Electric Car Battery Production: A Deep Dive into its Environmental Impact

Electric vehicles are becoming more popular as more people opt for eco-friendly modes of transportation. One of the major benefits of electric cars is that they produce significantly less pollution than traditional gas-powered cars. However, it’s important to understand the environmental impact of electric car battery production, as it plays a crucial role in their overall sustainability.

In fact, the process of manufacturing these batteries can have negative effects on both the environment and human health. This blog post will explore the environmental impact of electric car battery production, including the extraction of raw materials, manufacturing processes, and disposal methods. We’ll also touch on ways to reduce the impact and make electric cars more sustainable.

Overview of Electric Car Batteries

The production of electric car batteries has garnered attention as concerns about the environmental impact come to light. The extraction of raw materials such as lithium and cobalt for battery production has been linked to environmental degradation and human rights violations in some countries. The mining process can cause water pollution, soil contamination, deforestation, and habitat loss.

Additionally, the manufacturing of batteries requires large amounts of energy and generates greenhouse gas emissions. However, as the demand for electric vehicles increases, manufacturers are taking steps to improve the sustainability of battery production, such as sourcing materials from ethical and environmentally responsible suppliers and investing in renewable energy to power manufacturing facilities. The industry is also exploring new battery technologies with lower environmental impacts, such as solid-state batteries that use less harmful materials.

Despite these challenges, the benefits of replacing internal combustion engines with electric vehicles ultimately outweigh the environmental costs of battery production.

What Are Electric Car Batteries Made Of?

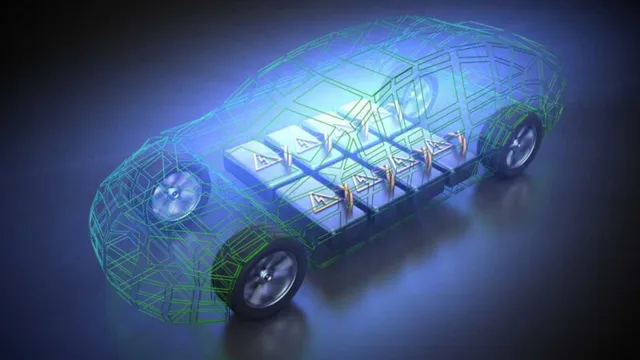

Electric car batteries are typically made up of several components, including lithium-ion cells, a battery management system, and cooling and heating systems. Lithium-ion cells are the primary energy-storage units, which are packaged together to create battery packs that can power electric cars. These cells contain electrodes made of lightweight metals like lithium and graphite, separated by an electrolyte solution.

The battery management system monitors and controls the charging and discharging of the battery pack, while the cooling and heating systems keep the battery at an optimal temperature to prolong its life. Overall, the materials used in electric car batteries are designed to be lightweight, durable, and efficient to provide enough energy to power electric cars over long distances. The demand for electric cars and their batteries is expected to increase dramatically in the coming years, as governments and consumers alike shift towards a more sustainable future.

How Are Electric Car Batteries Produced?

Electric car batteries are integral components of electric vehicles, providing them with the energy they need to run smoothly and efficiently. These batteries are typically made up of several individual cells, each containing a cathode, an anode, and an electrolyte. The cathode and anode are made from specific materials, such as lithium-ion or nickel-metal hydride, which are chosen for their ability to store and release electrical energy efficiently.

These materials are carefully processed and then assembled into the battery cells using advanced automated equipment that ensures high levels of quality and consistency. Once the cells are assembled, they are typically grouped together into larger battery modules, which are then connected to the vehicle’s electrical system. The entire battery production process is complex, but it ultimately results in reliable and high-performing batteries that power the growing number of electric vehicles on the market today.

Environmental Impacts of Electric Car Battery Production

Electric car battery production has been hailed as a major step forward in the fight against climate change, but it’s not without its environmental impacts. The production of these batteries requires the use of several rare and toxic metals, including lithium, cobalt, and nickel, which must be mined from the earth. The result is the destruction of natural habitats and ecosystems, as well as the release of harmful pollutants in water sources and the air.

Additionally, the transportation of these materials and the manufacturing process also contribute to carbon emissions, which is counterproductive to the goal of reducing carbon footprints. However, efforts are being made to improve the sustainability of battery production by implementing recycling programs and sourcing materials from responsibly managed mines. It’s clear that while electric cars have the potential to be a game-changer in reducing carbon emissions, we must also consider the environmental impacts of the production process.

Carbon Footprint of Electric Car Battery Production

Electric car battery production is often touted as a solution to carbon emissions from transportation, but the process itself does have an environmental impact. The production of electric car batteries requires a significant amount of energy, which often comes from fossil fuels. This means that the carbon footprint of electric car batteries is not zero, but it is still significantly lower than that of traditional gasoline-powered cars.

Additionally, the production of batteries can result in the extraction of raw materials like cobalt and lithium, which can have negative impacts on local ecosystems and communities. It’s important to consider the entire lifecycle of electric car batteries, from production to disposal, in order to fully understand their environmental impact. Nonetheless, the move towards electric cars is still a vital step towards reducing carbon emissions and combating climate change.

By embracing greener technologies, we can help create a cleaner, healthier future for ourselves and the planet.

Air and Water Pollution During Production

Electric car batteries are often seen as a more environmentally friendly option than traditional gasoline cars, but their production isn’t without its environmental impacts. In fact, the production of electric car batteries can result in air and water pollution. The mining of materials like lithium, cobalt, and nickel required for the batteries can release harmful chemicals and heavy metals into the air and waterways.

Additionally, the manufacturing process itself can also generate air pollution through emissions from factories and transportation. While electric car battery production may have a smaller overall carbon footprint than traditional car production, it’s important to consider the potential environmental impacts of their production as well.

Land Use for Mining and Production

As the demand for electric cars continues to grow, so does the need for lithium-ion batteries. However, the production of these batteries can have significant environmental impacts. For one, the mining of lithium and other rare earth metals requires large amounts of land use.

This can lead to deforestation and habitat destruction in areas where the minerals are mined. Additionally, the production of electric car batteries requires a lot of energy, which is often provided by fossil fuel power plants. This can result in increased greenhouse gas emissions and air pollution.

However, efforts are being made to reduce the environmental impact of battery production, such as promoting the use of renewable energy sources and improving mining practices to minimize habitat destruction. Overall, while electric cars may be more environmentally friendly on the road, it is important to consider the full life cycle of the cars, including the production of their batteries.

Efforts to Reduce the Environmental Impact of Electric Car Battery Production

Electric car battery production may have negative environmental effects, but efforts are being made to reduce these impacts. One way to achieve this is through the use of renewable energy sources in the production process. Using solar or wind energy can significantly lower greenhouse gas emissions and reduce the carbon footprint of battery production.

Another approach is the implementation of closed-loop manufacturing systems. These systems minimize waste and pollution by repurposing or recycling materials and resources during production. Additionally, switching to more sustainable materials, such as recycled metals or bio-based plastics, can lower the environmental impact of the battery production process.

As the demand for electric vehicles continues to rise, it’s essential to prioritize sustainable practices in battery production to ensure an environmentally friendly future.

Recycling and Repurposing of Electric Car Batteries

As the popularity of electric cars continues to rise, concerns have arisen about the environmental impact of the production and disposal of their batteries. To address these concerns, efforts are being made to increase recycling and repurposing of electric car batteries. Recycling can recover valuable materials such as cobalt, nickel, and lithium from used batteries, reducing the need for new mining and reducing waste.

Repurposing can also be an effective way to extend the life of these batteries for other uses such as energy storage. Such green efforts ensure that the production and disposal of electric car batteries become more sustainable in the future. Furthermore, recycling and repurposing of electric car batteries will not only create a circular economy but also provide new opportunities for green and sustainable businesses.

Improvements in Battery Production Processes

As electric cars become more popular, the demand for efficient and environmentally sustainable battery production processes has grown significantly. Many companies are working to reduce the carbon footprint of battery production, from sourcing materials like cobalt and lithium to streamlining manufacturing processes. One such effort includes reusing materials from old batteries to make new ones.

Additionally, some companies have shifted toward using renewable energy sources, such as wind and solar power, to power their factories. This not only reduces emissions but also helps to promote sustainable practices throughout the production chain. As these improvements continue to be implemented, electric cars will become a more sustainable choice for those looking to reduce their carbon footprint.

Conclusion: Balancing the Benefits and Risks of Electric Cars and Their Batteries

In conclusion, electric car battery production may not be the perfect environmental solution but it’s a step in the right direction. While there may be some negative effects on the environment, the benefits outweigh the drawbacks. After all, what good is a pristine environment when you can’t even breathe the air? With electric cars, we can reduce our reliance on fossil fuels, decrease our carbon footprint, and create a more sustainable future.

So join the EV revolution and let’s drive towards a brighter, cleaner future!”

FAQs

How does the production of electric car batteries affect the environment?

The production of electric car batteries can lead to environmental consequences such as resource depletion, emissions of greenhouse gases, and pollution from the disposal of hazardous materials.

Can the environmental impacts of electric car battery production be mitigated?

Yes, the environmental impacts of electric car battery production can be mitigated through the use of renewable energy sources, recycling of materials, and implementation of sustainable production practices.

What materials are used in the production of electric car batteries?

Electric car batteries are primarily made using metals such as lithium, cobalt, and nickel, as well as other components such as graphite and electrolytes.

Are there any alternatives to using traditional electric car batteries in order to reduce environmental impacts?

Yes, there are alternatives to traditional electric car batteries such as solid-state batteries, which are being developed to reduce the environmental impact of current battery production methods. Additionally, the use of hydrogen fuel cells is another potential alternative.