The Inner Workings of Electric Car Batteries: Understanding the Structure and Powering the Future of Transportation

Electric cars are quickly gaining popularity all over the world due to their environmentally-friendly nature and long-term cost savings over gasoline-powered vehicles. And one of the major components of this modern technology is the battery. Electric car battery structure is quite different from the traditional lead-acid batteries in regular cars.

These batteries use high-capacity rechargeable lithium-ion (Li-ion) batteries that store significant amounts of energy for the car to use. They consist of multiple components, each of which plays a crucial role to ensure optimal performance and longevity of the battery. But what are these components, and how do they work together to power electric vehicles? In this blog post, we will dive deeper into the structure of electric car batteries and give you a better understanding of how they work.

We will explore the different components that make up the battery, their roles in the charging and discharging process, and how the battery’s overall structure is optimized to achieve maximum efficiency and battery life. By the end, you’ll be able to boost your knowledge of electric car battery technology, giving you a better appreciation of this exciting and fast-growing sector within the automotive industry.

Introduction to Electric Car Batteries

When it comes to electric cars, their batteries are crucial components that give them the power to run. These batteries contain several layers of different materials that work together to produce an electrical charge. The structure of an electric car battery typically consists of positive and negative electrodes, a separator, electrolyte, and a casing.

The positive electrode is usually made of metal oxides, while the negative electrode is often made of graphite or other carbon-based materials. The separator prevents the electrodes from touching each other, while the electrolyte facilitates the movement of ions between them. The casing protects the battery and secures its components in place.

Overall, the intricate structure of an electric car battery enables it to store and release energy efficiently, making it a crucial part of the electric vehicle experience.

What is an Electric Car Battery?

The electric car battery is the power source that makes electric vehicles (EVs) run. These batteries are responsible for storing the energy generated by the vehicle’s electric motor and converting it into power that can be used to move the car forward. The batteries are made up of a series of cells, each of which contains a positively charged electrode, a negatively charged electrode, and an electrolyte.

The electrolyte is typically a type of liquid or gel that facilitates the movement of ions between the electrodes. These batteries can be charged using a home charging station, public charging stations, or fast-charging stations, depending on the size and type of battery. The advancements in battery technology have allowed EVs to drive further and faster than ever before, making them a more practical and viable option for many drivers.

How does an Electric Car Battery Work?

Electric Car Battery Electric car batteries are the heart of any electric car. They are responsible for supplying power to the electric motor and all the other electrical components of the vehicle. These batteries are designed to store energy and convert it into electrical power when needed.

The battery is made up of several cells, each of which contains a positive and negative electrode, separated by an electrolyte. The most common type of battery used in electric cars is the lithium-ion battery. These batteries are lightweight, long-lasting, and have a high energy density, which makes them ideal for use in electric vehicles.

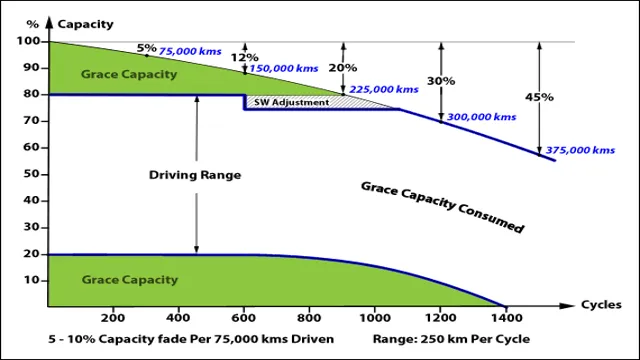

The battery life of an electric car can vary depending on several factors, including the size of the battery, temperature, and driving conditions. Overall, electric car batteries are a crucial part of the electric car ecosystem, and their technology is constantly evolving to make electric cars more efficient and reliable.

Types of Electric Car Batteries

There are several types of electric car batteries that are used in the automotive industry. Lithium-ion batteries are the most common type of electric car battery structure due to their high energy density and reliability. They are lightweight and provide a long range which makes them ideal for electric vehicles.

However, sodium-nickel chloride batteries are also becoming popular as they provide high electrical efficiency and have a low environmental impact. Nickel-metal hydride batteries were once widely used, but are losing popularity due to their low energy density. Another type of battery is the solid-state battery, which is still in development but is expected to offer even higher energy density and faster charging times.

The choice of battery used in an electric car depends on various factors such as vehicle type, range, and cost-effectiveness. Overall, the development of new and improved batteries for electric cars is essential for the growth of the electric vehicle industry.

Lithium-Ion Batteries

Lithium-ion batteries are the most popular type of battery used in electric cars due to their high energy density, long life span, and low maintenance requirements. However, there are a few different types of lithium-ion batteries that can be used in electric cars. The most common type is the nickel-cobalt-aluminum (NCA) battery, which is used in Tesla’s Model S and Model X cars.

Another type is the nickel-manganese-cobalt (NMC) battery, which is commonly used in the BMW i3 and Nissan Leaf. Finally, there is the lithium-iron-phosphate (LFP) battery, which is used in some of the more affordable electric cars such as the BYD e Each type of battery has its own advantages and disadvantages, so it is important for car manufacturers to choose the right type of battery for their specific model.

Ultimately, the success of electric cars will depend on the continued development and improvement of these battery technologies.

Nickel-Metal Hydride (NiMH) Batteries

When it comes to choosing the right battery for an electric car, several factors come into play. One of them is the battery’s chemistry. One type of battery that’s commonly used in electric cars is nickel-metal hydride (NiMH) batteries.

They are known for their high energy density, making them a great option for smaller and lighter electric cars. NiMH batteries are also more affordable than their lithium-ion counterparts, making them an attractive option for budget-conscious buyers. However, they do have their downsides.

They are heavier and bulkier than lithium-ion batteries, which means they take up more space in the car and add to its overall weight. Despite this, NiMH batteries remain a popular choice for electric car manufacturers and consumers alike, and their usage is expected to continue for years to come.

Solid-State Batteries

Solid-State Batteries Solid-state batteries are rapidly gaining traction as an alternative solution to the conventional lithium-ion batteries that power most electric cars on the road today. These batteries use solid electrolytes instead of liquid ones, which can improve safety, higher energy density, and reduce the risk of fire. One type of solid-state battery, the lithium-polymer battery, is known for its lightweight and flexible form, making it an ideal option for fitting into irregularly-shaped battery packs required by some electric vehicles.

Another type of solid-state battery is the solid-state lithium-ion battery, which offers a high power density, faster recharge times, and a longer lifespan. Overall, solid-state batteries have the potential to revolutionize the way electric cars are powered, offering greater safety, improved performance, and longer ranges for drivers.

Battery Pack Components

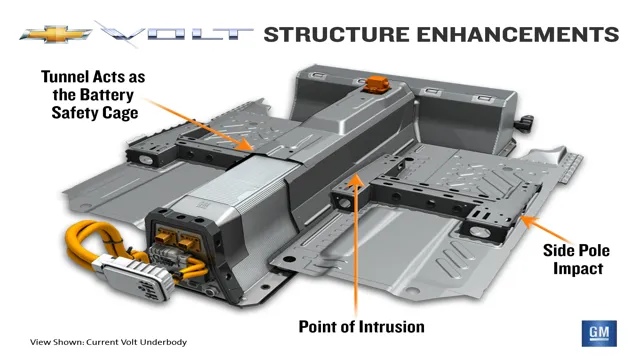

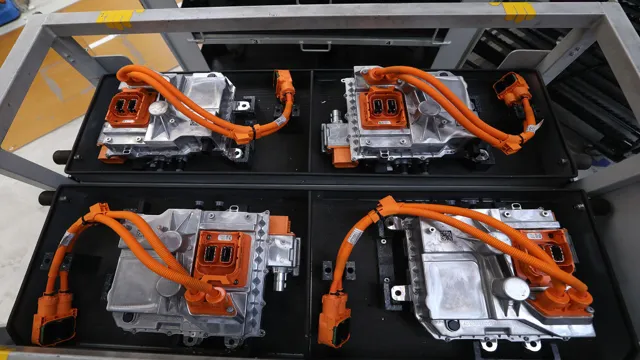

The electric car battery structure is made up of several components that work together to provide power to the vehicle. The most important component is the battery pack, which contains multiple modules, each housing a group of battery cells. These cells are connected in series and parallel, depending on the required voltage and capacity.

Another crucial component is the battery management system, which monitors and controls the charging and discharging of the battery pack, ensuring its optimal performance and safety. Additionally, the cooling system plays a significant role in dissipating the heat generated by the batteries, avoiding damage or failure. The electric car battery structure also includes the power electronics, which manage the flow of electricity from the battery pack to the electric motor.

The charging system is another essential component that enables the battery to be charged from an external power source, such as a public charging station or a home wall box. All these components work in harmony to create a reliable and efficient electric car battery.

Battery Cells

When it comes to battery packs, the battery cells are a crucial component. These cells are the actual power source in the battery pack and are responsible for storing and releasing energy. There are many types of battery cells available in the market, including lithium-ion, nickel-cadmium, and lead-acid cells.

Lithium-ion cells, in particular, are currently the most popular due to their high energy density, low self-discharge rate, and long cycle life. However, each type of battery cell has its own unique properties and advantages, making it important to choose the right type for the specific application. Additionally, battery pack designers must carefully consider factors such as voltage, capacity, and temperature requirements when selecting battery cells to ensure optimal performance and safety.

Ultimately, the right combination of battery cells can result in a battery pack that delivers efficient, reliable, and long-lasting power.

Battery Management System (BMS)

A crucial component of any battery pack is the Battery Management System (BMS), which ensures the safe and efficient operation of the battery system. The BMS is responsible for monitoring the battery’s performance, including its state of charge, temperature, and voltage, to prevent overcharging and over-discharging. It also helps to balance the cell voltages to ensure that the battery pack operates at its maximum capacity.

The BMS also acts as a safety system, disconnecting the battery pack from the rest of the system and activating warning alarms in case of potential safety hazards. Choosing the right BMS is critical to ensure the long-term performance and safety of the battery pack.

Cooling System

The battery pack is one of the most important components of an electric vehicle. It stores the energy that powers the vehicle’s electric motor, allowing it to move efficiently without producing harmful emissions. However, it is essential to keep the battery pack cool to ensure that it operates correctly.

The cooling system is a crucial part of the battery pack, and it works by regulating the temperature to prevent overheating. The cooling system uses a combination of air and liquid cooling to prevent the temperature from rising too high. If the battery pack gets too hot, it can cause significant damage and reduce the range of the vehicle.

Therefore, proper cooling is an essential part of maintaining the battery pack’s function and lifespan. The battery pack’s health can also be monitored through a dedicated system that tracks its performance and helps identify any potential issues. Overall, maintaining the battery pack’s cooling system is a crucial part of ensuring the electric vehicle’s longevity and efficiency.

Charging an Electric Car Battery

When it comes to charging an electric car battery, it’s important to understand the structure of the battery itself. Electric car batteries typically have several cells connected in series, which work together to provide the power needed to drive the car. Each cell is made up of electrodes, a separator, and electrolyte.

The electrodes are made of different materials, with the positive electrode usually made of lithium cobalt oxide and the negative electrode made of graphite. The separator in the middle helps prevent the electrodes from coming into contact, which can cause a short circuit. When it comes time to charge the battery, the process involves using an external power source to add electrons back to the battery’s cells.

This causes the lithium ions in the battery’s electrodes to move from the positive electrode to the negative electrode, where they’re stored until it’s time to use the battery’s power again. By understanding the structure of an electric car battery, you can better understand how to charge it and keep it running smoothly.

Level 1 Charging

Level 1 charging is the most basic form of charging an electric car battery. It refers to using a standard household electrical outlet to charge the car at a rate of around 4-5 miles of range per hour. While this charging method is slow and not ideal for long-distance travel, it can be sufficient for those who have a short commute or only need to charge their car overnight.

It’s important to note that Level 1 charging requires a standard 120-volt outlet, which may not be easily accessible for everyone. Additionally, it’s recommended to have a dedicated circuit for Level 1 charging to avoid tripping any breakers or causing electrical issues. Overall, while Level 1 charging may not be the most efficient charging method, it remains a popular option for many electric car owners.

Level 2 Charging

Level 2 charging is one of the most popular ways to charge an electric car battery. It’s quite efficient, and you can easily find level 2 charging stations in many public locations such as malls, parking lots, and gas stations. Level 2 charging requires a charging station that provides power of 240 volts, which can charge a typical electric car battery from zero to full in about 4-8 hours, depending on the battery pack size.

This charging level is usually recommended for a daily use, especially for people who drive long distances regularly. Using level 2 chargers is hassle-free since they are easy to use, with just a simple plug-in process, and they come with an app or scanner to initiate the charging process. You can also install a home charging station, so you can have the convenience of charging your electric car at home, overnight, or while you’re not using it.

Conclusion

In conclusion, the structure of an electric car battery is a technological marvel that has revolutionized the automotive industry. Its intricate design and composition ensure maximum efficiency and power storage, allowing for longer and more sustainable drives. It’s like having a sophisticated energy-packed sandwich, but instead of bread and meat, it’s made up of layers of electrodes and electrolytes that work together seamlessly to deliver a strong and reliable charge.

So, the next time you see an electric car zooming by, remember that the real magic lies in the battery tucked away inside.”

FAQs

What is the structure of an electric car battery?

An electric car battery typically consists of several individual cells, which are connected in a series or parallel configuration to provide the desired voltage and capacity.

What materials are commonly used to make electric car batteries?

Lithium-ion batteries are the most common type of electric car battery and are typically made from a combination of carbon, lithium, and metal oxide.

How long does an electric car battery last before it needs to be replaced?

The lifespan of an electric car battery depends on several factors, including the quality of the battery, how frequently it is used, and how well it is maintained. Generally speaking, most electric car batteries can last anywhere from 5-10 years.

Can electric car batteries be recycled?

Yes, electric car batteries can be recycled, and many automotive manufacturers have established programs to facilitate the recycling of old batteries. This not only helps to reduce waste and conserve resources but can also provide a source of valuable materials for new battery production.