The Race for Cobalt: Why Electric Car Makers are Stockpiling Funds to Secure Battery Supply Chains

If you’re an electric car maker, listen up! It’s time to be cautious as cobalt supply becomes increasingly scarce. While cobalt may not be a household name, it’s a vital ingredient in the production of the lithium-ion batteries that power electric vehicles. Without it, the electric car industry could come grinding to a halt.

And while some companies have already taken action to secure their cobalt supply, others are lagging behind. Funds, on the other hand, are stockpiling cobalt as they prepare for the potential shortage. So, what does this mean for electric car manufacturers? Are they in danger of being left behind? Let’s explore.

What is Cobalt and Why is it Important for Electric Cars?

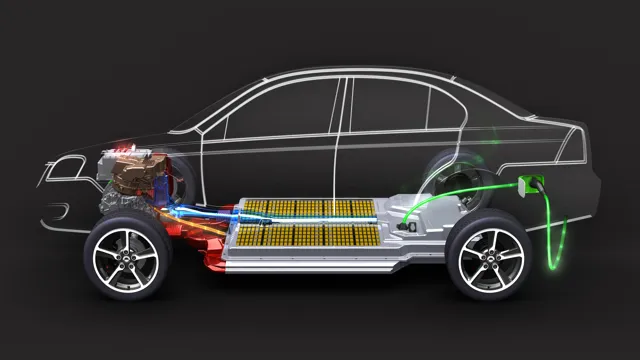

With the rise in popularity of electric cars, manufacturers are ramping up production to meet the demands of consumers. However, electric car makers are on battery alert because funds are stockpiling cobalt, a critical mineral used in lithium-ion batteries. Cobalt is essential for electric vehicles as it helps provide stability and durability to the batteries, allowing them to store and release power efficiently.

Unfortunately, the increasing demand for cobalt has led to concerns about its sustainability and ethical sourcing. Mining cobalt can have devastating environmental impacts and can be linked to child labor in certain regions. Thus, it is crucial for the industry to create a sustainable and ethical supply chain for cobalt to ensure the longevity of the electric car market.

Cobalt: A Key Ingredient in EV Batteries

Cobalt is a vital material in the production of electric vehicle batteries, accounting for up to 60% of the battery’s cost and weight. This silvery-gray metal plays a significant role in enhancing the battery’s durability and energy density. Cobalt is an essential element because it helps stabilize the structure of the battery and improve its performance by increasing the amount of energy it can store.

It also enhances the battery’s lifespan, allowing it to last for more extended periods before needing to be replaced. However, the use of cobalt also has its downside, as it is a rare and expensive material that presents ethical and environmental issues during the extraction process. With the increasing demand for electric vehicles, alternative materials are being researched to mitigate the dependence on cobalt and reduce its environmental impact.

Why the Stockpiling of Cobalt Matters

Cobalt is a critical component of lithium-ion batteries and is utilized in electronic devices such as smartphones, laptops, and primarily electric cars. The stockpiling of cobalt is a major concern because the supply chain is constrained and production is limited to a few countries. The demand for electric cars is increasing, and as a result, the demand for cobalt is also soaring.

Moreover, cobalt is mined primarily in the Democratic Republic of Congo, which is a politically unstable region. The mining of cobalt is fraught with issues such as the use of child labor and environmental degradation. Despite the challenges, the auto industry is working towards reducing the amount of cobalt used in batteries and to find alternative sources that are more sustainable, ethical, and affordable.

In conclusion, cobalt is a critical mineral that plays a vital role in the production of electric cars, and its stockpiling is a crucial issue that needs immediate attention.

Who’s Stockpiling Cobalt and Why?

Electric car makers are on high alert due to recent reports about funds stockpiling cobalt. Cobalt is a critical component used in lithium-ion batteries, which power electric vehicles. With the surge in demand for electric cars, there is a growing concern that cobalt supplies may not be able to keep up.

Thus, investors are looking to secure their own supplies by storing cobalt. Reports suggest that some funds are hoarding significant amounts of the mineral, leading to fears of a shortage in the future. As a result, electric car manufacturers are closely monitoring the situation and looking into alternatives to reduce their dependence on cobalt.

While this development may leave car manufacturers with fewer options, it also highlights the growing need for sustainable electric car battery production.

Investors Flock to Cobalt Amid Growing Demand for EVs

Investors are turning their attention to cobalt as demand for electric vehicles (EVs) continues to surge. Cobalt is a critical component in the batteries used to power EVs, making it an essential commodity in the industry. Companies including Apple and Tesla have been reported to be stockpiling cobalt to ensure their supply chain remains strong.

However, the increased demand for cobalt is also creating concerns over supply chain ethics and labor practices. Many of the world’s cobalt reserves are in the Democratic Republic of Congo, where allegations of child labor and unethical mining practices have surfaced. As a result, there is a growing push for companies to ensure their cobalt supply chains are ethical and sustainable.

As the EV industry grows, so too will the demand for cobalt, making ethical sourcing a critical factor for manufacturers in the years ahead.

Cobalt Price Rally Fuels Stockpiling by Funds and Battery Makers

Cobalt The rise in cobalt prices is causing many funds and battery makers to start stockpiling this precious metal. The reason for this stockpiling is that cobalt is a key component in many rechargeable lithium-ion batteries and demand is high as the world moves towards more sustainable energy sources. The current rally in cobalt prices is being largely driven by a surge in electric car manufacturing, with cobalt being an essential element in the batteries that power these vehicles.

Funds and battery makers are taking advantage of this surge in demand by buying up as much cobalt as they can, with the aim of profiting from the price increase as demand continues to outstrip supply. While this strategy can be risky due to the volatile nature of commodity prices, many investors see cobalt as a promising investment due to its strategic position in the renewable energy supply chain. Whether you are an investor or simply interested in the future of renewable energy, it’s worth keeping a close eye on the cobalt market in the coming months.

Major Automakers Eyeing Long-Term Cobalt Supply Deals

Cobalt has always been an important element for the automotive and tech industries. However, in recent years, major automakers have been eyeing long-term cobalt supply deals, and the reason isn’t difficult to guess: electric vehicles. Cobalt is a crucial component in the production of lithium-ion batteries, which are used in EVs.

With more and more car manufacturers launching EVs, the demand for cobalt has surged. In fact, some estimates suggest that cobalt consumption could increase by up to 60% in the next five years. To avoid potential supply chain disruptions, major automakers like BMW and Volkswagen are stockpiling cobalt.

This helps them ensure a steady supply of the element, reduce dependence on the volatile spot market, and secure favorable prices. Besides stockpiling, some carmakers are also investing in mining projects, forging long-term supply contracts, and exploring alternative chemistries that use less cobalt. Overall, the trend suggests that cobalt will remain a critical element for the auto industry for years to come.

What Does this Mean for Electric Car Manufacturers?

Electric car manufacturers need to be on high alert due to the recent stockpiling of cobalt by funds. Cobalt is an essential element in the production of lithium-ion batteries, which are used in most electric cars. The increased demand for electric vehicles has resulted in a surge in the price of cobalt, leading to a rush among investment firms to secure supplies.

Electric vehicle makers need to be cautious because if they don’t secure access to cobalt supplies, it could lead to a shortage of batteries, delaying production schedules and ultimately impacting their bottom line. Manufacturers must also consider the ethical implications of using cobalt, as it is often mined in unregulated and unsafe conditions in countries like the Democratic Republic of Congo. Overall, the race to secure cobalt will only increase in the coming years, and electric car manufacturers need to ensure they have the necessary access to this precious resource to continue driving the future of green transportation.

Rising Cobalt Prices Could Cause Disruption in EV Production

As cobalt prices continue to rise, electric vehicle manufacturers may be facing some potential disruptions in their production processes. Cobalt is a crucial metal used in the manufacturing of EV batteries, and with its prices skyrocketing, the implications could be dire. To put things into context, the price of cobalt has tripled over the last two years, and experts predict that it might continue to rise.

This disparity could hit smaller electric vehicle manufacturers the hardest, as they may not have the leverage to negotiate better prices with cobalt suppliers. On the other hand, bigger manufacturers with established relationships with suppliers may be better positioned to weather the rising prices. It will be interesting to see how the industry will adapt to this challenge, and whether alternative materials will be considered in the production of EV batteries.

Ultimately, the rising cobalt prices could lead to higher prices for electric cars, which in turn may dampen demand.

Alternative Battery Technologies Could Help Reduce Cobalt Dependency

With the rise of electric cars, alternative battery technologies could reduce dependency on cobalt. This shift can have major implications for electric car manufacturers who rely on cobalt as a key ingredient in the production of lithium-ion batteries. Cobalt’s high cost and the ethical concerns surrounding its mining practices make it a challenging resource for manufacturers to sustainably source.

Alternative battery technologies such as solid-state batteries, sodium-ion batteries, and zinc-air batteries can provide more affordable, ethical, and eco-friendly solutions. Manufacturers can reduce the use of cobalt in their production processes without sacrificing battery performance, making it a win-win for both manufacturers and consumers. As the market continues to demand more environmentally friendly solutions, these alternative battery technologies may become the norm and reduce our dependency on cobalt.

Conclusion: The Importance of Cobalt for the EV Industry

In the race to develop sustainable electric vehicles, cobalt has become the prized resource that is keeping car makers on battery alert. With funds stockpiling cobalt, manufacturers are scrambling to secure a sustainable supply of this valuable metal, which is essential for producing high-performance batteries. As the world shifts towards more eco-friendly transportation options, the importance of cobalt is only going to increase.

It’s time for car makers to buckle up and get serious about investing in clean energy solutions – because the future of our planet depends on it!”

FAQs

Why are electric car makers on battery alert?

Electric car makers are on battery alert because they rely heavily on cobalt, which is a crucial ingredient in the production of batteries.

What is the significance of cobalt in battery production?

Cobalt is an essential element that is used in the cathode of lithium-ion batteries, which power most electric vehicles. It provides stability and gives batteries a longer life span.

Why are funds stockpiling cobalt?

Funds are stockpiling cobalt due to the growing demand for electric vehicles and the limited supply of this precious metal. As a result, the prices of cobalt have risen significantly, making it an attractive investment opportunity.

What are the implications of the shortage of cobalt for the electric car industry?

The shortage of cobalt could lead to a disruption in the production of electric vehicles, causing delays and potentially higher costs. This could slow down the adoption of electric cars, which could have negative consequences for the environment and the economy.