billions of lithium-ion batteries every year. With the increasing popularity of electric cars, it’s likely that more electric car battery plants will be established in the years to come. The establishment of these plants not only signifies the shift towards greener and more sustainable transportation but also the creation of new jobs and economic growth in the areas they are located in.

Global electric vehicle production centers

Electric car battery plants have become an increasingly important factor in the global electric vehicle (EV) production industry. The majority of EV battery cells are produced in Asia, particularly in China, Japan, and South Korea. China’s dominance in the EV market is reflected in the largest share of battery production capacity.

However, other regions, such as Europe and North America, are catching up with their own battery production plants being established by various companies. For example, Tesla’s Gigafactory is in Nevada, USA, while several European countries, including Germany and Sweden, are building their own battery factories. These global battery production centers show that the EV industry is strongly dependent on battery technology and requires a global supply chain of raw materials, components, production, and recycling.

Top electric car battery plants in the world

Electric car battery plants have become increasingly important in the past few years as the world has become more focused on reducing carbon emissions and shifting toward renewable energy sources. Some of the top electric car battery plants in the world are located in Asia and Europe. The Tesla Gigafactory 1 in Nevada is one of the largest electric car battery plants in the world, producing batteries for Tesla’s electric vehicles.

In China, the CATL (Contemporary Amperex Technology) battery plant in Ningde is another major player in the industry. South Korea is home to LG Chem’s EV battery plant, which produces batteries for car manufacturers like General Motors and Ford. Europe also has a strong presence in the industry, with the Northvolt Factory in Sweden and the Britishvolt plant in the UK.

These plants represent the forefront of electric car battery production and will likely continue to be major players in the industry for years to come.

The Future of Electric Car Battery Plants

Electric car battery plants are becoming increasingly important as the demand for electric vehicles continues to rise. One of the biggest challenges facing the industry is the need for more efficient and cost-effective battery production. This has led to the development of new technologies and processes aimed at increasing production capacity and reducing costs.

Many of these new plants are being built with sustainability in mind, with an emphasis on using renewable energy sources and reducing waste. In the coming years, we can expect to see a significant increase in the number of electric car battery plants around the world, as countries seek to reduce their reliance on fossil fuels and transition to a more sustainable energy future. These plants will play a critical role in helping to meet the growing demand for electric vehicles and pave the way for a greener, more sustainable transportation system.

Conclusion

In conclusion, the electric car battery plant is not just an enabler of sustainable transportation, but a symbol of the world’s commitment towards a greener future. It represents a shift in perspective – one that prioritizes responsible innovation over short-term gains. So the next time you see an electric car whizzing by, remember that it’s not just about convenience or sleekness, it’s about being part of a larger movement towards a cleaner, smarter and more connected world.

Put simply, the electric car battery plant is powering not just vehicles, but progress. “

FAQs

What is an electric car battery plant?

An electric car battery plant is a manufacturing facility that produces high-capacity rechargeable batteries for electric vehicles.

Where are electric car battery plants typically located?

Electric car battery plants are typically located close to major automotive production sites or near areas with abundant renewable energy sources.

How do electric car battery plants impact the environment?

While the manufacturing process itself can have environmental impacts, the use of electric vehicles with these batteries can ultimately have a positive impact on the environment by reducing greenhouse gas emissions.

What is the current global capacity for electric car battery production?

As of 2021, the global capacity for electric car battery production is over 260 gigawatt-hours per year, with most of this capacity located in Asia.