Shocking Truths: Uncovering the Environmental Impact of Electric Car Battery Production Emissions

Do you ever wonder about the impact of electric car batteries on emissions? As more and more people make the switch to electric vehicles, it’s important to understand the environmental implications of this technology. Electric car batteries represent a key component of these vehicles, allowing them to run without relying on fossil fuels. But how do these batteries affect overall emissions? In this blog, we’ll explore the relationship between electric car batteries and emissions, diving into the details of this complex issue.

From the environmental benefits of electric cars to the challenges associated with battery disposal and production, we’ll look at the factors that make this topic both fascinating and complicated. So, let’s dig in and learn more about the role electric car batteries play in the fight against climate change.

The Problem: Carbon Footprint of Battery Production

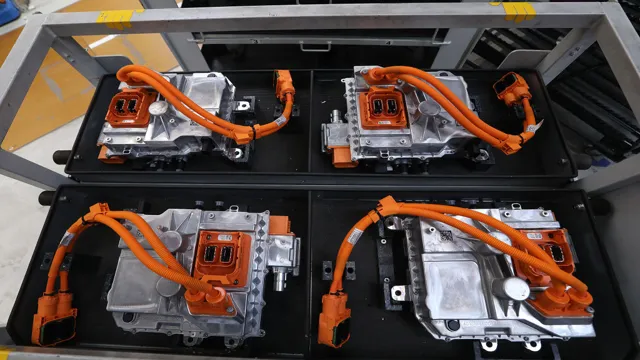

It’s no secret that electric cars are considered a greener alternative to their gas-guzzling counterparts. However, the production of their batteries poses a significant hurdle in achieving truly sustainable transportation. The creation of an electric car battery involves several stages, each requiring copious amounts of energy and materials.

For example, the mining of minerals like lithium and cobalt is a highly resource-intensive process, often occurring in countries with lax environmental regulations. Additionally, the manufacturing of the battery cells and their assembly into modules and packs all require energy and contribute to greenhouse gas emissions. All these factors add up, and studies have shown that the production of an electric car battery can generate significant amounts of carbon emissions, potentially canceling out the savings made during the car’s lifetime.

As demand for electric cars grows, so too must our focus on finding more sustainable methods of battery production.

Data on Carbon Emissions from Battery Production

When we think about the carbon footprint of renewable energy sources like electric cars, we often forget to consider the carbon emissions produced during the manufacturing of their lithium-ion batteries. These batteries are made from materials that require intensive mining and processing, which results in a significant carbon footprint. For example, the production of an average electric car battery emits around 74-139 kg of CO2eq/kWh, which is a large amount considering the average car battery has an energy capacity of 10 kWh.

This means that the carbon emissions produced during battery production can outweigh the emissions saved from driving an electric car for some time. However, advancements in battery technology and manufacturing processes are constantly being made to reduce the carbon footprint of batteries and make them more sustainable for the environment.

Factors that Contribute to Battery Production Carbon Footprint

As the demand for electric vehicles (EVs) and other battery-powered technologies rises, concern about their environmental impact grows as well. One key factor contributing to the carbon footprint of battery production is the extraction, processing, and transportation of raw materials like lithium, cobalt, and nickel. These materials are often found in environmentally sensitive areas, which can lead to habitat destruction, water pollution, and other negative consequences.

Another major contributor to the carbon footprint of battery production is the energy used in processing and manufacturing. Traditional production methods rely heavily on fossil fuels, including coal and oil, which emit large amounts of greenhouse gases. However, innovations in renewable energy sources and more efficient production techniques are helping to reduce the carbon footprint of battery production and make these technologies more sustainable in the long run.

Possible Solutions: Innovations in Battery Technology

Looking for ways to reduce electric car battery production emissions is essential for creating a more sustainable future. One possible solution is to innovate in battery technology. Researchers around the world are working on developing new materials and technologies that can make batteries more efficient and environmentally friendly.

Some of these innovations include using solid-state electrolytes instead of liquid ones, which can reduce the risk of fires and improve energy density, and using recycled materials for battery components, which can reduce waste and cut down on emissions from mining and refining. Other approaches include developing advanced charging technologies that can make charging faster and more convenient, as well as exploring new battery chemistries that can offer higher energy density and longer lifespan. By investing in these innovations, we can create a cleaner, more sustainable energy future while also meeting the growing demand for electric cars.

Newer and Better Materials for Battery Production

With the increasing demand for sustainable energy solutions, battery technology is continuously improving. One effective way to achieve this is through the use of newer and better materials for battery production. Lithium-ion batteries are currently the most common type of battery used in electric vehicles and many other applications.

However, researchers are exploring the use of different materials, such as sodium and solid-state batteries, to improve energy storage and safety. Sodium batteries, for instance, have the potential to be cheaper and more abundant than lithium-ion batteries. At the same time, solid-state batteries could offer higher energy density and longer lifespan.

These innovations are still in the early stages of development, but they offer a promising glimpse into the future of battery technology. So, with the slowly depleting limited resources of lithium, using other metals like sodium, magnesium, and aluminum may be the newer solution in battery production.

Recycling and Reusing Batteries in the Future

In the near future, recycling and reusing batteries will become a critical aspect of sustainable practices. As battery usage continues to skyrocket, it is essential to find innovative solutions to handle the increasing amount of battery waste. Innovations in battery technology hold the key to solving this problem.

One possibility is the development of advanced materials that can be used to create more efficient, longer-lasting batteries that can be recycled more easily. Another option is creating batteries with greater capacity to store energy and longer lifespan to minimize the amount of battery waste being generated. By utilizing these innovations, we can significantly reduce our environmental impact and move towards a more sustainable future.

Alternative Energy Sources Used in Battery Production

Alternative Energy Sources Used in Battery Production When we think about alternative energy sources, we often think of solar or wind power. But did you know that these sources can also be used in the production of batteries? One possible solution to the environmental impact of battery production is to use these alternative energy sources to power the factories that produce them. This not only reduces the carbon footprint of the production process but also ensures that the energy used to create the batteries is sustainable.

By utilizing multiple different alternative energy sources like geothermal and hydroelectric power, battery production can become a greener and more efficient process. Additionally, some companies are looking at innovative ways to make batteries themselves more environmentally friendly. For example, some companies are experimenting with using recycled materials in their batteries, further reducing their impact on the environment.

As technology continues to advance, we can expect to see even more creative solutions to the environmental challenges posed by battery production.

The Progress: Reducing Carbon Footprint of Batteries

Electric car battery production emissions have long been a concern for environmentalists. Though electric vehicles are seen as a cleaner alternative to traditional gasoline-powered cars, the carbon footprint of producing their batteries can be significant. However, steps have been taken to reduce these emissions.

Manufacturers are utilizing more renewable energy sources, such as wind and solar, to power their factories. They are also exploring new chemical processes that can reduce the amount of energy needed to produce the batteries. In addition, some companies are beginning to implement closed-loop manufacturing systems, where the materials used in production are recycled and reused.

These efforts are helping to make electric vehicles even more environmentally friendly, and may have important implications for the future of transportation. While there is still progress to be made, the reduction in carbon emissions from electric car battery production is an encouraging step in the right direction.

Case Studies of Car Manufacturers

Car manufacturers around the world have been making significant strides towards reducing the carbon footprint of their battery production processes. Through collaborations with tech companies and other automakers, car manufacturers have been developing new technologies that can produce batteries more sustainably. For instance, one such technology involves using recycled materials in battery production, which helps to reduce carbon emissions typically associated with the process.

Additionally, electric vehicle batteries are also becoming more efficient, which means they use less energy to manufacture and can store more power for longer durations. By taking such measures, automakers can not only reduce their carbon footprint significantly but they can also make electric vehicles more accessible to a wider audience. As a result, everyday people can contribute to lowering carbon emissions by switching to electric vehicles, which is essential in fighting climate change.

Government Initiatives and Policies in Support of Sustainable Battery Production

As the world shifts towards a more sustainable energy future, governments are taking steps to support the production of sustainable batteries. One example of this is the European Union’s Battery Regulation, which aims to reduce the environmental impact of batteries by requiring manufacturers to comply with certain sustainability criteria. Additionally, governments are investing in research and development to improve the efficiency and sustainability of battery production.

For instance, the U.S. Department of Energy’s Sustainable Transportation Program provides funding for projects that aim to reduce the carbon footprint of batteries and make them more affordable.

These initiatives are crucial for making sustainable batteries a reality and reducing the carbon footprint of the transportation industry. By promoting sustainable battery production, governments can help pave the way for a cleaner and more sustainable future.

The Future: A Greener Battery Production Process

As the demand for electric vehicles grows, so does the concern about the environmental impact of electric car battery production emissions. Fortunately, the future of battery production looks promising, with several companies already exploring greener methods such as using renewable energy sources, reducing water usage, and adopting closed-loop recycling processes. Additionally, researchers are developing new battery chemistries that utilize less harmful materials and result in fewer emissions during production.

These innovations will not only reduce the environmental impact of battery production but also make electric vehicles more efficient and affordable. In the future, we can expect to see a significant reduction in the carbon footprint of electric car battery production, making electric vehicles a truly sustainable option for transportation.

Conclusion

In the race towards renewable energy and reducing carbon footprints, electric cars have emerged as a promising alternative to the traditional fossil-fuel guzzlers. However, the production of their batteries remains a significant concern due to the high emissions associated with it. Like with any technological advancement, we must weigh the short-term costs against the long-term benefits.

The potential gains in reducing the impact of transportation on the environment are significant, and with ongoing research and development, we can hope to find more sustainable ways of producing electric car batteries. Until then, let us drive towards a brighter, cleaner future, but with a mindful consideration of our impact on the planet.”

FAQs

How does electric car battery production impact the environment?

Electric car battery production can have a significant environmental impact due to the mining and processing of the materials used, such as lithium and cobalt. This can lead to increased emissions and negative impacts on local ecosystems.

Are there any eco-friendly alternatives to traditional electric car batteries?

Yes, there are several companies developing alternative battery technologies such as solid-state batteries, which use non-flammable, non-toxic materials that are more sustainable and have a lower environmental impact.

How do emissions from electric car battery production compare to emissions from traditional gasoline-powered cars?

While electric car battery production can have a higher emissions impact than traditional car production, the overall emissions from electric cars are significantly lower due to their more efficient and cleaner performance on the road.

How can consumers reduce the environmental impact of electric car battery production?

Consumers can reduce the environmental impact of electric car battery production by choosing to buy cars with batteries that use responsibly sourced materials and have a lower overall environmental impact. They can also choose to recycle their batteries properly at the end of their lifespan to reduce waste.