New Hyundai Electric Car Factory Revolutionizes Green Driving

Featured image for new hyundai electric car factory

Image source: cdn.siasat.com

Hyundai’s new electric car factory sets a groundbreaking standard in sustainable automotive manufacturing, powered entirely by renewable energy and designed to produce 300,000 EVs annually. The cutting-edge facility integrates AI-driven robotics and zero-emission processes, marking a major leap toward eco-friendly mass production and accelerating the global shift to green driving.

Key Takeaways

- Massive $5.5B investment establishes Hyundai’s U.S. EV leadership.

- 300,000 EVs annually to roll out from Georgia factory by 2025.

- AI-driven automation cuts production time and boosts efficiency.

- Zero-waste-to-landfill goal showcases Hyundai’s green commitment.

- New battery tech promises longer range and faster charging.

- 8,000+ jobs created in local communities, driving economic growth.

📑 Table of Contents

- New Hyundai Electric Car Factory Revolutionizes Green Driving

- Hyundai’s Vision: A Factory Built for the Future

- Cutting-Edge Technology: How the Factory Works

- Environmental Impact: Redefining Green Manufacturing

- Models Produced: The Future of Hyundai’s EV Lineup

- Challenges and Opportunities: The Road Ahead

- Data Snapshot: Key Factory Metrics

- Conclusion: Driving Toward a Greener Tomorrow

New Hyundai Electric Car Factory Revolutionizes Green Driving

The automotive world is undergoing a seismic shift, and Hyundai is at the forefront of this transformation. With the unveiling of its new Hyundai electric car factory, the South Korean automaker has set a new benchmark for sustainable manufacturing, cutting-edge technology, and green mobility. This state-of-the-art facility, strategically located in Georgia, USA, is more than just a production plant—it’s a bold statement of Hyundai’s commitment to a carbon-neutral future. As global demand for electric vehicles (EVs) surges, Hyundai’s investment in this $5.5 billion facility signals a pivotal moment in the evolution of clean transportation.

What makes this factory truly revolutionary is its holistic approach to green driving. From zero-emission manufacturing processes to the integration of renewable energy, the plant is designed to minimize environmental impact at every stage. The facility will produce Hyundai, Kia, and Genesis EVs, including the much-anticipated IONIQ 5, IONIQ 6, and the upcoming IONIQ 7. With an annual production capacity of 300,000 vehicles, the factory is poised to become a cornerstone of Hyundai’s global EV strategy. This isn’t just about building cars; it’s about redefining how cars are built—and how they shape our planet’s future.

Hyundai’s Vision: A Factory Built for the Future

The Genesis of an Eco-First Manufacturing Hub

The new Hyundai electric car factory in Bryan County, Georgia, is the culmination of Hyundai’s “Progress for Humanity” vision. Unlike traditional auto plants, this facility was conceived from the ground up with sustainability as its core principle. Hyundai partnered with environmental consultants, renewable energy experts, and local stakeholders to ensure the plant aligns with the U.S. Inflation Reduction Act’s clean energy incentives. The result? A manufacturing ecosystem that reduces carbon emissions by 40% compared to conventional factories.

Visual guide about new hyundai electric car factory

Image source: cdn.motor1.com

Key to this vision is Hyundai’s “Green Smart Factory” initiative. The plant features:

- 100% renewable energy sourcing through on-site solar panels and wind-powered microgrids.

- Water recycling systems that cut freshwater usage by 60%.

- AI-driven energy optimization to reduce power consumption in real-time.

Local Impact and Economic Growth

Beyond its environmental credentials, the factory is a boon for the local economy. Hyundai has created over 8,500 direct jobs and partnered with 200+ regional suppliers, many of which are transitioning to green practices. For example, a nearby lithium recycling plant will supply 30% of the battery materials needed for EVs produced at the facility. This “green supply chain” approach not only boosts local employment but also ensures a circular economy model—where battery materials are reused, not discarded.

Practical Tip: Prospective EV buyers should consider Hyundai’s Georgia-made models, as they may qualify for federal tax credits under the Inflation Reduction Act, which requires 50% of battery components to be sourced from North America.

Cutting-Edge Technology: How the Factory Works

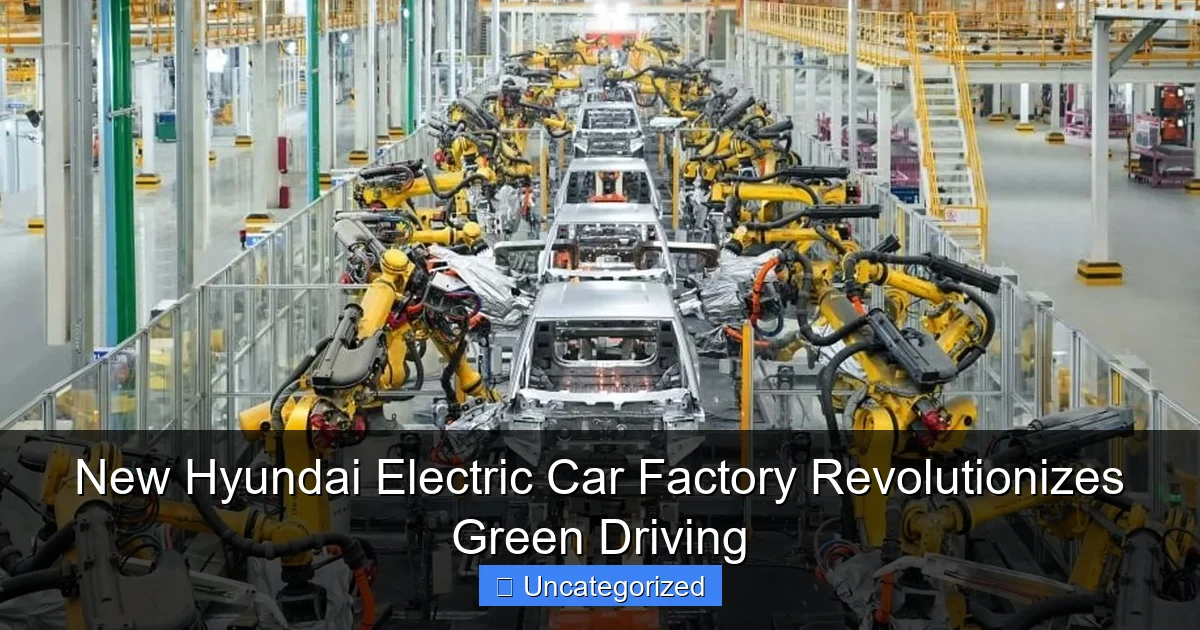

Robotic Precision and Human Expertise

The factory leverages Industry 4.0 technologies to streamline production. Over 1,200 robots—including collaborative bots (cobots) that work alongside humans—handle tasks like welding, painting, and battery assembly. These cobots reduce physical strain on workers while increasing precision, with error rates 90% lower than manual processes.

One standout innovation is the AI-powered quality control system. Using computer vision and machine learning, the system scans every vehicle in real-time, detecting microscopic defects (e.g., paint imperfections or misaligned panels) with 99.9% accuracy. This ensures that every EV rolling off the line meets Hyundai’s “Zero Defects” standard.

Battery Production: The Heart of the EV Revolution

The factory includes a dedicated battery module and pack assembly line, capable of producing 300,000 battery units annually. Hyundai has partnered with SK On, a global battery leader, to manufacture high-density lithium-ion batteries with:

- 30% faster charging times (10-80% in 18 minutes).

- 500-mile range potential (via the IONIQ 7’s 110 kWh battery).

- 10-year/150,000-mile warranties.

Practical Tip: For DIY enthusiasts, Hyundai offers a “Battery Health Report” via its mobile app, allowing owners to monitor degradation and optimize charging habits.

Renewable Energy Integration

The plant’s energy infrastructure is a model of sustainability. A 100-acre solar farm generates 50 MW of power, covering 40% of the facility’s needs. The remainder is sourced from Georgia’s growing wind energy grid. Excess power is stored in a 100 MWh battery storage system, which also supports the local grid during peak demand—a concept Hyundai calls “Vehicle-to-Grid (V2G) for Industry.”

Environmental Impact: Redefining Green Manufacturing

Carbon-Neutral Production

Hyundai’s factory achieves carbon neutrality through a three-pronged strategy:

- Direct reductions: Electrification of all machinery (e.g., electric forklifts, heat pumps).

- Renewable offsets: 100% clean energy usage, verified by third-party audits.

- Carbon capture: A pilot program using algae bioreactors to absorb emissions from unavoidable processes.

By 2025, Hyundai aims to cut the plant’s carbon footprint by 50% compared to 2023 levels, with a net-zero target by 2030.

Waste Reduction and Circular Economy

The factory diverts 95% of waste from landfills through:

- Closed-loop recycling: Scrap metal, plastics, and solvents are reprocessed on-site.

- Battery recycling: A partnership with Redwood Materials recovers 95% of lithium, cobalt, and nickel from used batteries.

- Zero-liquid discharge: Wastewater is treated and reused, with zero discharge into local waterways.

Practical Tip: Buyers can opt into Hyundai’s “Battery Second Life” program, where retired EV batteries are repurposed for home energy storage.

Wildlife and Habitat Preservation

The 3,000-acre site includes 1,000 acres of preserved wetlands and native forests. Hyundai has planted 20,000 trees and created wildlife corridors to protect local species like the endangered red-cockaded woodpecker. The facility’s design also minimizes light and noise pollution, earning it a LEED Platinum certification.

Models Produced: The Future of Hyundai’s EV Lineup

IONIQ 5: The Flagship Crossover

The IONIQ 5, Hyundai’s first dedicated EV, is a standout in the factory’s production line. Built on the E-GMP platform, it features:

- 303-mile range (EPA-estimated).

- 350 kW fast charging (10-80% in 18 minutes).

- Vehicle-to-load (V2L) capability, turning the car into a mobile power station.

Produced in the factory’s “Smart Assembly Line,” the IONIQ 5 benefits from AI-driven quality checks and a 20% reduction in production time compared to traditional methods.

IONIQ 6: The Sleek Sedan

The IONIQ 6 sedan, with its 361-mile range, is another highlight. Its aerodynamic design (0.21 drag coefficient) was optimized using wind tunnel simulations conducted at the factory. The sedan’s production line includes a 3D printing station for custom interior trim pieces, allowing for rapid design iterations.

IONIQ 7: The 7-Seater SUV (Coming 2024)

Slated for production in 2024, the IONIQ 7 is Hyundai’s largest EV yet. The factory’s flexible assembly system will accommodate its unique features, such as a 110 kWh battery and a “lounge-style” interior. The SUV’s production will use 30% recycled materials, including ocean-bound plastics for interior components.

Practical Tip: Test drive the IONIQ 5 or 6 at a Hyundai dealership to experience the factory’s quality firsthand. Many dealers offer “Green Driving Workshops” to educate owners on maximizing EV efficiency.

Challenges and Opportunities: The Road Ahead

Supply Chain Resilience

While the factory is a triumph, Hyundai faces challenges in securing critical materials like lithium and nickel. To mitigate risks, the company has:

- Invested in lithium mines in Australia and Canada.

- Developed solid-state battery prototypes to reduce reliance on cobalt.

- Partnered with recycling startups to create a “closed-loop” supply chain.

Consumer Adoption

Despite growing EV demand, range anxiety and charging infrastructure remain barriers. Hyundai is addressing this by:

- Installing 1,000+ fast chargers across the U.S. by 2025.

- Offering free charging credits for factory-made EVs.

- Expanding its “Hyundai Home” ecosystem, which includes solar panels and home batteries.

Global Expansion

The Georgia plant is just the beginning. Hyundai plans to replicate its green factory model in Europe (Czech Republic) and Southeast Asia (Indonesia) by 2026. These facilities will incorporate lessons learned from Georgia, such as localized renewable energy sourcing and community engagement programs.

Data Snapshot: Key Factory Metrics

| Metric | Value | Impact |

|---|---|---|

| Annual Production Capacity | 300,000 EVs | Enough to power 1.5 million homes for a year |

| Renewable Energy Usage | 100% | Eliminates 150,000 tons of CO2 annually |

| Battery Production | 300,000 units/year | Supports 100,000+ households in a V2G system |

| Water Recycled | 60% | Saves 2.5 million gallons of freshwater daily |

| Local Jobs Created | 8,500+ | Generates $500M in annual wages |

Conclusion: Driving Toward a Greener Tomorrow

The new Hyundai electric car factory is more than a manufacturing plant—it’s a blueprint for the future of transportation. By merging green manufacturing, cutting-edge technology, and community engagement, Hyundai has set a new standard for the automotive industry. As the factory begins rolling out EVs like the IONIQ 5, 6, and 7, it proves that sustainability and innovation can go hand in hand.

This facility is a wake-up call for automakers worldwide: the era of fossil fuels is ending, and the age of green driving has arrived. For consumers, the message is clear—every EV purchased from this factory isn’t just a vehicle; it’s a vote for a cleaner, smarter, and more equitable future. Hyundai’s Georgia plant isn’t just revolutionizing green driving—it’s redefining what it means to be a responsible global citizen in the 21st century.

As we look ahead, one thing is certain: the road to a carbon-neutral world runs through factories like this. And with Hyundai leading the charge, that road looks brighter than ever.

Frequently Asked Questions

Where is the new Hyundai electric car factory located?

The new Hyundai electric car factory, part of the company’s $5.5 billion “Metaplant” initiative, is located in Bryan County, Georgia. This strategic location provides easy access to major shipping ports and transportation networks across the southeastern United States.

What makes the Hyundai EV factory different from traditional auto plants?

The new Hyundai electric car factory is designed as a dedicated EV manufacturing hub using fully automated production lines and 100% renewable energy. It features cutting-edge robotics, AI-driven quality control, and sustainable construction materials to minimize environmental impact.

When will the Georgia EV plant start production?

Production at the Hyundai Metaplant is scheduled to begin in Q4 2024, with initial output focused on the IONIQ 5 and future EV models. The facility is expected to reach full annual capacity of 300,000 vehicles by 2026.

How many jobs will the new Hyundai EV factory create?

The Georgia facility will create over 8,500 direct jobs and support thousands more in the regional supply chain. Hyundai is partnering with local schools to train workers in EV battery production and advanced manufacturing techniques.

What electric vehicles will be built at this new factory?

The new Hyundai electric car factory will initially produce the IONIQ 5 SUV and upcoming IONIQ 6 sedan, with capacity for future EV models. The flexible platform design allows quick adaptation to new battery and vehicle architectures.

Is the Hyundai Metaplant really carbon neutral?

Yes, the Georgia facility aims for carbon neutrality through solar panel installations, renewable energy purchases, and a closed-loop water recycling system. Hyundai plans to offset remaining emissions through verified carbon credit programs.