Revolutionizing the Future: India’s First Electric Car Battery Plant Powers Up!

India is quickly emerging as one of the world’s largest electric vehicle markets, with increasing numbers of car manufacturers rolling out EV models tailored to the Indian market. However, a key challenge to the widespread adoption of EVs is the lack of domestic battery production. That may be about to change, with reports indicating that several international companies are considering building electric car battery factories in India.

The arrival of a domestic electric car battery plant would drastically cut India’s dependence on imported batteries, making EVs more affordable and accessible to Indian consumers. This blog will delve into the potential advantages of an electric car battery plant in India.

Growing Demand for Electric Vehicles

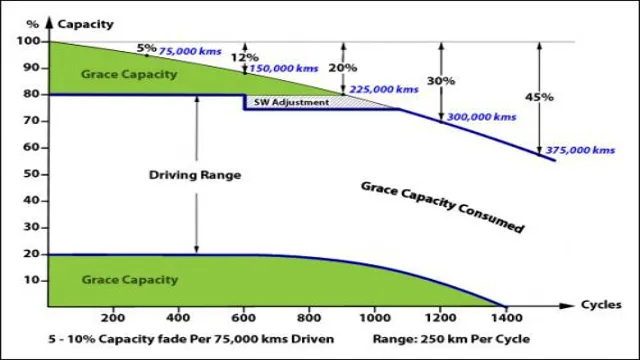

India is facing a growing demand for electric vehicles due to the rising concerns about environmental issues and the increasing need for sustainable transportation. To meet this demand, a new electric car battery plant is being established in Gujarat, India. This plant will produce lithium-ion batteries for electric cars, which are known for their high energy density, long life, and low maintenance costs.

The new plant will help reduce India’s dependence on imported batteries and significantly increase the production of electric cars in the country. With this move, India is taking a major step towards achieving its goal of becoming a global leader in clean energy and sustainable transportation. This development can be seen as an excellent opportunity for the Indian automotive industry to transition towards the use of electric vehicles and foster a sustainable future.

The establishment of this plant marks a significant milestone and opens up new avenues for economic growth while maintaining environmental sustainability, a win-win scenario for everyone.

Sales of EVs In India Increased by 20% in 2020

The demand for electric vehicles in India has been on the rise, as evidenced by the 20% increase in sales in 2020. This trend is a reflection of the growing interest in sustainable transportation options among Indian consumers. The Indian government has been instrumental in driving this shift, providing incentives and subsidies to promote the uptake of EVs.

Additionally, there has been an increase in the availability of charging infrastructure across the country, making EVs a more feasible option for many. The benefits of electric vehicles are numerous, including reduced emissions and lower fuel costs, making them a more economical and environmentally friendly option. With increasing concern about the impact of climate change, the trend towards EVs is likely to continue in the coming years.

It is an exciting time for the automotive industry in India, as more manufacturers introduce new EV models to the market, catering to the growing demand.

Government’s Push towards EV Production and Usage

The demand for electric vehicles (EVs) is rapidly increasing and the government is pushing towards the production and usage of EVs. This push is seen as a positive step towards reducing carbon emissions and improving the environment. The government has initiated various incentives for EV production and sales such as tax credits, rebates, and grants.

Additionally, there has been an increase in charging infrastructure across the country to encourage more people to switch to EVs. The benefits of owning an EV extend beyond just environmental factors, but also financial savings in the long run. With the government’s support, EVs are becoming more accessible and affordable for the general public, allowing for a better future in terms of sustainability and innovation.

Electric Car Battery Plant: A Game Changer for India’s EV Industry

India is taking a big step towards boosting its electric vehicle (EV) industry by setting up an electric car battery plant. This new development is expected to be a game changer and revolutionize the Indian automotive industry by reducing its dependence on imported batteries. Currently, India depends heavily on imported batteries from countries like China, South Korea and Japan.

The aim of this initiative is to help India achieve its goal of transitioning to e-mobility and reducing its carbon footprint. The battery plant will help to lower the cost of lithium-ion batteries and make EVs more affordable for consumers, spurring demand for electric cars in the country. This will also promote local manufacturing, create jobs and attract much needed investment.

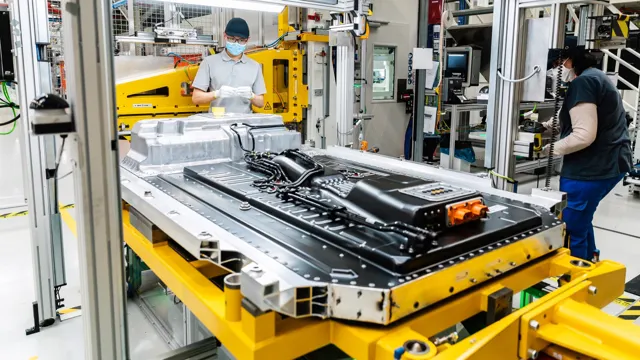

The plant is being set up in collaboration with foreign companies to ensure the latest technology is used. Once operational, this plant is set to increase the production of EVs in India, making a significant impact on the entire EV ecosystem. With this revolutionizing step, India can truly become a leader in the global EV market and contribute towards a cleaner and more sustainable future.

Current Scenario of Battery Manufacturing in India

The current scenario of battery manufacturing in India is evolving rapidly, with the government aiming to make India a hub for electric vehicles (EVs) and battery manufacturing. Recently, Tata Motors and Tata Chemicals have announced plans to build an electric car battery plant in India. This will be a game-changer for India’s EV industry, as the country currently relies heavily on imported batteries to power EVs.

The new manufacturing plant will help reduce the dependence on imported batteries and lead to better pricing for EVs. With the increasing demand for EVs, the need for indigenous battery manufacturing is becoming more important than ever. The plant will not only contribute to the government’s goal of becoming a leader in the EV industry but also create employment opportunities and contribute to the country’s economic growth.

This move by Tata Motors and Tata Chemicals highlights the potential and opportunities in the Indian EV industry, and it is a positive step towards a cleaner and sustainable future for India.

Advantages of Setting up a Battery Plant in India

Setting up an electric car battery plant in India could be a game changer for the country’s EV industry. India has set a target of having only electric vehicles on its roads by 2030, which means a huge demand for batteries that can power these vehicles. Having a battery plant in the country would lead to significant advantages.

Firstly, it would reduce the cost of importing batteries from other countries. Additionally, it would create new job opportunities and provide a boost to the economy. A battery plant in the country also means easy access to batteries for EV manufacturers, eliminating the need for them to import batteries from other countries.

Overall, setting up a battery plant in India would be a substantial step for the country’s EV industry and help drive the country forward towards a greener future.

Leading Players in India’s Electric Car Battery Manufacturing Industry

India’s electric car battery manufacturing industry has been growing rapidly in recent years, with many leading players making significant strides in the field. One such player is the Electric Car Battery Plant, which has emerged as a game changer for India’s EV industry. The plant uses cutting edge technology to manufacture lithium-ion batteries that are essential for electric vehicles, helping to make EVs more affordable and accessible to consumers across India.

The plant has also created numerous job opportunities in the field of green energy, providing support for the government’s push towards sustainability and reducing carbon emissions. With the Electric Car Battery Plant leading the way, India’s electric car industry is set to grow and thrive in the coming years, driving the country towards a brighter and more sustainable future.

Incentives and Opportunities for Electric Car Battery Manufacturing

India is making significant strides in promoting electric car battery manufacturing within its borders. With the government aiming to make electric vehicles account for 30% of all new car sales by 2030, there exists an enormous potential for the country to become an internationally recognized manufacturer of electric vehicle batteries. One of the significant incentives for setting up an electric car battery plant in India is the government’s FAME India Scheme, which provides financial backing to businesses involved in EV manufacturing.

Additionally, low-interest loans, tax exemptions, and land acquisition at reduced prices are made available to companies that invest in the EV battery sector. A few states have taken it a step further and developed their policies to provide additional incentives and assistance to EV manufacturers. With all the incentives available and the vast potential market, it is an opportune time for businesses to explore the possibility of establishing a battery plant in India, thus boosting the growth of the country’s renewable energy sector while creating job opportunities.

Government Subsidies and Tax Incentives

One of the most significant incentives for electric car battery manufacturing is the availability of government subsidies and tax incentives. These programs help to offset the high costs associated with manufacturing batteries, which are a crucial component of electric vehicles. Some of the tax incentives that governments offer include investment tax credits, research and development tax credits, and production tax credits.

In addition, some governments also offer grants and loans to companies that are looking to establish battery manufacturing facilities. These incentives provide a significant opportunity for companies looking to invest in this industry. With the demand for electric cars expected to continue growing, companies that take advantage of these incentives now are likely to enjoy significant benefits in the long run.

By offering subsidies and tax incentives, governments are helping to drive innovation in the electric car battery manufacturing industry and making it easier for companies to get involved.

Opportunities for Foreign Investments in Battery Manufacturing

Foreign investments in battery manufacturing come with various incentives and opportunities. One of the most significant incentives is the shift towards electric vehicles and the increasing demand for electric car batteries. Governments worldwide are committing to electrifying their transportation systems, and they are providing a range of incentives to attract foreign investments in battery manufacturing.

These incentives include tax breaks, grants, and subsidies, reducing costs and lowering obstacles for foreign investors. Additionally, there are opportunities in the supply chain, including the development of lithium-ion battery technologies, which form the backbone of electric car batteries. Foreign investors who can develop cutting-edge battery technologies can take advantage of the emerging electric car market and realize high returns on investment.

Overall, the incentives and opportunities for foreign investors in battery manufacturing show great promise and potential for growth in the near future.

Future of Electric Car Battery Manufacturing in India

Electric car battery manufacturing is on the rise in India, with various companies investing in new plants and facilities to boost production. The consumption of electric vehicles in India is gaining traction as more people become environmentally conscious, and the government is also offering incentives to manufacturers. Several firms such as Suzuki, Exide, and Tata Chemicals have announced their plans to set up electric car battery plants in India.

The key factor that is driving this transition is the push towards cleaner energy sources and lower emissions. With India’s growing demand for electric vehicles, it is essential to have a reliable and efficient production capacity of electric car batteries. This will reduce India’s dependence on imported battery cells and provide more opportunities for local battery production.

Furthermore, local production facilities will create more jobs within the country and boost the overall economy. An electric car battery plant in India will benefit the country immensely in terms of energy independence, job creation, and its goal of a greener future.

Conclusion

In conclusion, the establishment of an electric car battery plant in India marks a significant step towards the nation’s push for cleaner and more sustainable transportation options. With the rise of electric vehicles globally, India’s move towards domestically manufacturing batteries signals an opportunity for economic growth, job creation, and a reduction in carbon emissions. This initiative not only supports the country’s goal of becoming a major player in the EV industry, but also showcases a growing global demand for sustainable solutions.

So, charge up your batteries and get ready for a brighter, cleaner future on India’s roads!”

FAQs

What is the current status of electric car battery plant in India?

Currently, India has a few electric car battery plants in operations such as the one owned by Tata Chemicals in Gujarat and one in Andhra Pradesh by Exide Industries.

Why is it important to have electric car battery plants in India?

It is important to have electric car battery plants in India because it will promote the growth of electric vehicles in the country. Indian government has proposed to make India a 100% EV nation by 2030 and having battery plants will support this goal.

Which companies are planning to build electric car battery plants in India?

Many companies such as Suzuki, Toshiba, and Denso have shown interest in setting up electric car battery plants in India. Indian companies like Mahindra, Amara Raja Batteries, and Bharat Electronics have already started working on the same.

What are the challenges faced by electric car battery plants in India?

Electric car battery plants in India face challenges such as lack of skilled workforce, high initial investments, and infrastructure issues. However, the government has taken initiatives to address these issues through schemes like Faster Adoption and Manufacturing of (Hybrid &) Electric Vehicles (FAME) and Make in India.