Unearthing the Hidden Treasure: The Role of Precious Metals in Electric Car Batteries

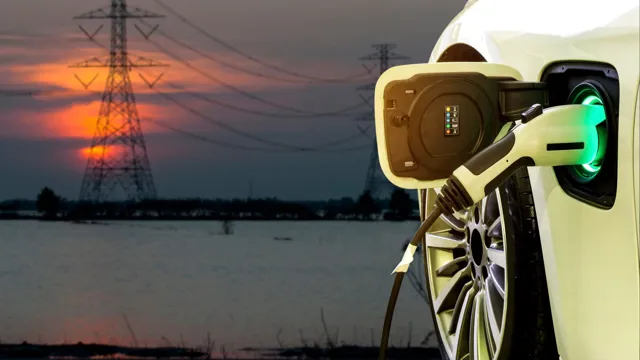

As the world transitions towards more sustainable energy sources, electric vehicles (EVs) have become increasingly popular. However, the ability to store and efficiently transfer energy remains one of the main challenges for EVs. This is where precious metals come into play.

Precious metals such as cobalt, nickel, and lithium are essential components in the batteries that power electric cars. Without these metals, EVs would not function as they currently do. The use of these metals in batteries has not only helped address some of the issues that traditional gasoline-powered cars face, but it has also opened up new avenues for sustainable technology.

In this blog post, we will be exploring the role of precious metals in electric car batteries, and how they are contributing to a greener, cleaner future.

Introduction

Electric car battery technology has come a long way in the past decade. One of the most important components of these batteries are the precious metals like lithium, cobalt, and nickel. These metals are not only expensive, but also rare, which makes electric car batteries costly to produce.

However, as more companies invest in electric vehicle technology, the demand for these metals is expected to rise significantly. This will require a new strategy to source and recycle these metals efficiently. While experts suggest that alternative materials could eventually replace some of these precious metals, the transition is likely to be a slow process.

Therefore, increasing production, improving recycling methods, and exploring new sources and alternatives will be important to make electric cars more accessible and affordable in the future.

Why electric car batteries need precious metals

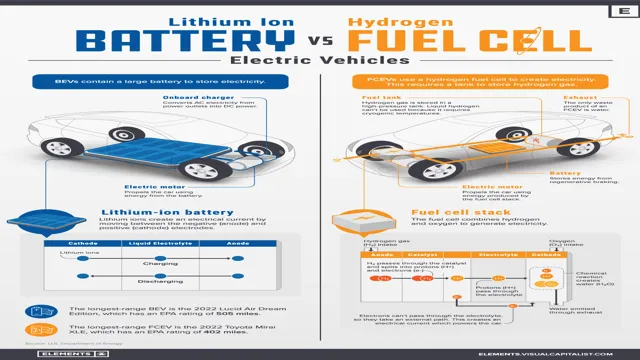

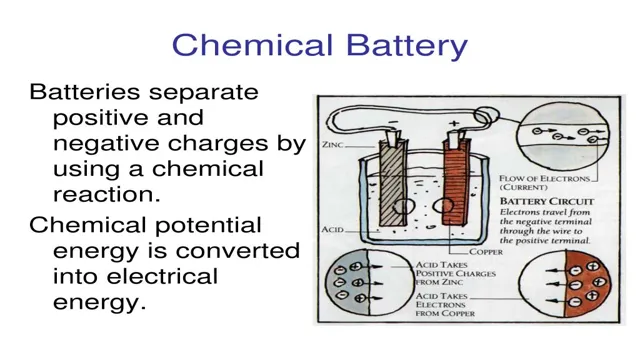

Electric car batteries are an essential component of sustainable mobility. They provide the power needed to drive electric cars and reduce emissions compared to traditional gasoline-fueled cars. However, what many people may not know is that electric car batteries require precious metals to function.

These precious metals, such as cobalt, lithium, and nickel, are used in the battery’s cathode and anode. Without these metals, the battery’s capacity, charge time, and overall performance would be severely compromised. The reliance on precious metals creates a challenge for the electric car industry, as the supply chain for these metals is limited, and demand is increasing rapidly.

What are the common precious metals used in electric car batteries?

Precious metals are essential components in building electric car batteries, and the most common metals used are cobalt, nickel, and lithium. These metals can be found in the cathodes of the battery and are responsible for storing energy that powers the electric vehicle. Cobalt is an incredibly durable metal that can withstand high temperatures without melting, making it an ideal material for electric car batteries.

On the other hand, nickel gives the battery a higher energy density, which translates into more power and a longer range. Lastly, lithium is the main component in the battery’s electrolyte, which is responsible for conducting electricity between the cathode and the anode. By using these three precious metals, electric car manufacturers can build batteries that are efficient, long-lasting, and eco-friendly.

Environmental Impact

Did you know that electric cars use precious metals in their batteries? These metals, such as cobalt, nickel, and lithium, are essential for the production of high-performance batteries that power electric cars. But the extraction and processing of these metals have significant environmental consequences. Mining for these precious metals causes soil erosion, deforestation, and water pollution.

Moreover, the manufacturing of batteries for electric cars also contributes to greenhouse gas emissions. However, research and development are ongoing to find sustainable alternatives to these precious metals, which could reduce the environmental impact of electric car battery production. So the next time you drive an electric car, remember the hidden environmental cost of its battery.

However, choosing to drive an electric car is still a positive step towards reducing carbon emissions and protecting the environment.

How mining of precious metals affects the environment

Mining precious metals has a significant impact on the environment. The extraction process involves the removal of vast amounts of rocks and soil, leading to soil erosion and land degradation. Apart from that, mining produces toxic waste, which can contaminate the soil and water sources.

It can also lead to the disruption of ecosystems and wildlife habitats, causing species to go extinct. Another area of concern is the use of water, specifically in areas where it is scarce. Mining consumes a significant amount of water, and when combined with chemical use, can pollute water sources, making them undrinkable.

In addition to affecting the environment, mining activities can have a detrimental impact on the health of local communities. Workers in mines are exposed to toxic chemicals and heavy metals that can cause long-term health problems. Overall, the environmental impact of mining precious metals is a significant concern that must be carefully evaluated and addressed through sustainable practices.

How recycling of electric car batteries can reduce environmental impact

Electric car batteries have been lauded in recent times for their impressive performance, zero-emission features, and advanced technology; however, the environmental impact of battery disposal may not be as impressive. Once the batteries lose their vitality after several years of use, they become unusable and are eventually discarded. The disposal of lithium-ion batteries used in electric cars can lead to tremendous environmental damage due to the discharge of toxic elements that occur when incinerated.

Recycling, on the other hand, can greatly reduce this impact, and it has been found to be a more efficient and cost-effective method of battery disposal. The recycled materials can be used to manufacture new batteries or other products, reducing the need to extract and mine for new materials, and ultimately leading to a significant reduction in carbon emissions. The recycling process is also crucial to enhance the economic and sustainable life cycle of electric vehicles.

Statistics on the growth of electric car battery recycling

As electric cars continue to rise in popularity, so does the need for proper battery recycling. Fortunately, statistics show that the growth of electric car battery recycling is steadily increasing. In fact, in 2020 alone, more than 150,000 metric tons of lithium-ion batteries were recycled globally.

This not only benefits the environment by reducing harmful waste but also helps to preserve valuable resources, such as cobalt and nickel. The demand for electric car batteries is expected to increase by over 500% by 2030, making the proper recycling of these batteries more important than ever. The recycling process itself also has environmental benefits, as it reduces carbon emissions and water usage compared to extracting new materials.

By continuing to prioritize the recycling of electric car batteries, we can ensure a more sustainable future for both ourselves and the planet.

Cost Considerations

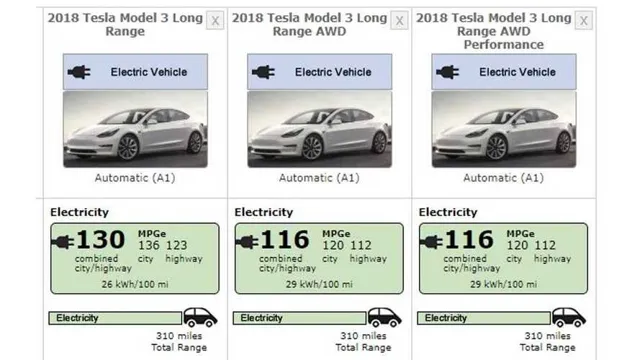

When considering the cost of electric cars, one important factor to keep in mind is the use of precious metals in their batteries. These metals, such as lithium, cobalt, and nickel, are necessary for producing the energy storage technology that allows electric cars to travel long distances on a single charge. However, the demand for these metals has led to a significant increase in the cost of manufacturing electric car batteries.

Moreover, the production of these metals can also have significant environmental impacts. Many automakers are striving to develop alternative battery technologies that are more sustainable and rely less on these precious metals. While these alternatives may not be as efficient as traditional batteries, they could potentially help to reduce the overall cost of electric cars, making them more accessible to a wider range of consumers.

The effect of precious metal prices on the cost of electric car batteries

One of the biggest cost considerations for electric car manufacturers is the price of precious metals, specifically cobalt, nickel, and lithium. These metals are crucial components in the batteries that power electric cars. With the increasing popularity of electric vehicles, demand for these metals has grown, resulting in higher prices.

In fact, the cost of these metals can make up a significant portion of the total cost of an electric car battery. This leads to the question: how do fluctuations in precious metal prices impact the cost of electric car batteries? If the prices of these metals rise too high, it could make electric cars less affordable and less accessible to consumers. However, as researchers continue to find ways to reduce the amount of precious metals needed in batteries, it’s possible that electric car manufacturers will be able to minimize the impact of rising prices and offer more cost-effective solutions to consumers.

How investment in R&D can lead to innovation in battery technology

Investing in research and development (R&D) is critical in driving innovation in battery technology. However, one of the biggest challenges is cost considerations. Developing new technologies can be expensive, which in turn can increase the cost of batteries which are a key component in many products including electric vehicles.

That being said, investment in R&D can result in new breakthroughs and innovations, leading to more efficient and less expensive battery production processes. It’s important to understand that the initial cost of investing in R&D will ultimately pay off in the long run through increased efficiency and lower cost structures. Ultimately, without investment in R&D, we risk stagnation in technological progress in the battery industry, hindering efforts to create more sustainable and eco-friendly energy solutions.

Conclusion

In the world of electric cars, the power truly lies in the battery’s precious metals. These elements, from lithium to cobalt and beyond, are the backbone of the electric car’s ability to go the distance. And while they may be rare and costly to mine, their sustainable impact on the environment makes them invaluable.

So, next time you’re zipping around town in your electric vehicle, remember that the real star of the show is the precious metals powering your ride.”

FAQs

What are the precious metals used in electric car batteries?

The main precious metals used in electric car batteries are cobalt, nickel, and lithium.

Why are precious metals used in electric car batteries?

Precious metals, such as cobalt and nickel, are used in electric car batteries due to their high energy storage capacity and ability to withstand frequent charging and discharging cycles.

Are precious metals in electric car batteries environmentally sustainable?

The extraction and disposal of precious metals used in electric car batteries can have negative environmental impacts. However, efforts are being made to improve the sustainability of their production and recycling.

How long do electric car batteries made with precious metals last?

The lifespan of electric car batteries made with precious metals varies depending on factors such as usage, charging habits, and temperature. However, on average, they can last between 5-10 years.