Powering Up: An Insight Into the Growing Electric Car Battery Production Capacity

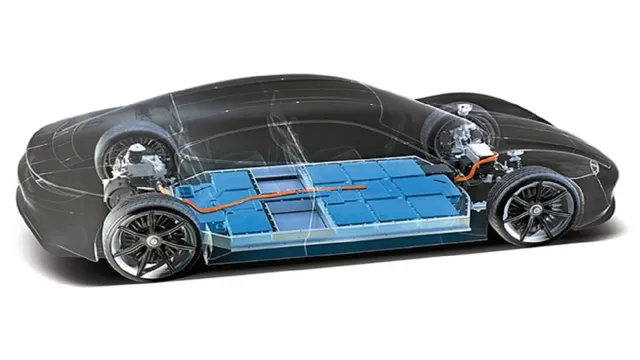

Electric vehicles have been gaining popularity over the years as a cleaner and more sustainable alternative to traditional gas-powered cars. However, one of the biggest concerns surrounding this shift to electric cars is the production capacity of their batteries. With more and more car manufacturers investing in electric car technology, the production capacity of these batteries needs to keep up with the demand to ensure a smooth transition towards a more sustainable future.

In this blog post, we will dive into the current state of electric car battery production capacity and explore possible solutions to overcome the challenges ahead.

Overview of Global Production Capacity

Electric car battery production capacity is increasing around the world as consumers demand more electric vehicles (EVs). As of 2021, China dominates the global EV market and also has the largest battery production capacity, with major manufacturers such as CATL, BYD, and LG Chem producing millions of batteries annually. In Europe, Tesla’s Gigafactory Berlin and France’s ACC Green Energy Battery Facility are ramping up production, while the United States is home to Tesla’s original Gigafactory and the new Gigafactory Texas.

Other notable battery manufacturers include Panasonic in Japan and South Korea’s Samsung SDI. With governments pushing for stricter emissions regulations and EVs becoming more affordable, the demand for batteries will only continue to grow, prompting manufacturers to further increase their production capacity and improve battery technology.

Current State of Electric Car Battery Production

The current state of electric car battery production is rapidly changing as the demand for cleaner and more efficient vehicles increases. Globally, the production capacity for electric vehicle batteries has increased significantly over the past few years, with China leading the charge. In fact, China currently accounts for more than half of the world’s total electric car battery production capacity.

This growth is fueled by government support, technological advances, and collaboration between automakers and battery manufacturers. Other countries, including the United States and Europe, are also investing heavily in electric car battery production and working towards increasing their capacity. With this increase in production, it is expected that electric vehicle batteries will become more affordable, making electric vehicles more accessible to consumers.

Overall, the future of electric car battery production looks promising, as countries around the world work towards creating a more sustainable and cleaner transportation system.

Projected Growth in Electric Car Battery Production

The projected growth in electric car battery production is set to soar as global demand for electric vehicles continues to rise. With environmental concerns and the need to reduce carbon emissions becoming increasingly prominent, many countries worldwide have committed to transitioning away from traditional gasoline-powered cars and investing in electric cars instead. As a result, estimates suggest that electric car battery production could reach 700 GWh by 2025, with China leading the way in terms of production capacity.

This surge in production capacity will not only promote sustainable driving but also pave the way for a significant reduction in the cost of electric car batteries in the future, making electric cars more affordable for consumers. The future looks bright for electric cars, and it’s exciting to see how technological advancements in the battery space will shape the automotive industry moving forward.

Leading Producers of Electric Car Batteries

When it comes to electric car battery production capacity, a few leading producers immediately come to mind. One of these is Tesla, which is renowned for its cutting-edge battery technology and commitment to sustainability. In 2020, the company’s Gigafactory in Nevada had an annual production capacity of 40 GWh per year and is set to increase its total capacity in the coming years.

Another notable electric car battery producer is Panasonic, which is Tesla’s main supplier. The company has been manufacturing batteries for over 40 years and has recently expanded its production capacity at its Gigafactory in Japan. Chinese battery maker CATL is also a major player in the market, with an estimated annual production capacity of 70 GWh in 2020.

With more and more people making the switch to electric vehicles, these companies are investing heavily in battery production to meet the growing demand and lead the way towards a more sustainable future.

Company A: Production Capacity and Expansion Plans

Company A is one of the leading producers of electric car batteries, boasting a high production capacity of over 10,000 batteries per day. With such impressive capabilities, they’re able to satisfy the growing demand for eco-friendly car batteries from manufacturers worldwide. In line with this demand, Company A is planning on expanding their production capacity even further within the next few years.

They’re currently investing heavily in research and development to improve battery efficiency and durability, ensuring that they maintain their place as a market leader in the electric car industry. As the world shifts towards electric vehicles, it’s exciting to see such innovative companies like Company A leading the way with cutting-edge production methods and forward-thinking expansion plans.

Company B: Production Capacity and Expansion Plans

Company B is one of the leading producers of electric car batteries in the market. The company has a tremendous production capacity and offers a wide range of batteries for different types of electric cars. In recent years, the demand for electric cars has increased exponentially, and Company B has been expanding its production capacity to meet the high demand.

The company has invested heavily in research and development to create batteries that are more efficient, have a longer life cycle, and are more cost-effective. Company B has also been working on developing new technologies, such as solid-state batteries, that can potentially make electric cars more mainstream. Overall, Company B is a pioneer in the electric car battery industry and is well-positioned to continue to grow and expand its offerings.

Company C: Production Capacity and Expansion Plans

Company C is one of the leading producers of electric car batteries, with an impressive production capacity that has helped it establish its presence in the market. The company has been focusing on expanding its operations and has plans to further increase its production capacity in the coming years. This move is in response to the growing demand for electric cars, which has been on a steady rise in recent years.

To cater to this demand, Company C has been working on developing new and improved battery technologies that can provide longer ranges, faster charging times, and increased durability. The company understands the importance of staying ahead of the competition, and its efforts to expand its production capacity and innovate its products are a testament to its commitment to meeting the evolving needs of the market. It is no wonder that Company C is considered one of the most reliable and trustworthy suppliers of electric car batteries, a reputation it has earned through years of hard work and dedication to the cause.

Impact of Policy on Electric Car Battery Production Capacity

Electric car battery production capacity has been impacted by various policies implemented by governments around the world. Some countries have provided incentives for the expansion of production capacity in the electric vehicle industry, while others have imposed strict regulations and taxes on battery manufacturing companies. These policies have influenced the market demand for electric car batteries and consequently affected the supply chain management for the raw materials required to make them.

Additionally, the cost of producing batteries has also been affected by these policies. However, despite these challenges, the demand for electric vehicles and batteries is continuously increasing, and companies are investing heavily in research and development to improve battery technology and production efficiency. This is leading to significant advancements in electric car batteries, which will ultimately lead to more affordable and accessible electric cars for everyone.

Government Incentives for Battery Production

The government’s initiatives to promote electric car battery production have had a significant impact on the global market. In recent years, many countries have implemented policies such as tax incentives, grants, and subsidies to promote the development of battery manufacturing. This has led to a surge in the battery’s production capacity, which has resulted in a decline in the prices of electric vehicles.

Consequently, the demand for electric vehicles has risen in the past couple of years, and manufacturers have responded by expanding their production lines. The increase in demand has also encouraged many start-ups to enter the market. This competition has resulted in more innovative, efficient, and cost-effective batteries that have further boosted the adoption rate of electric vehicles.

In conclusion, government incentives have played a critical role in the growth of electric car battery production, and as the market continues to evolve, we can expect to see more policies in the future to encourage sustainable growth.

Impact of Environmental Regulations on Battery Production

One of the biggest challenges facing the electric car industry is the capacity to manufacture enough batteries to keep up with demand. Environmental regulations have a significant impact on battery production, as the materials used to make batteries are often highly toxic and can cause harm to both people and the environment. While some regulations may increase costs, they also serve as a necessary safeguard against the negative impacts of battery production.

For example, limits on emissions and waste disposal help to ensure that batteries are manufactured and disposed of in a responsible manner. Moreover, such policies incentivize manufacturers to invest in developing new materials and processes that are safer and more sustainable, thus leading to greater innovation and progress in the industry. Ultimately, policies that strike a balance between protecting the environment and promoting growth within the electric car industry will be crucial in achieving a cleaner, more sustainable future.

Future of Electric Car Battery Production Capacity

Electric car battery production capacity is on the rise as manufacturers compete to meet the increasing demand for electric vehicles. In recent years, we’ve seen significant advancements in battery technology, which has reduced costs and increased efficiency. As a result, automakers are increasing their investment in battery production facilities, with some investing billions of dollars to increase their production capacity.

In addition, we’re seeing new players enter the market, such as Tesla’s Gigafactory and China’s CATL, which are expected to further increase battery production capacity. With the demand for electric vehicles only expected to grow in the coming years, there will undoubtedly be further developments in battery technology and production capacity. It’s an exciting time for the industry, and we can expect to see significant progress in the near future.

Conclusion

In conclusion, the current state of electric car battery production capacity is like a charged-up Tesla. It’s full of potential and promise, but not quite at its full speed just yet. With investments and advancements in technology, we’re sure to see sizable strides in both production and efficiency in the near future.

So buckle up, because the electric vehicle revolution is just getting started!”

FAQs

What is the current global production capacity for electric car batteries?

The current global production capacity for electric car batteries is estimated to be around 455 GWh per year as of 2021.

What factors influence the production capacity of electric car batteries?

Factors that influence the production capacity of electric car batteries include the availability of raw materials, manufacturing processes and techniques, capital investment, and government regulations and policies.

Which countries are the major players in electric car battery production?

Currently, China, South Korea, and Japan are the major players in electric car battery production, accounting for the majority of global production capacity.

How is the production capacity of electric car batteries expected to change in the future?

The production capacity of electric car batteries is expected to increase in the future, driven by technological advancements, growing demand for electric vehicles, and investments in battery manufacturing infrastructure. By 2030, some estimates suggest that global production capacity could reach 1 TWh per year.