Revolutionizing the Auto Industry: Unveiling the Affordable Electric Car Battery Recycling Cost

Electric cars, while highly popular nowadays, still pose a challenge when it comes to their batteries. Specifically, the proper disposal and management of their end-of-life batteries have become an environmental and economic concern. In fact, electric car battery recycling costs are a topic that has been heavily discussed over the years, with experts trying to determine the most sustainable and cost-effective methods to dispose of and recycle these batteries.

But what exactly do these costs entail? How much does it cost to recycle an electric car battery, and who is responsible for covering these expenses? In this blog, we will delve into the intricacies of electric car battery recycling costs and explore the different factors that affect these costs.

Overview of recycling process

When it comes to recycling electric car batteries, there are various factors that can influence the overall cost of the process. The complexity of the batteries, different materials and components, and the process of dismantling them all play a role in determining the cost of recycling. In order to recycle the batteries, they must first be dismantled into different components including plastics, metals, and chemicals.

These components are then sorted and processed through various techniques such as melting, refining, and chemical processing to extract the valuable metals and materials. The recycling process can be costly due in large part to the extensive and complex nature of handling electric car batteries. However, as demand increases and technology advances, the cost of recycling may decrease making the process more economical for both consumers and businesses.

Explaining the process of recycling electric car batteries

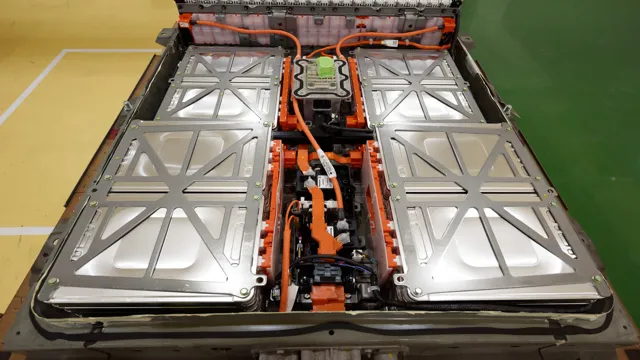

Recycling electric car batteries is essential to avoid harming the environment and make the most of the valuable materials contained in them. The recycling process starts by collecting and transporting the batteries to a specialized recycling facility. There, the batteries are dismantled, and the modules and cells are separated manually or with automated machinery.

Then, a combination of mechanical and chemical processes is used to extract valuable metals, including cobalt, nickel, and lithium. Afterward, the extracted materials are purified, sold, and used to manufacture new batteries, creating a closed-loop system and reducing the reliance on mining raw materials. Since electric car sales are increasing globally, recycling their batteries is becoming increasingly important to support sustainable growth.

Proper recycling not only eliminates waste but also reduces the environmental impact of battery manufacturing, promoting a cleaner and greener future.

Cost breakdown of battery recycling

Battery recycling is becoming increasingly important as the demand for battery-powered devices continues to rise. There are a few steps involved in the recycling process, starting with the collection and transportation of used batteries to a recycling facility. Once there, the batteries are sorted by chemistry and separated into different categories.

The recycling process varies depending on the type of battery, but typically involves breaking down the battery components to extract valuable materials such as lithium, cobalt, and nickel. These materials are then purified, refined, and sold to be used in the production of new batteries or other products. The cost breakdown of battery recycling includes transportation, labor, equipment, and the cost of processing the materials.

While the cost of recycling batteries can vary, it is generally more expensive than producing new batteries from raw materials. However, the environmental benefits of recycling outweigh the costs, as it reduces the amount of waste in landfills and conserves natural resources. Overall, the benefits of battery recycling make it a worthwhile investment for both individuals and businesses.

Environmental benefits of recycling

Electric car battery recycling cost is a crucial factor in determining the feasibility of electric vehicles in the long run. However, the benefits of recycling go beyond just cost savings. Recycling electric car batteries reduces the amount of e-waste that would otherwise end up in landfills, preventing dangerous chemicals and heavy metals from polluting the environment.

Furthermore, recycling batteries conserves natural resources by extracting valuable metals like lithium, cobalt, and nickel, which can be used to produce new batteries, reducing the need for mining. By recycling electric car batteries, we can reduce our carbon footprint and contribute to a sustainable future. So, while the upfront cost of recycling may be high, the long-term benefits of reducing e-waste and conserving resources make it a worthwhile investment.

Reducing carbon footprint with recycling

One of the most significant environmental benefits of recycling is reducing our carbon footprint. By recycling materials such as paper, plastic, and metal, we can reduce the amount of waste sent to landfills and conserve natural resources. When waste sits in landfills, it emits methane gas, a potent greenhouse gas that contributes to climate change.

Recycling also saves energy by reducing the need for new raw materials and the manufacturing process required to produce them. This not only reduces greenhouse gas emissions but also helps to conserve non-renewable resources like oil and gas. By reducing our carbon footprint through recycling, we can make a positive impact on the environment for future generations to come.

Preventing hazardous waste

Preventing hazardous waste and promoting recycling is crucial for safeguarding the environment. Recycling has several environmental benefits, including reducing the amount of waste that ends up in landfills and incinerators. When waste is properly recycled, it can be reused and repurposed, which saves valuable resources and energy.

Moreover, recycling reduces greenhouse gas emissions, which is vital in the fight against climate change. Recycling is also an excellent way to conserve natural resources, such as timber, minerals, and water, that are used in the production of goods. When we recycle, we also help to prevent the release of toxic chemicals into the environment, such as lead, mercury, and cadmium, which can pollute our soil, water, and air, causing harm to humans, animals, and plants.

Therefore, it is essential to promote and encourage recycling as much as possible to prevent hazardous waste and protect our planet.

Sustainable manufacturing

Sustainable manufacturing is quickly becoming a more pressing concern for many industries, and a significant aspect of this is recycling. There are numerous environmental benefits to recycling, including reducing the need for resource extraction and reducing landfill waste. By recycling materials, manufacturers can use less energy and water in the production process while also reducing their carbon footprint.

Plus, recycling helps to conserve natural resources, which can be a limited and precious commodity. Additionally, recycled materials are often less expensive than their non-recycled counterparts, which can provide cost savings for both manufacturers and consumers. Recycling is a critical component of sustainable manufacturing, and it is essential that companies continue to prioritize this practice to reduce their impact on the environment.

Ways to reduce recycling costs

Electric car battery recycling cost can be a significant expense for individuals and companies that are involved in the sustainable energy movement. Fortunately, there are several ways to reduce these costs without sacrificing the quality of the recycling process. One of the most effective strategies is to increase the scale of the recycling operation.

By processing a larger volume of batteries, the cost per unit can be significantly reduced. Additionally, companies can seek out partnerships with other organizations to share resources and infrastructure, which can further reduce costs. Another important consideration is the use of advanced technology and innovative recycling methods that can streamline the process and increase efficiency.

By staying up-to-date on the latest techniques and technologies, companies can remain competitive while also reducing their environmental impact. Finally, it is essential to prioritize sustainability in all aspects of the operation, from sourcing materials to disposing of waste. By adopting a holistic approach to sustainability, companies can ensure that they are doing their part to protect the planet while also minimizing costs.

Collaborating with automakers and suppliers

Collaborating with automakers and suppliers can help reduce recycling costs in various ways. One way is by designing vehicles and parts with recyclability in mind. By using materials that are easier to recycle or by creating components that can be disassembled easily, the recycling process becomes more efficient and cost-effective.

Another way is by working together to develop and standardize recycling technologies. This can help reduce the costs associated with developing and implementing new recycling processes, and can also create a more streamlined system for recycling across the industry. Collaborating can also lead to shared resources, such as recycling facilities, which can reduce costs for all parties involved.

Additionally, by collaborating on sustainability goals and initiatives, automakers and suppliers can create a more unified and effective approach to reducing waste and improving environmental performance. Collaboration is key to reducing recycling costs in the automotive industry, and we must continue to work together to create a more sustainable future.

Improving recycling technologies

Recycling technologies have come a long way in recent years, but there’s still a lot of room for improvement when it comes to reducing recycling costs. One way to do this is by increasing the efficiency of the sorting process. Currently, a lot of recyclable materials end up in landfills because of contamination, which can be costly and time-consuming to deal with.

By using new technology to improve the sorting process, however, we can reduce the amount of contamination and increase the amount of materials that can be recycled. Another way to reduce recycling costs is by investing in better transportation methods. By optimizing routes and using more efficient vehicles, we can reduce the cost of transporting recycling materials from collection sites to processing centers.

Additionally, technology can be used to improve the recycling process itself. For example, some companies are experimenting with using bacteria to break down plastics, which could offer a more sustainable and cost-effective way to recycle these materials. Overall, there are many exciting new developments in recycling technologies that could help reduce costs and make the process more efficient, and it’s important for us to continue investing in these efforts.

Future of electric car battery recycling

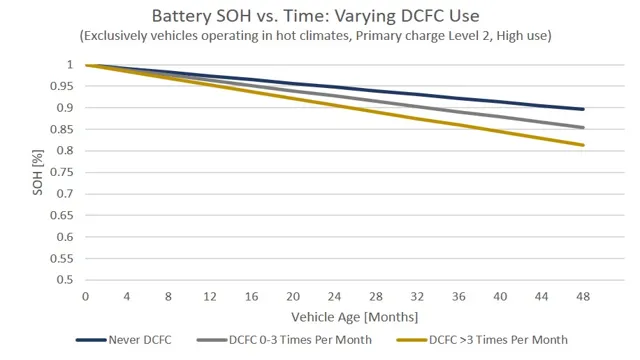

Electric car battery recycling cost is an area of concern for many stakeholders because it impacts the adoption and sustainability of electric vehicles. The good news is that recycling technology is improving, and costs are expected to decline significantly as the market matures and scales up. Currently, the cost of recycling a battery pack ranges from $1,000 to $4,000, depending on the size and chemistry of the battery.

However, these costs are expected to decrease as companies develop innovative and cost-effective recycling methods. By recycling electric car batteries, we can recover valuable materials such as lithium, cobalt, and nickel, which can be reused in new batteries. This approach reduces the environmental impact of mining and processing raw materials and conserves resources, making it a win-win for both the environment and the economy.

As electric vehicle sales continue to rise, the demand for recycling services will soar, driving innovation and cost savings for consumers.

Conclusion

In the world of electric cars, battery recycling cost is a crucial factor in determining the sustainability of this technology. While it may seem expensive at first, the long-term benefits of recycling these precious metals are undeniable. Not only does it reduce waste and pollution, but it also promotes the development of a circular economy, where old materials are transformed into new products.

So, while the cost of recycling may shock some, let’s not forget that the true cost of ignoring this issue could be felt for generations to come.”

FAQs

What is electric car battery recycling?

Electric car battery recycling is the process of extracting valuable materials from old and discarded batteries, which can then be used to create new batteries or other products.

How does electric car battery recycling help the environment?

Electric car battery recycling helps the environment because it reduces the amount of waste and toxic chemicals that end up in landfills or are released into the air or water. It also conserves natural resources by reusing valuable materials.

What is the cost of recycling an electric car battery?

The cost of recycling an electric car battery can vary depending on various factors such as the size and type of the battery, the recycling method used, and the location of the recycling facility. However, on average, it can cost between $1,000 and $3,000 to recycle a single electric car battery.

What happens to the materials extracted from electric car batteries during the recycling process?

The materials extracted from electric car batteries during the recycling process can be used to make new batteries or other products. For example, the lithium and cobalt can be extracted and used in the manufacture of new batteries or electronic devices. The nickel, copper, and other metals can be sold to manufacturers for use in other products.