The Shocking Truth Behind Electric Car Battery Production Cost: A Deep Dive into Affordability

It’s common knowledge that the future of transportation is electric, but something people rarely consider is the cost of producing the batteries that power these eco-friendly vehicles. With the rising popularity of electric cars, the demand for lithium-ion batteries has skyrocketed, and battery production costs have come under scrutiny. The question arises: what is the true cost of producing an electric car battery? Is it as expensive as people think, or is it a viable and economical alternative to traditional combustion engines? This blog will delve into the concept of electric car battery production cost, highlighting the factors that impact its cost and analyzing how it stacks up against the cost of a gasoline-powered car.

So, let’s put our thinking caps on and explore the world of electric car battery production cost!

Overview of Electric Car Battery Production

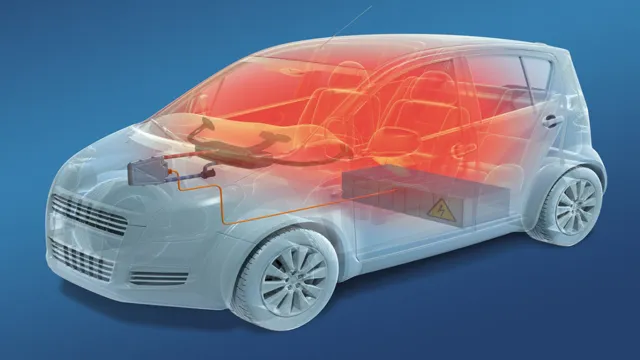

Electric car battery production cost is one of the crucial factors in determining the growth of the electric vehicle industry. The battery pack is the most expensive component in an electric vehicle, accounting for up to 40% of the total cost. The production process of electric car batteries involves high-level technology and complicated manufacturing procedures, which increase the production cost.

However, with the advancements in technology and increased demand for electric vehicles, the production cost of batteries has been significantly decreasing. Governments and manufacturers have been investing in research and development to bring down the cost of electric vehicle batteries further. The reduction in the production cost of batteries will make electric vehicles more affordable and hence more accessible to the masses, making it an efficient and eco-friendly mode of transportation.

Cost Breakdown

When it comes to electric car battery production, there are several things to consider in terms of cost breakdown. The first factor is the materials used to create the battery, such as lithium, cobalt, nickel, and manganese. These materials can be quite expensive, making up a significant portion of the overall cost.

But in recent years, manufacturers have been exploring alternative materials and processes to reduce the cost of batteries. Another factor to consider is the manufacturing process itself, which requires specialized equipment and skilled labor. However, advancements in automation and production efficiency have helped to lower these costs.

Additionally, the cost of research and development for electric car batteries is also a significant factor. As technology advances and new methods are discovered, these costs can shift as well. All of these factors must be taken into account when considering the overall cost of electric car batteries.

Factors Affecting Production Costs

When it comes to electric car battery production, there are a few key factors that can affect the production costs. One of the primary factors is the type of battery being produced. Lithium-ion batteries, for example, are currently the most popular type of electric car battery, but they can be expensive to produce due to the cost of the raw materials.

Additionally, the size and capacity of the battery can impact production costs, as larger batteries typically require more materials and resources to produce. Other factors that can affect production costs include the production method, efficiency of the manufacturing process, and labor costs. However, as the demand for electric cars continues to grow and advancements are made in battery technology, it is likely that production costs will decrease over time.

Nevertheless, it’s important to consider the various factors that go into production costs when evaluating the cost-effectiveness of electric vehicles.Keyword: electric car battery production

Comparison of Production Costs for Different Battery Technologies

Electric car battery production costs vary greatly depending on the technology used. Currently, lithium-ion batteries are the most widely used battery technology in the electric vehicle industry. Despite their dominance in the market, lithium-ion batteries are relatively expensive to produce.

This is due to the high cost of raw materials such as cobalt and lithium. However, advancements in technology and improvements in production processes have led to a decline in production costs. Solid-state batteries, which use a solid electrolyte instead of a liquid one, have the potential to reduce production costs significantly.

These batteries are safer, more stable, and have a higher energy density than their traditional counterparts. However, they are still in the early stages of development, and it may be some time before they can be produced on a large scale. Ultimately, as demand for electric vehicles grows, battery manufacturers will be forced to continue to innovate to drive down production costs.

Lithium-Ion Batteries

Lithium-ion batteries have become popular due to their superior energy density and long lifespan. However, they are also more expensive to produce compared to other battery technologies like lead-acid and nickel-cadmium. This is because the materials needed for Lithium-ion batteries, such as cobalt and nickel, are scarce and expensive.

Additionally, the complex manufacturing process involved in making Lithium-ion batteries also contributes to their high cost. Despite this, Lithium-ion batteries are still preferred due to their better performance and environmental benefits. As demand for renewable energy storage solutions increases, the cost of production for Lithium-ion batteries is expected to decrease due to advancements in technology and economies of scale.

Solid-State Batteries

Solid-State Batteries When it comes to energy storage systems, such as batteries, there are several factors to consider, including production costs. Solid-state batteries have received a lot of attention recently due to their potential advantages over traditional lithium-ion batteries. Solid-state batteries are safer and more energy-dense than their liquid counterparts, but the current cost of production for these batteries is significantly higher.

In comparison, lithium-ion batteries remain the most cost-effective option, owing to their widespread production and established supply chain. However, as the demand for more advanced energy storage solutions grows, the cost of solid-state batteries is expected to decrease significantly. In the coming years, it is possible that solid-state batteries will become a competitive alternative to traditional lithium-ion batteries in terms of production costs, but this will depend on continued technological advancements and more widespread adoption.

Lithium-Iron-Phosphate Batteries

When it comes to the production costs of lithium-iron-phosphate (LiFePO4) batteries in comparison to other battery technologies, there are some interesting differences to consider. While LiFePO4 batteries may have higher upfront costs, their long-term durability and stability make them more cost-effective in the long run. Plus, their raw materials are more readily available and less expensive than those used in other battery types, such as cobalt-based batteries, often leading to lower production costs.

Additionally, LiFePO4 batteries have a longer lifespan, meaning they need to be replaced less frequently, adding further to their overall cost-effectiveness. All of these factors make LiFePO4 batteries an attractive choice for many applications, from consumer products to renewable energy storage systems.

Future Projections and Trends

Electric car battery production cost is a crucial factor in determining the success of electric vehicles and the growth of the industry. With a rising demand for EVs and government incentives to reduce carbon emissions, significant advancements have been made to lower production costs of the batteries. Tesla’s efforts to produce its own batteries and reduce costs have brought prices down to $125 per kWh, making EVs more affordable and competitive with traditional gasoline cars.

However, challenges remain, including the high cost of raw materials, such as lithium, cobalt, and nickel, used to manufacture batteries. To counter this, researchers are exploring alternative battery chemistries that are more sustainable and cost-effective, such as solid-state batteries. As the industry continues to innovate and improve battery technologies, it is expected that production costs will continue to decrease.

Eventually, electric cars may become more accessible to everyone, accelerating the transition to a cleaner and sustainable future.

Projected Cost Reductions for Electric Car Batteries

Electric car batteries have been a game-changer in the automotive industry, but their cost has been a major concern for buyers. However, projections and trends suggest that prices for electric car batteries are forecasted to drop significantly, making electric vehicles more affordable. Experts predict that cost reductions of up to 50% are achievable by 202

This forecast is due to advancements in battery technology, which includes improved materials, enhanced production processes, and economies of scale as production ramps up. As electric car batteries become more economical, they will become more accessible, which in turn, will accelerate the adoption of electric vehicles worldwide. With these cost reductions, there will likely be even more innovation and advancement in the electric vehicle market, leading to continued reductions in costs.

Impact of Technological Advancements on Production Costs

As technology continues to advance, the impact on production costs is getting more significant. With the introduction of automation, robotics, and other sophisticated machinery, companies are now able to produce goods at lower costs and in greater quantities. However, as technology continues to evolve, so too does the need for specialized workers to operate and maintain these machines.

This has resulted in an increase in the cost of labor, especially for those with specialized skills in maintenance and repairs. As a result, many companies have started to invest in training their employees on how to use these machines, which has helped to lower the cost of labor while increasing productivity. Moving forward, it is expected that technology will continue to play a significant role in production costs.

Specifically, advancements in artificial intelligence and machine learning are expected to help companies make more data-driven decisions, which will help to reduce errors and improve efficiency. Additionally, the use of 3D printing technology is expected to lower the cost of production by allowing companies to produce items on demand, reducing the need for bulk ordering and warehousing. As a result, while the initial investment in technology may be high, the long-term cost savings can prove to be extremely beneficial for companies looking to improve their bottom line.

Conclusion and Takeaways

In the race for sustainable transportation, the electric car has undoubtedly taken the lead, but the high battery production costs have been a major roadblock. However, with advancements in technology and scaling up of production, the cost of electric car batteries has steadily decreased. Furthermore, with the massive potential for renewable energy integration, the future looks bright for electric cars, and we might soon witness a world where transportation is not just efficient but also environmentally responsible.

So if you’re wondering about the cost of producing an electric car battery, rest assured that it’s on a downward trajectory, and the future looks ever more electrifying!”

FAQs

What is the current average cost of producing an electric car battery?

The current average cost of producing an electric car battery is around $137 per kilowatt-hour.

What factors contribute to the production cost of an electric car battery?

The production cost of an electric car battery depends on several factors including the type and quality of battery cells used, the cost of raw materials like nickel, lithium, and cobalt, research and development expenses, and manufacturing costs.

How much has the production cost of electric car batteries decreased in recent years?

The production cost of electric car batteries has decreased significantly in recent years, from around $1,100 per kilowatt-hour in 2010 to around $137 per kilowatt-hour in 2020.

Will the production cost of electric car batteries continue to decrease in the future?

Yes, experts predict that the production cost of electric car batteries will continue to decrease in the future as new, more efficient battery technologies are developed and economies of scale are achieved through increased production.