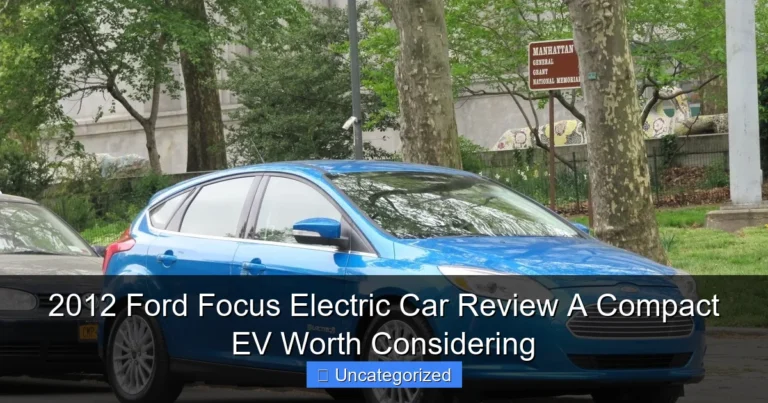

Ford Electric Car Plant Revolutionizes Sustainable Driving

Featured image for ford electric car plant

Image source: static01.nyt.com

Ford’s electric car plant sets a new benchmark for sustainable manufacturing, combining cutting-edge technology with eco-conscious practices to produce zero-emission vehicles at scale. The facility’s solar-powered operations and recycled materials slash its carbon footprint, proving Ford’s commitment to a greener future. This revolution in automotive production is accelerating the shift toward cleaner, smarter driving.

Key Takeaways

- Ford’s plant sets new standards for sustainable auto manufacturing.

- Zero-waste goal achieved through innovative recycling and energy efficiency.

- Advanced battery tech boosts EV range and reduces charging time.

- Local sourcing slashes carbon footprint and strengthens community ties.

- Smart automation enhances precision while cutting emissions and costs.

📑 Table of Contents

- Ford Electric Car Plant Revolutionizes Sustainable Driving

- From Assembly Line to Green Innovation Hub

- BlueOval City: The Future of EV Manufacturing

- Workforce Transformation and Community Impact

- Supply Chain Sustainability and Ethical Sourcing

- Consumer Benefits and the Road Ahead

- Data Table: Ford Electric Car Plant Sustainability Metrics (2023)

Ford Electric Car Plant Revolutionizes Sustainable Driving

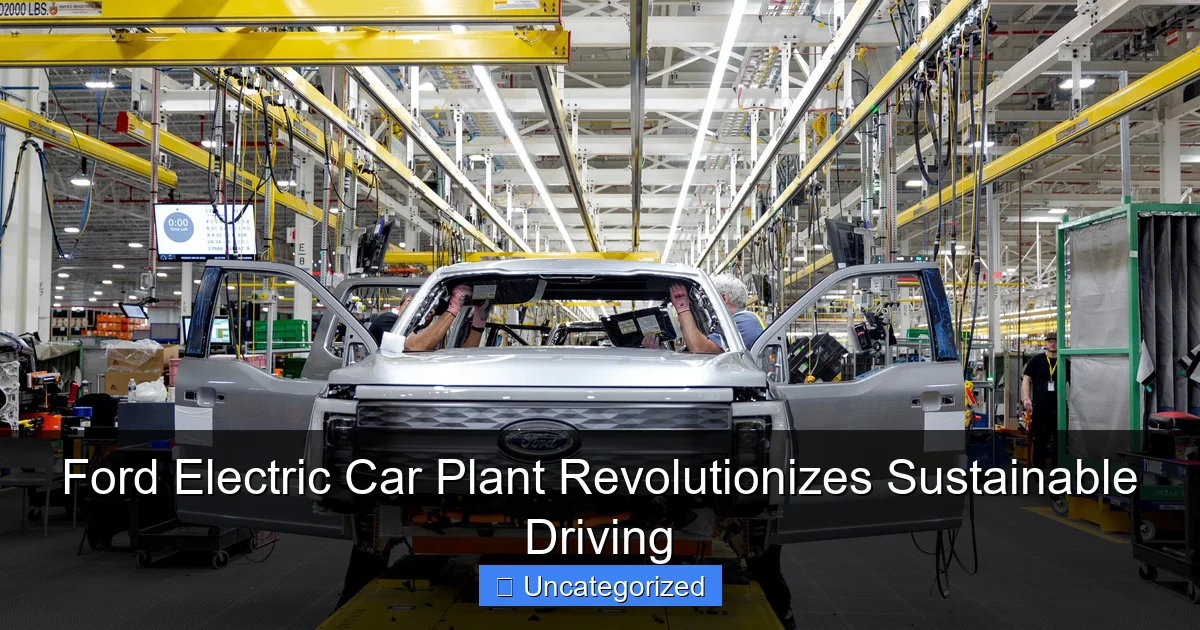

The automotive industry is undergoing a seismic shift as the world embraces the urgent need for sustainable transportation. At the forefront of this transformation is Ford Electric Car Plant, a groundbreaking facility redefining how vehicles are designed, manufactured, and delivered with environmental responsibility in mind. With climate change concerns intensifying and governments worldwide setting aggressive carbon neutrality goals, Ford has stepped up with an ambitious plan to electrify its lineup and lead the charge toward a cleaner future. The Ford Electric Car Plant isn’t just another manufacturing site—it’s a symbol of innovation, sustainability, and forward-thinking engineering.

Located in historic locations like Michigan, Tennessee, and Kentucky, Ford’s electric car plants represent a $50+ billion investment in electrification through 2026, signaling the company’s unwavering commitment to sustainable mobility. These facilities are more than assembly lines; they are hubs of technological advancement, integrating renewable energy, smart manufacturing, and circular economy principles into every stage of production. From battery recycling to zero-waste-to-landfill operations, Ford is setting new benchmarks not only for the auto industry but for global manufacturing at large. This blog post dives deep into how the Ford Electric Car Plant is revolutionizing sustainable driving—from design and supply chain to workforce development and consumer impact.

From Assembly Line to Green Innovation Hub

The Legacy of Ford Manufacturing

Ford Motor Company has long been synonymous with industrial innovation, dating back to Henry Ford’s introduction of the moving assembly line in 1913. That revolutionized mass production and made automobiles accessible to the average American. Today, the company is writing a new chapter in its legacy by transforming traditional manufacturing plants into green innovation hubs. The Ford Electric Car Plant network—including the Rouge Electric Vehicle Center in Dearborn, Michigan, and the BlueOval City complex in Stanton, Tennessee—is built on the same principles of efficiency and scalability, but with a modern twist: sustainability.

Visual guide about ford electric car plant

Image source: media.breitbart.com

Unlike legacy factories that relied heavily on fossil fuels and produced significant waste, these new facilities are designed with environmental performance baked into their DNA. For example, the Rouge Electric Vehicle Center was retrofitted to produce the F-150 Lightning while reducing energy consumption by 30% compared to older models’ production. This wasn’t achieved through minor tweaks—it required a complete reimagining of operations, from lighting and HVAC systems to water usage and material sourcing.

Zero-Waste-to-Landfill and Energy Efficiency

One of the most impressive achievements of the Ford Electric Car Plant is its commitment to zero-waste-to-landfill status across all North American facilities. Since 2010, Ford has diverted over 2.5 billion pounds of waste from landfills, and its electric vehicle plants go even further. At the Rouge Center, for instance, over 99% of waste materials—including metal shavings, plastic packaging, and paint sludge—are recycled, reused, or repurposed. Paint overspray is captured and turned into construction materials, while scrap aluminum is sent back to suppliers for re-melting.

Energy efficiency is another cornerstone. The plants use high-efficiency LED lighting, variable-speed drives on machinery, and advanced thermal insulation to minimize power consumption. Solar panels installed on rooftops and parking canopies contribute renewable energy, with plans to expand on-site generation. The Tennessee plant, BlueOval City, aims to operate on 100% carbon-free electricity by 2025, leveraging wind, solar, and grid decarbonization efforts.

- Tip: When evaluating sustainable manufacturing, look for third-party certifications like ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design). Ford’s electric plants hold multiple such accreditations.

- Example: The Kentucky Truck Plant, which produces the Super Duty F-Series, now supports battery-electric variants and uses a closed-loop water system that recycles 95% of process water.

BlueOval City: The Future of EV Manufacturing

A $5.6 Billion Investment in the South

Perhaps the most ambitious project in Ford’s electrification journey is BlueOval City, a massive 3,600-acre campus in Stanton, Tennessee. Announced in 2021 and opening in phases starting in 2025, this $5.6 billion complex will serve as the epicenter of Ford’s next-generation electric vehicles, including the all-new electric F-Series pickup and a family of electric SUVs. BlueOval City isn’t just a factory—it’s a vertically integrated ecosystem combining vehicle assembly, battery production, supplier parks, and employee training centers.

What sets BlueOval City apart is its scale and integration. Unlike traditional “hub-and-spoke” models where components are shipped in from distant suppliers, Ford is co-locating key partners like SK On (battery cells) and Magna International (interiors) within the campus. This reduces transportation emissions, cuts logistics costs, and improves supply chain resilience—critical factors in a world grappling with global disruptions.

Integrated Battery Production and Circular Economy

At the heart of BlueOval City is the BlueOval SK Battery Park, a joint venture between Ford and SK On that will produce 43 gigawatt-hours (GWh) of battery cells annually—enough to power over 400,000 EVs per year. These batteries use a nickel-manganese-cobalt (NMC) chemistry optimized for energy density, longevity, and recyclability. But Ford doesn’t stop at production; it’s pioneering closed-loop recycling through a partnership with Redwood Materials, founded by former Tesla CTO JB Straubel.

Redwood will process end-of-life batteries and manufacturing scrap from BlueOval City to recover lithium, cobalt, nickel, and copper. These recovered materials will then be refined and fed back into new battery production, reducing reliance on mining and cutting lifecycle emissions by up to 70%. This circular model is a game-changer—it turns waste into a resource and creates a self-sustaining supply chain.

- Tip: Consumers can support circular economy efforts by choosing brands that offer battery take-back programs or use recycled materials in their EVs.

- Example: The F-150 Lightning’s battery pack contains 25% recycled content, and Ford plans to increase this to 50% by 2030.

Smart Manufacturing and Digital Twins

BlueOval City leverages Industry 4.0 technologies to optimize efficiency and quality. The facility uses digital twin technology—a virtual replica of the entire plant—to simulate operations, predict maintenance needs, and test process changes before implementation. Sensors embedded in machinery provide real-time data on performance, energy use, and emissions, enabling predictive analytics and rapid problem-solving.

Robotics and AI play a crucial role too. Collaborative robots (cobots) assist workers with repetitive tasks like lifting heavy battery modules, reducing injury risk and increasing precision. AI-powered vision systems inspect every vehicle for defects, ensuring consistent quality. These innovations don’t just make production faster—they make it smarter and more sustainable.

Workforce Transformation and Community Impact

Upskilling the American Workforce

Transitioning from internal combustion engines (ICE) to electric vehicles requires more than new machinery—it demands a new kind of workforce. Ford has committed to training over 100,000 employees in EV-related skills by 2030, with a focus on battery technology, software engineering, and data science. The Ford Electric Car Plant network serves as a living classroom, offering apprenticeships, certification programs, and partnerships with local community colleges.

The Ford Next Generation Learning (NGL) initiative, for example, partners with schools in Tennessee and Michigan to develop EV-focused curricula. Students learn about battery chemistry, charging infrastructure, and sustainable design, preparing them for careers in the green economy. This investment in human capital ensures that Ford’s sustainability efforts are powered by skilled, motivated workers.

Community Engagement and Economic Revitalization

Beyond jobs, Ford’s electric plants are revitalizing communities. BlueOval City alone will create 6,000 direct jobs and support tens of thousands of indirect positions in construction, logistics, and services. Local governments have invested in infrastructure upgrades—new roads, expanded broadband, and workforce housing—to accommodate growth.

Ford also prioritizes community engagement through programs like the Ford Fund, which provides grants for education, workforce development, and environmental initiatives. In Tennessee, the company has funded solar panel installations in schools and supported reforestation projects to offset construction impacts. These efforts build goodwill and ensure that the benefits of electrification are shared equitably.

- Tip: If you’re part of a community considering an EV plant, advocate for inclusive hiring policies, affordable housing, and green infrastructure.

- Example: The Rouge Electric Vehicle Center includes a community solar garden that powers 1,000 homes and serves as a model for urban sustainability.

Addressing the “Just Transition” Challenge

The shift to EVs raises concerns about job displacement in traditional auto sectors. Ford is tackling this head-on with its “just transition” strategy, offering retraining programs and early retirement packages to workers in declining ICE operations. The company has also committed to maintaining union partnerships, ensuring that EV jobs offer the same wages, benefits, and protections as legacy roles.

Supply Chain Sustainability and Ethical Sourcing

Responsible Sourcing of Critical Minerals

Electric vehicles rely on rare earth elements, lithium, cobalt, and nickel—minerals often associated with environmental degradation and human rights abuses. Ford is taking a proactive stance through its Responsible Sourcing Program, which requires suppliers to adhere to strict environmental, social, and governance (ESG) standards. The company conducts third-party audits, maps its supply chain down to the mine level, and uses blockchain technology to verify ethical practices.

For cobalt, Ford has partnered with the Responsible Minerals Initiative (RMI) and supports artisanal mining cooperatives in the Democratic Republic of Congo with fair wages and safety training. For lithium, it’s investing in direct extraction from geothermal brines in California, a process that uses 80% less water than traditional mining.

Localizing the Supply Chain

Global supply chain disruptions during the pandemic highlighted the risks of over-reliance on overseas suppliers. Ford is now localizing key components, with 70% of battery materials and 50% of motors sourced from North America by 2026. BlueOval City will house a dedicated supplier park, reducing transport emissions and improving responsiveness.

Ford has also signed long-term agreements with U.S.-based mining companies like Compass Minerals and Albemarle to secure lithium and nickel. These deals include provisions for renewable energy use in extraction and processing, further reducing the carbon footprint of raw materials.

- Tip: Look for EVs with transparent supply chain disclosures. Ford publishes annual sustainability reports detailing sourcing practices and progress toward ESG goals.

- Example: The Mustang Mach-E uses cobalt-free lithium iron phosphate (LFP) batteries in some trims, eliminating a controversial mineral entirely.

Reducing Logistics Emissions

Transportation accounts for a significant portion of manufacturing emissions. Ford’s electric plants are designed with rail spurs, electric delivery trucks, and charging stations for freight vehicles. The company is also piloting hydrogen-powered trucks for regional hauling, aiming to cut logistics emissions by 50% by 2030.

Consumer Benefits and the Road Ahead

Lower Total Cost of Ownership

While EVs often have higher upfront costs, the Ford Electric Car Plant is helping to close the price gap. Economies of scale, vertical integration, and efficient manufacturing are driving down production costs. The F-150 Lightning, for instance, starts at $49,995—competitive with many ICE trucks—and benefits from lower maintenance, fuel, and tax incentives.

Ford estimates that EV owners save $1,000–$2,000 annually on fuel and maintenance. The company also offers a 8-year/100,000-mile battery warranty, providing long-term peace of mind.

Enhanced Performance and Features

Electric vehicles from Ford’s new plants offer superior performance. The F-150 Lightning delivers 563 horsepower and 775 lb-ft of torque, enabling 0–60 mph in 4.5 seconds. The Mustang Mach-E boasts a range of up to 314 miles, while the E-Transit van supports fleet operators with 126 miles per charge.

Smart features like Ford Power-Up over-the-air updates, BlueCruise hands-free driving, and Pro Power Onboard (which turns the truck into a mobile generator) enhance utility and convenience.

Charging Infrastructure and Grid Integration

Ford is expanding its BlueOval Charge Network, which includes over 100,000 public chargers across North America. The company also offers home charging solutions with 24/7 support. Looking ahead, Ford is exploring vehicle-to-grid (V2G) technology, allowing EVs to feed energy back into the grid during peak demand—turning cars into distributed power sources.

Future Roadmap: 2025 and Beyond

By 2025, Ford aims to produce 2 million EVs annually, with 100% of its European lineup electrified. The company is developing a new “skateboard” EV platform for affordable models and investing in solid-state battery research. BlueOval City will eventually support autonomous vehicle production, further integrating sustainability with cutting-edge tech.

Data Table: Ford Electric Car Plant Sustainability Metrics (2023)

| Metric | Rouge EV Center (MI) | BlueOval City (TN) | Kentucky Plant (KY) |

|---|---|---|---|

| Annual EV Production Capacity | 150,000 units | 400,000 units (by 2026) | 100,000 units |

| Renewable Energy Use | 60% (solar + grid) | 100% (by 2025) | 40% (wind + solar) |

| Water Recycled | 85% | 90% (closed-loop system) | 95% |

| Waste to Landfill | 0.5% | 0% (goal) | 1% |

| CO2 Emissions per Vehicle | 1.8 tons (vs. 3.2 tons ICE) | 1.2 tons (projected) | 2.0 tons |

| Local Hiring Rate | 75% | 80% | 70% |

| Battery Recycling Partner | Redwood Materials | Redwood + SK On | Redwood Materials |

The Ford Electric Car Plant represents more than a technological leap—it’s a holistic rethinking of what sustainable manufacturing can achieve. By integrating clean energy, circular economy principles, ethical sourcing, and workforce development, Ford is proving that environmental responsibility and industrial growth can go hand in hand. These plants are not just producing electric vehicles; they’re shaping a cleaner, fairer, and more resilient future for transportation.

As consumers, we have a role to play. By choosing EVs built in sustainable facilities like Ford’s, supporting green policies, and advocating for equitable transitions, we can accelerate the shift toward a net-zero future. The road ahead is electric, and thanks to innovations like the Ford Electric Car Plant, it’s also sustainable. The revolution is here—and it’s just getting started.

Frequently Asked Questions

What is the Ford electric car plant and where is it located?

The Ford electric car plant refers to Ford’s state-of-the-art manufacturing facilities dedicated to producing electric vehicles (EVs), including the flagship Ford Rouge Electric Vehicle Center in Michigan. This plant is a cornerstone of Ford’s $50 billion investment in electrification and sustainable production.

How does the Ford electric car plant support sustainability?

The plant integrates eco-friendly practices like renewable energy use, zero waste-to-landfill operations, and energy-efficient manufacturing processes. By minimizing carbon emissions and water usage, it aligns with Ford’s goal of carbon neutrality by 2050.

Which electric vehicles are produced at the Ford electric car plant?

The plant currently produces popular models like the Ford F-150 Lightning and the Mustang Mach-E, with plans to expand its lineup. These EVs are designed to combine performance, utility, and zero-emission driving.

How many jobs has the Ford electric car plant created?

The plant has generated thousands of jobs, both directly in manufacturing and indirectly in supply chains and infrastructure development. This supports Ford’s commitment to revitalizing American automotive employment through EV innovation.

What makes the Ford electric car plant different from traditional auto factories?

Unlike traditional plants, it features advanced automation, battery production lines, and a focus on circular economy principles, such as recycling scrap materials. This ensures higher efficiency and lower environmental impact.

Is Ford expanding its electric car plant network globally?

Yes, Ford is expanding its EV manufacturing footprint with new facilities in Tennessee (BlueOval City) and Germany, in addition to upgrading existing plants. These expansions aim to meet rising global demand for electric vehicles.