Powering the Future: Navigating the Electric Car Battery Supply Chain

The electric car revolution is gaining momentum, with eco-conscious drivers opting for zero-emission vehicles for transportation. The rise in demand for electric vehicles means the batteries powering them are in high demand. However, the question of the electric car battery supply chain remains somewhat murky.

How is the supply chain established, and what are the potential implications of increasing demand for batteries? This blog will explore the supply chain of electric car batteries and the possible challenges of meeting future demand.

Overview of Electric Car Battery Supply Chain

The electric car battery supply chain is a complex and ever-evolving network of manufacturers, suppliers, and distributors that work together to produce and deliver the batteries that power electric vehicles. At the heart of this supply chain are the battery manufacturers themselves, who use specialized equipment and processes to create high-quality, reliable batteries that meet the demands of the automotive industry. These batteries are then sold to automotive manufacturers, who install them in their electric vehicles before sending them to dealerships and customers around the world.

Along the way, there are many other players involved in the supply chain, including raw materials suppliers, logistics providers, and recycling companies that help to ensure that these batteries are produced and disposed of in an environmentally responsible way. With the growing popularity of electric vehicles, the electric car battery supply chain is becoming more important than ever, and is constantly evolving to meet the demands of this fast-moving industry.

Key stakeholders

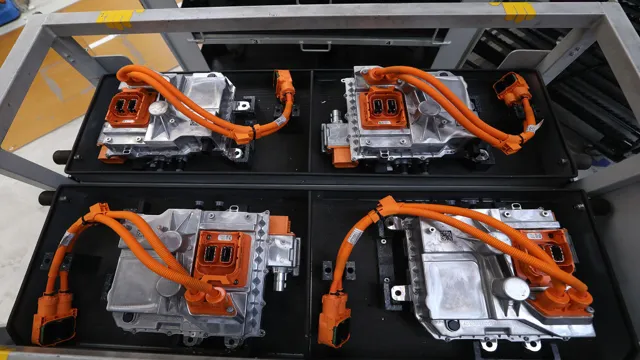

One of the key stakeholders in the electric car battery supply chain is the automaker. They are responsible for the design and production of the electric vehicles themselves, which are powered by these batteries. Automakers work closely with battery manufacturers to ensure that the batteries meet the precise specifications required for their vehicles, including size, weight, and charging capabilities.

Another key stakeholder is the battery manufacturer, who is responsible for designing, developing, and producing the batteries. They work with raw material suppliers to ensure a reliable supply of materials such as nickel, cobalt, and lithium. The third key stakeholder is the mining and extraction industry, which is responsible for extracting and refining these raw materials.

These industries are essential for the success of the electric car battery supply chain as they play a vital role in ensuring the availability of materials. Finally, governments and regulatory bodies are critical stakeholders as they set policies and regulations that drive the growth and adoption of electric vehicles. They may provide incentives and subsidies to encourage the use of electric cars and promote investment in electric car battery manufacturing.

Overall, collaboration and cooperation among these stakeholders are essential to ensure a reliable and sustainable supply chain for electric car batteries.

Battery materials and production

Electric car battery supply chain The electric car battery supply chain consists of several components, including the raw materials used to create the batteries, the battery production process, and the distribution of the final product to car manufacturers. The raw materials used to create electric car batteries include lithium, cobalt, nickel, and manganese, which are often found in mines around the world. Once mined, these materials are then processed and converted into battery components in specialized factories.

After production, the batteries are transported to car manufacturers, who then incorporate them into their vehicles. The electric car battery supply chain has become increasingly important as more and more car manufacturers switch to electric vehicles to reduce emissions and mitigate the effects of climate change. Ensuring a stable and sustainable supply chain for the raw materials used in these batteries will be crucial going forward as the demand for electric cars continues to grow.

Key Challenges in Electric Car Battery Supply Chain

The emergence of electric cars has brought about a surge in demand for electric car batteries, thereby creating new challenges and opportunities in the electric car battery supply chain. One of the key challenges is the need to enhance the production of affordable and efficient batteries, capable of providing long-lasting performance and durability. The production of lithium-ion batteries, which are commonly used in electric car batteries, is capital-intensive, and requires massive investments in R&D, raw materials, and production facilities.

Another challenge relates to the sourcing of raw materials used in the batteries, such as cobalt, lithium, and nickel, among others. These materials are scarce, and their mining and manufacturing can have adverse environmental and social impacts. Additionally, the current state of infrastructure necessitates substantial investment in charging stations, which is another critical aspect in ensuring a sustainable future for electric car battery production and usage.

Overall, addressing these challenges and opportunities in the electric car battery supply chain necessitates collaboration and innovation across the entire value chain, governments, and other stakeholders.

Sustainability challenges

The growing popularity of electric vehicles has raised concerns about the sustainability of their battery supply chain. The key challenge lies in sourcing sustainable materials for the production of batteries. The mining of minerals such as cobalt, lithium, and nickel, which are essential components of electric car batteries, poses environmental and social risks.

The mining and refining processes require large amounts of water and energy and can generate toxic waste, leading to soil and water pollution. Additionally, the mining industry has been linked to human rights violations, including child labor and exploitation of indigenous communities. The increasing demand for electric vehicles has put pressure on supply chains to ensure that materials are ethically sourced and that the production process is environmentally sustainable.

Companies must work towards establishing transparent and responsible supply chains, using sustainable materials, and minimizing the use of hazardous chemicals to ensure a sustainable future for electric car batteries.

Resource scarcity challenges

Resource scarcity continues to pose significant challenges for the electric car battery supply chain. One of the key challenges is the limited availability of raw materials needed to manufacture lithium-ion batteries. The demand for these materials, such as cobalt and nickel, has soared in recent years, leading to skyrocketing prices and concerns over the ethical sourcing of these materials.

In addition to resource scarcity, another major challenge is the supply chain’s complexity, as the batteries require multiple components from different suppliers across the globe. This complexity can lead to disruptions in the supply chain, causing delays and uncertainty for automakers. Furthermore, with the production of electric cars ramping up quickly, the supply of batteries is struggling to keep up with demand, leading to another challenge of building enough battery production facilities to meet the needs of the industry.

These challenges in the electric car battery supply chain highlight the need for sustainable solutions to ensure that the production of electric vehicles remains viable and ethical in the long run.

Supply and demand challenges

When it comes to the electric car battery supply chain, it’s not all smooth sailing. One of the key challenges facing this industry is the issue of supply and demand. As more and more consumers opt for electric vehicles, the demand for batteries is skyrocketing.

This has put pressure on manufacturers to ramp up production, but there is only so much they can do. In addition to this, there are also concerns around the availability of raw materials such as lithium, cobalt, and nickel. With so much uncertainty around the supply chain, it can be difficult for companies to plan ahead and ensure they have enough batteries to meet demand.

As a result, we may see longer wait times for electric cars and higher prices for batteries in the years to come. It’s clear that the electric car industry has a long way to go before it can overcome all of these challenges, but with innovation and collaboration, there is hope for a brighter, sustainable future.

Innovations and Trends in Electric Car Battery Supply Chain

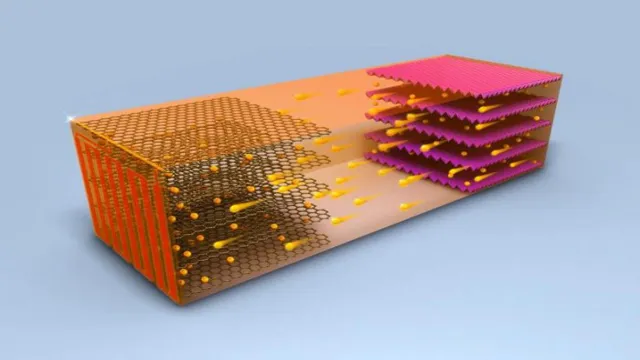

The electric car battery supply chain is ripe for innovation and advancements. With the rise in demand for electric vehicles, there’s a need to produce high-quality batteries that are long-lasting and sustainable. One significant trend in the electric car battery supply chain is the shift towards solid-state batteries.

These batteries show potential for higher energy density, longer life cycles, and improved safety. Additionally, there’s a ramp-up in investment in battery recycling and closed-loop systems to make the supply chain more sustainable. The use of artificial intelligence and big data is also helping to optimize the battery production process, from raw material sourcing to final assembly.

Furthermore, collaborations between automakers and battery manufacturers are becoming more commonplace, leading to a smoother and more efficient supply chain. The electric car battery supply chain is evolving rapidly, and these innovations and trends are paving the way for a brighter and more sustainable future.

Circular economy initiatives

Circular economy initiatives As the demand for electric cars continues to rise, so does the demand for electric car batteries. This has led to an increase in innovation and trends in the electric car battery supply chain. Companies are now focusing on circular economy initiatives, leading to a shift in the way batteries are produced and disposed of.

A circular economy is an economic system aimed at eliminating waste and the continuous use of resources. One such initiative is the development of biodegradable batteries, which can be easily disposed of without harming the environment. Another initiative is the use of recycled battery materials, which reduces the amount of waste generated.

Companies are also developing methods to increase the lifespan of batteries, such as battery refurbishing and battery swapping programs. These circular economy initiatives not only benefit the environment but also reduce costs for consumers and companies. As we continue to shift towards a sustainable future, circular economy initiatives will play a crucial role in ensuring the longevity of our planet.

Emerging technologies

Electric car batteries are an essential component of the electric vehicle supply chain. Innovative breakthroughs and trends in this critical technology are transforming the vehicle industry. The development of electric car batteries is rapidly advancing towards higher performance and safety while reducing their carbon footprint.

The use of recycled materials and sustainable manufacturing processes in battery production is an emerging trend in the electric car industry. This sustainable approach will help reduce carbon emissions, increase supply chain stability, and minimize environmental impacts. The use of solid-state batteries is also becoming more prevalent, and it is anticipated that they will replace the lithium-ion batteries that are commonly used in electric vehicles.

These batteries are compact, safe, and have more extended battery life, increasing their efficiency. The future of electric vehicle batteries promises to be advanced, sustainable, and environmentally friendly. As the electric vehicle market grows, so will the demand for innovative and advanced battery technologies, ensuring the potential for a continued explosion of innovation.

The Future of Electric Car Battery Supply Chain

The electric car battery supply chain is rapidly evolving, and with the increasing demand for electric vehicles, the need for batteries is growing at an unprecedented rate. The future of this supply chain looks bright, as many companies are investing in research and development to improve battery technology. Some of these improvements include longer-lasting batteries, faster charging times, and increased energy density.

In addition to these advancements, there is also a push towards sustainable materials and recycling, as the production of batteries can result in significant environmental impact. Overall, the future of the electric car battery supply chain is full of promise and potential, and we can expect to see many exciting new developments in the coming years.

Conclusion

In conclusion, the electric car battery supply chain is an intricate web of interdependent components, much like the intricate system within an electric car. From the sourcing of raw materials to the manufacturing of batteries, and the installation of these batteries into cars, every step is crucial in bringing these eco-friendly vehicles to market. As the demand for electric cars continues to grow, so too will the importance of securing a sustainable supply chain for electric car batteries.

So, next time you hop in an electric car, take a moment to appreciate the complex journey that brought it to life, and the role that each part of the supply chain played in creating this cleaner, greener transportation solution.”

FAQs

What is an electric car battery supply chain?

An electric car battery supply chain refers to the process of producing and distributing batteries used in electric vehicles, from initial component manufacturing to final assembly.

What are the major components of an electric car battery supply chain?

The major components of an electric car battery supply chain include raw materials like lithium, cobalt, and nickel; battery component manufacturers; battery cell producers; battery pack assemblers; and car manufacturers.

What are some of the challenges in the electric car battery supply chain?

Some of the challenges in the electric car battery supply chain include ensuring a steady and affordable supply of raw materials, overcoming technical hurdles in manufacturing and assembly processes, and addressing ethical concerns around the use of child labor in mining operations.

How is the electric car battery supply chain impacting the auto industry?

The electric car battery supply chain is disrupting traditional auto industry supply chains by creating new partnerships and business models focused on electric vehicle production. It is also driving technological innovation and investment in new battery technologies.