Ford Electric Car Plants Powering the Future of EVs

Featured image for ford electric car plants

Image source: tellmebest.com

Ford is revolutionizing the EV landscape with its massive investment in electric car plants, including the groundbreaking BlueOval City and Rouge Electric Vehicle Center. These state-of-the-art facilities are set to supercharge production of the F-150 Lightning and future EV models, cementing Ford’s position as an American leader in the electric revolution. With advanced manufacturing, sustainable practices, and a $50 billion commitment, Ford’s electric car plants are powering the future of transportation.

Key Takeaways

- Ford is investing $50B+ in EV plants to dominate the electric vehicle market by 2026.

- BlueOval City leads innovation with advanced manufacturing for next-gen EVs and batteries.

- Vertical integration cuts costs by producing batteries in-house at scale across U.S. plants.

- Job creation is accelerating with 11,000+ new roles tied to EV plant expansions.

- Sustainability drives design using 100% renewable energy at key EV production facilities.

📑 Table of Contents

- Ford Electric Car Plants Powering the Future of EVs

- The Strategic Vision Behind Ford’s EV Manufacturing

- Key Ford Electric Car Plants: Locations and Capabilities

- Technology and Sustainability: How Ford’s EV Plants Are Built to Last

- Economic and Community Impact of Ford’s EV Plants

- Challenges and Future Outlook

- Data Snapshot: Ford’s EV Plants at a Glance

- Conclusion: A New Era of American Manufacturing

Ford Electric Car Plants Powering the Future of EVs

In the rapidly evolving world of electric vehicles (EVs), few names carry the weight and legacy of Ford Motor Company. With over a century of automotive innovation, Ford is now pivoting decisively toward a sustainable future, and its electric car plants are at the heart of this transformation. As global demand for cleaner transportation surges, Ford is investing billions to retool existing factories and build new state-of-the-art facilities dedicated to EVs. These plants aren’t just manufacturing hubs—they’re the foundation of Ford’s bold strategy to lead the EV revolution.

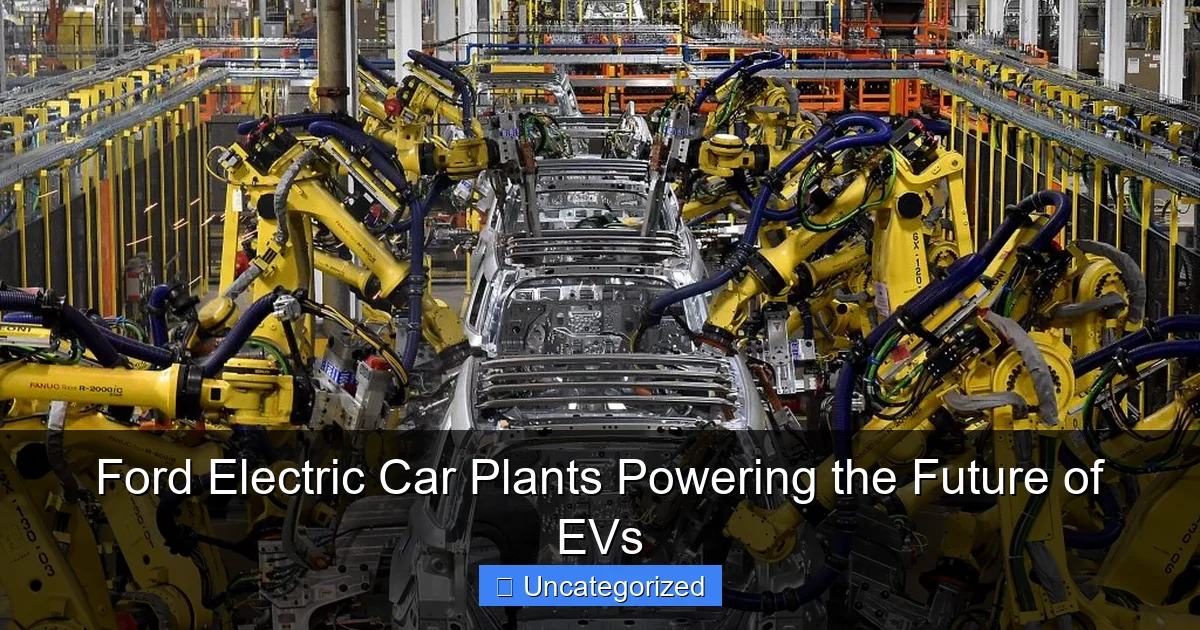

The shift to electric vehicles represents one of the most significant industrial transitions in modern history. Ford’s electric car plants are more than just production lines; they’re symbols of a new era in mobility, combining advanced automation, renewable energy integration, and workforce retraining. From the historic Rouge Complex in Dearborn to the newly christened BlueOval City in Tennessee, Ford is reimagining what an automotive factory can be. This blog post dives deep into Ford’s electric car plants, exploring their locations, technologies, economic impact, and the pivotal role they play in shaping the future of transportation.

The Strategic Vision Behind Ford’s EV Manufacturing

From Legacy to Innovation: Ford’s EV Pivot

Ford’s journey into the electric era began in earnest with the launch of the Mustang Mach-E in 2020, followed by the F-150 Lightning in 2021—a bold move to electrify America’s best-selling vehicle. Unlike some competitors who built EVs from scratch, Ford’s strategy leverages its existing manufacturing footprint, transforming traditional plants into EV powerhouses. This “repurpose and reinvent” approach allows Ford to maintain production efficiency while minimizing capital waste.

Visual guide about ford electric car plants

Image source: goodnewsnetwork.org

The cornerstone of this vision is the Ford+ Plan, a $50 billion investment strategy announced in 2021, with $30 billion specifically earmarked for EVs through 2025. A key component of this plan is the BlueOval SK joint venture with SK On, a South Korean battery manufacturer, which aims to secure a stable, high-quality supply of lithium-ion battery cells. This vertical integration is critical to Ford’s ability to scale EV production and control costs.

Global Manufacturing Strategy: U.S. Focus with Global Ambitions

While Ford operates globally, its EV manufacturing strategy is heavily concentrated in the United States—a deliberate choice driven by federal incentives, supply chain proximity, and domestic demand. The U.S. Inflation Reduction Act (IRA) of 2022, which offers tax credits for EVs assembled in North America with batteries sourced from free-trade partners, has further incentivized Ford to build and expand its domestic EV plants.

Ford’s U.S.-centric approach includes:

- Retooling legacy plants in Michigan, Illinois, and Missouri to produce EVs.

- Building new gigafactories like BlueOval City and BlueOval SK Battery Park in Kentucky and Tennessee.

- Partnering with local communities to ensure workforce development and infrastructure readiness.

This strategy not only strengthens Ford’s supply chain resilience but also aligns with growing consumer and policy support for American-made EVs.

Key Ford Electric Car Plants: Locations and Capabilities

BlueOval City: The Crown Jewel of Ford’s EV Future

Located in Stanton, Tennessee, BlueOval City is Ford’s most ambitious EV plant to date. Spanning 3,600 acres—roughly the size of 2,700 football fields—this $5.6 billion facility is designed to produce 500,000 EVs annually starting in 2025. It will be the exclusive home of Ford’s next-generation electric pickup, currently codenamed Project T3 (Trust, Transform, Thrive).

Key features of BlueOval City include:

- Integrated battery plant: A 4 million sq. ft. BlueOval SK battery facility on-site will produce 43 GWh of lithium-ion batteries annually—enough for 500,000 vehicles.

- Carbon-neutral operations: Ford aims for the plant to run on 100% renewable energy, using solar, wind, and biogas.

- Smart factory technology: AI-driven robotics, real-time data analytics, and digital twins will optimize production and reduce downtime.

The plant will create 6,000 new jobs and serve as a model for sustainable, high-volume EV manufacturing.

BlueOval SK Battery Park: Powering the EV Revolution

Adjacent to BlueOval City, Ford and SK On are building BlueOval SK Battery Park in Glendale, Kentucky. This $5.8 billion joint venture will house two battery manufacturing plants, each capable of producing 43 GWh of battery capacity annually—totaling 86 GWh, enough for over 1 million EVs per year. The first plant began production in late 2023, with the second scheduled for 2024.

This facility is critical for Ford’s battery supply chain. By co-locating with BlueOval City, Ford reduces transportation costs and battery degradation risks. The Kentucky site will also support the F-150 Lightning and future Ford and Lincoln EVs, ensuring a steady flow of batteries as demand grows.

Dearborn Rouge Electric Vehicle Center: Revitalizing a Legend

The Rouge Complex in Dearborn, Michigan, is one of Ford’s most historic sites—home to the original Model T and the birthplace of the modern assembly line. In 2021, Ford transformed part of this facility into the Dearborn Rouge Electric Vehicle Center, dedicated to producing the F-150 Lightning.

This $700 million retooling project showcases Ford’s ability to modernize legacy infrastructure. The plant uses:

- Modular production lines that can switch between ICE and EV models.

- Automated guided vehicles (AGVs) to move components with precision.

- Energy-efficient lighting and HVAC systems to reduce the plant’s carbon footprint.

With a capacity of 150,000 F-150 Lightning units annually, the Rouge Center proves that heritage and innovation can coexist.

Other Key Facilities: Chicago, Oakville, and Beyond

Beyond its flagship EV plants, Ford is expanding EV production across North America:

- Chicago Assembly Plant: Now produces the Ford Explorer and Lincoln Aviator plug-in hybrids, with plans to add full EV models.

- Oakville Assembly Complex (Canada): Undergoing a $1.8 billion retooling to produce next-generation EVs starting in 2025.

- Kansas City Assembly Plant: Produces the E-Transit electric van, with capacity for 38,000 units annually.

These facilities ensure Ford can meet diverse market needs—from commercial vans to luxury SUVs—while maintaining a flexible, scalable manufacturing network.

Technology and Sustainability: How Ford’s EV Plants Are Built to Last

Smart Manufacturing and Digital Twins

Ford’s EV plants are at the forefront of Industry 4.0. At BlueOval City, engineers use digital twin technology to create a virtual replica of the entire facility. This allows them to simulate production flows, identify bottlenecks, and optimize layouts before construction even begins. The digital twin is updated in real time, enabling predictive maintenance and rapid troubleshooting.

Other tech innovations include:

- AI-powered quality control: Cameras and machine learning algorithms inspect welds, paint finishes, and battery integrity with 99.8% accuracy.

- 5G connectivity: High-speed networks enable real-time communication between robots, vehicles, and control systems.

- Robotic process automation (RPA): Robots handle repetitive tasks like battery installation and panel fitting, improving precision and worker safety.

These technologies reduce production time by up to 30% and cut defect rates by half compared to traditional plants.

Renewable Energy and Carbon Reduction Goals

Ford has committed to achieving carbon neutrality across its global operations by 2035. Its EV plants are central to this mission. For example:

- BlueOval City will use 100% renewable energy, with on-site solar arrays and partnerships with local wind farms.

- BlueOval SK Battery Park is powered by a 150 MW solar farm developed by a third-party provider.

- Dearborn Rouge Center uses a 10 MW solar canopy and a biogas system that converts waste into energy.

Ford also recycles 90% of its manufacturing waste and is piloting closed-loop water systems that reduce consumption by 40%.

Workforce Training and the Future of Auto Jobs

EV manufacturing requires a new skill set. Ford is investing heavily in workforce development through programs like:

- Ford University: Offers online and in-person training in EV systems, battery safety, and advanced robotics.

- Apprenticeship programs with community colleges in Tennessee and Kentucky, focusing on high-voltage systems and automation.

- Reskilling initiatives for existing ICE plant workers, ensuring no one is left behind in the transition.

These efforts not only prepare workers for the EV era but also strengthen community ties and reduce labor turnover.

Economic and Community Impact of Ford’s EV Plants

Job Creation and Local Investment

Ford’s EV plants are economic catalysts. BlueOval City alone will create 6,000 direct jobs and 10,000 indirect jobs in construction, logistics, and services. The project has spurred $1.2 billion in private investment across West Tennessee, including new housing, schools, and infrastructure.

In Kentucky, the BlueOval SK Battery Park has attracted suppliers like LG Energy Solution and Panasonic to open nearby facilities. This clustering effect creates a battery ecosystem that reduces shipping costs and boosts regional competitiveness.

Supporting Small Businesses and Local Economies

Ford prioritizes local sourcing. For example:

- Over 70% of construction materials for BlueOval City come from within 500 miles.

- The company partners with minority- and women-owned businesses for 30% of its contracts.

- It funds small business incubators in nearby towns to help entrepreneurs enter the EV supply chain.

These initiatives ensure that the economic benefits of EV manufacturing are widely shared.

Workforce Diversity and Inclusion

Ford is committed to building a diverse EV workforce. At BlueOval City, 40% of new hires are women or people of color—above the industry average. The company also partners with historically Black colleges and universities (HBCUs) to recruit engineering talent.

Challenges and Future Outlook

Supply Chain and Raw Material Constraints

Despite its progress, Ford faces challenges. The EV industry is heavily reliant on critical minerals like lithium, cobalt, and nickel—resources concentrated in politically unstable regions. To mitigate risk, Ford is:

- Securing long-term contracts with mining companies in Australia, Canada, and the U.S.

- Investing in battery recycling through partnerships with Redwood Materials to recover 95% of battery materials.

- Exploring alternative chemistries like lithium iron phosphate (LFP) batteries, which use fewer rare materials.

These strategies aim to reduce dependency on volatile global markets.

Scaling Production to Meet Demand

Ford has over 200,000 reservations for the F-150 Lightning and faces long waitlists for the Mustang Mach-E. To scale, the company is:

- Accelerating factory ramp-ups using modular production techniques.

- Expanding battery supply with additional BlueOval SK plants in the U.S. and Europe.

- Partnering with third-party assemblers for niche models, like the E-Transit chassis cab.

By 2026, Ford aims to produce 2 million EVs annually—a 10x increase from 2022.

The Road Ahead: 2025 and Beyond

Looking forward, Ford plans to:

- Launch a new affordable EV platform in 2025, targeting $25,000–$30,000 price points.

- Expand into commercial EVs, including electric delivery vans and medium-duty trucks.

- Explore solid-state battery technology through partnerships with QuantumScape and others.

These initiatives will position Ford as a leader in both consumer and fleet electrification.

Data Snapshot: Ford’s EV Plants at a Glance

| Plant | Location | Investment | Capacity (Annual) | Key Vehicles | Start of Production |

|---|---|---|---|---|---|

| BlueOval City | Stanton, TN | $5.6 billion | 500,000 EVs | Project T3 Pickup | 2025 |

| BlueOval SK Battery Park | Glendale, KY | $5.8 billion (joint) | 86 GWh batteries | Batteries for F-150, Mach-E, etc. | 2023 (Phase 1) |

| Dearborn Rouge EV Center | Dearborn, MI | $700 million | 150,000 units | F-150 Lightning | 2021 |

| Kansas City Assembly | Kansas City, MO | $100 million | 38,000 units | E-Transit Van | 2021 |

| Oakville Assembly Complex | Oakville, ON | $1.8 billion | 250,000 units (planned) | Next-gen EVs | 2025 |

Conclusion: A New Era of American Manufacturing

Ford’s electric car plants are more than factories—they’re engines of transformation. By combining cutting-edge technology, sustainable practices, and community engagement, Ford is redefining what it means to build vehicles in the 21st century. These facilities are not just producing EVs; they’re shaping the future of mobility, creating jobs, and reducing carbon emissions on a massive scale.

As the world accelerates toward electrification, Ford’s strategic investments in manufacturing infrastructure give it a competitive edge. From the solar-powered gigafactories of Tennessee to the retooled assembly lines of Michigan, Ford is proving that legacy automakers can lead the EV revolution. The road ahead is challenging, but with its network of electric car plants, Ford is powering a cleaner, smarter, and more sustainable future for all.

Frequently Asked Questions

Where are Ford’s electric car plants located?

Ford’s key EV manufacturing plants are in the U.S., including the Rouge Electric Vehicle Center (Michigan), BlueOval City (Tennessee), and BlueOval SK Battery Park (Kentucky). These facilities form the backbone of Ford’s $50 billion electrification strategy.

How many electric vehicles can Ford’s plants produce annually?

By 2026, Ford’s EV plants aim to reach a combined production capacity of over 2 million electric vehicles per year globally. The Tennessee and Kentucky plants alone will support 129 gigawatt-hours of battery production annually.

What Ford EVs are made at these electric car plants?

The Rouge EV Center produces the F-150 Lightning, while BlueOval City will manufacture next-gen electric trucks and advanced batteries. The Kentucky SK plant focuses on battery modules for Ford’s expanding EV lineup.

How is Ford making its EV plants more sustainable?

Ford’s electric car plants use 100% renewable energy, closed-loop water systems, and zero-waste-to-landfill practices. BlueOval City features solar canopies and a 3.5-mile stormwater recycling system to minimize environmental impact.

Why did Ford choose Tennessee and Kentucky for its EV plants?

These locations offer strategic access to transportation hubs, skilled labor, and renewable energy sources. The “megasite” in Tennessee provides 4,000+ acres for integrated EV and battery production.

How do Ford’s EV plants compare to traditional auto factories?

Ford’s EV plants feature modular assembly lines and AI-driven quality control systems designed specifically for electric vehicles. They’re 25% more energy-efficient than conventional plants while supporting higher production volumes.