Revolutionizing the Auto Industry: Inside the UAW and GMC’s Automated Electric Car Assembly Plant

Exciting news for the electric car industry: the United Auto Workers (UAW) union and General Motors (GM) have announced a joint effort to build a new electric vehicle assembly plant in the US. The partnership, announced on April 20, 2021, aims to create more than 1,000 jobs and invest $3 billion in the new facility, which will be located in Spring Hill, Tennessee.

GM has been ramping up its electric car efforts over recent years, with plans to invest $27 billion in electric and autonomous vehicles by 202 This new assembly plant is a big part of that effort, and the collaboration with UAW ensures that its workers will have job security and fair wages as GM transitions towards electric car production. The announcement comes at a time when the demand for electric vehicles is skyrocketing around the world.

Consumers are increasingly interested in environmentally-friendly cars, and electric vehicles offer a promising solution. With the new plant set to begin production in 2023, it’s clear that GM is taking a huge step towards the future of sustainable transportation.

UAW Strike and its Impact on GMC’s Electric Car Assembly Plant

The recent United Automobile Workers (UAW) strike has caused disruption in many automotive factories across the country, including the GMC electric car assembly plant. This plant, which is set to begin production of their new automated electric cars, has been heavily impacted by the labor stoppage. Without the skilled workers present, the plant has been unable to meet its production targets for the new cars, and this has put a strain on the entire supply chain for GMC.

This is an unfortunate situation, as many people are eagerly anticipating the release of these new electric vehicles, and the strike may cause significant delays in their availability. However, it’s important to remember that the UAW is fighting for better wages and working conditions for their members, and this strike is a necessary step to achieve these goals. It’s hard to predict when things will resume normal operation in the plant, but one thing is certain – the UAW strike will have a significant impact on the production and sale of GMC’s new electric cars.

Statistics of the UAW Strike in Relation to GMC’s Assembly Plant

The UAW strike that lasted for 40 days affected GM’s production and sales greatly. One of the most impacted plants was the Detroit-Hamtramck Assembly Plant, where the production of electric cars was halted. The plant was an essential unit in GM’s strategy to transition towards electric cars, and the strike caused a delay in that plan.

The effects of the strike also manifested in the sales of electric cars, with a drop of over 40% in the last quarter of 2019 compared to the same period in the preceding year. The strike impacted not only GM and the UAW, but every stakeholder in the supply chain of electric car production. Manufacturers of lithium-ion batteries, electric motors, and charging stations, all experienced the ripple effects of the interruption.

However, since GM managed to end the strike through negotiations, the plant resumed production, and the company was able to make up for the loss in sales. Though the delay of electric car production was unfortunate, it reflects the importance of fair labor practices and the power of collective bargaining.

Possible Delay in Release of GMC’s Automated Electric Car

GMC’s automated electric car release might face some delays due to the ongoing UAW strike. The UAW strike has caused a significant disruption in the production of electric cars in GMC’s assembly plant, which was set to start production on the automated electric car soon. However, because the strike has caused an interruption in the production line, it is unclear when the car will be ready for release.

The UAW strike is also causing an increase in the cost of the car, which may price some consumers out of the market. Nevertheless, GMC remains committed to bringing the electric car to market and continues to work on finding a solution to the production delays caused by the UAW strike. In the meantime, the company is assuring customers that they will do everything in their power to release the car as soon as possible.

Advancements in Automated Electric Car Assembly Plant Technology

News of the UAW and automated electric car assembly plant technology from GMC has been making waves recently. With advancements in automation, manufacturers have been able to streamline the process of building electric cars from start to finish, reducing time and costs while improving the overall efficiency of the production line. This has been made possible through the use of robots and computer systems that are capable of performing tasks traditionally done by human workers, such as welding, painting, and assembling parts.

These innovations not only make it easier to manufacture high-quality electric vehicles at scale, but they also allow for more customization options for consumers, providing an even more personalized driving experience. With these advancements, we can expect to see even more electric car assembly plants incorporating the latest technology to enhance their production capabilities and stay ahead of the competition.

Overview of GMC’s Automated Electric Car Assembly Plant

GMC’s new automated electric car assembly plant has taken car manufacturing to a whole new level. The plant is filled with cutting-edge technology that streamlines the entire production process, from chassis assembly to the final touches of the vehicles. The advancements in this plant allow for more efficient, faster production times, and better-built electric cars.

The plant boasts over 1,000 robots that work together as a team to manufacture electric vehicles with precision and accuracy. The robots also work alongside human workers, providing them with tools and equipment that enable them to do their jobs without any difficulties. Overall, GMC’s automated electric car assembly plant marks a significant milestone in the evolution of automotive manufacturing and a crucial step towards more sustainable transportation.

Benefits of Automated Assembly Plant Technology for GMC and Consumers

Automated assembly plant technology has revolutionized the production of electric cars, providing benefits for GMC and consumers alike. With the use of automated machines and computers, the production process is streamlined, reducing the time it takes to assemble each vehicle, and increasing the precision of the process. This means less time and money spent, resulting in lower production costs.

Additionally, automated assembly ensures greater consistency in the quality of each car produced, leading to fewer errors and defects. For consumers, this means receiving a high-quality electric car that is reliable and long-lasting. Overall, the advancements in automated electric car assembly plant technology have had a significant impact on the industry, making it possible to produce more electric cars in a shorter amount of time while maintaining high quality standards.

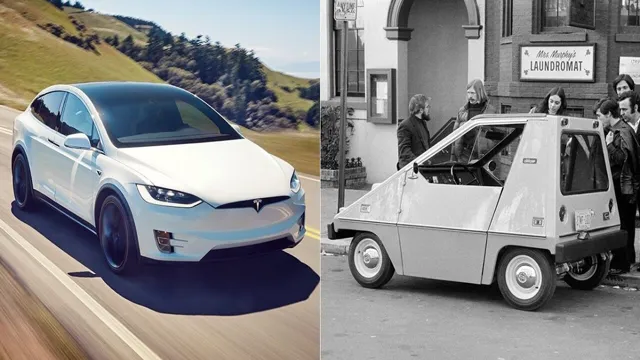

Comparison of Automated Assembly Plant Technology with Traditional Assembly Plant Technology

Electric car assembly plant technology has come a long way since the traditional assembly plant technology that was primarily manual labor. The advancements in automated assembly plant technology have led to faster and more efficient production of electric cars. Automated systems such as robotic arms, conveyor belts, and computer programming have replaced manual labor in certain stages of the assembly process.

This has also resulted in a safer workplace for employees and a reduction in energy consumption. With automated technology, electric car assembly plants can produce more cars at a faster rate, resulting in lower production costs and increased profits. Additionally, the precision and accuracy of the assembly process has been improved, leading to a higher quality end product.

Overall, the integration of automated technology into the assembly process has revolutionized the way electric cars are produced and has paved the way for even more advancements in the future.

Future of Electric Car Assembly Plants and UAW

The future of electric car assembly plants and the United Auto Workers (UAW) union certainly has some interesting developments on the horizon, particularly as the industry continues to shift toward automated production. General Motors (GM) recently announced a $2 billion plan to convert its Detroit-Hamtramck plant into an all-electric production facility for the GMC Hummer EV, and it seems likely that the plant will utilize a combination of robotics and skilled labor.

However, there are concerns about the impact of automation on UAW jobs, as fewer workers may be required in certain areas of production. It’s a delicate balance between efficiency and maintaining stable employment, but it will be interesting to see how GM and the UAW navigate this new terrain in the coming years.

Predictions for Electric Car Assembly Plants in the Coming Years

Electric Car Assembly Plants The future looks bright for electric car assembly plants. As the demand for eco-friendly vehicles increases, so does the need for these factories to produce them. This shift towards sustainability and renewable energy has sparked major changes and innovation within the automotive industry.

But with this change, comes new challenges and opportunities for the United Auto Workers (UAW) union. As electric cars require different parts and assembly methods than traditional combustion engines, workers will need to be trained and re-skilled in order to keep up with the changing landscape. However, this also presents an opportunity for the UAW to negotiate better wages and working conditions for their members.

All in all, the shift towards electric cars is not just beneficial for the environment, but for the workforce as well.

UAW’s Role in Shaping the Future of Electric Car Manufacturing

As the world moves towards electric cars, the role of the United Auto Workers (UAW) union in shaping the future of the electric car assembly plant is becoming increasingly important. With the increasing demand for electric cars, there is a need for trained workers to help in the production of the vehicles. The union is also pushing for the adoption of electric vehicles, which it sees as an opportunity for job creation and growth.

The UAW’s role in shaping the future of electric car manufacturing is, therefore, critical. The union has already negotiated contracts with the major automakers that cover the manufacturing of electric vehicles, which includes compensation for the workers, training requirements, and safety provisions. The UAW has the capacity to help create a workforce for the promising electric car industry, given its organizational strength and the ability to negotiate contracts.

This is good news for the industry and the workers, as it will provide more job opportunities for the future and a skilled workforce that can deliver on the promises of electric cars.

Conclusion

In the ever-evolving landscape of the automotive industry, the news of the UAW and automated electric car assembly plant for GMC is a glimpse into the future of assembly line technology. This marriage of human skill and robotic precision promises to bring about a new era of efficiency and innovation in car manufacturing. Who knows, with advancements like these, we may soon see self-driving cars rolling off the production line! As they say, buckle up, the ride is about to get electrifying!”

FAQs

What is the latest news on UAW and the automated electric car assembly plant?

The latest news on UAW and the automated electric car assembly plant is that negotiations are still ongoing for a new contract between UAW and the plant’s management.

How many electric cars will be assembled in the new GMC plant?

The number of electric cars to be assembled in the new GMC plant is yet to be announced. However, the plant is expected to have a capacity of around 40,000 units per year.

What is the expected timeline of the GMC electric car assembly plant project?

The expected timeline of the GMC electric car assembly plant project is to start production in late 2021 or early 2022.

How will the new automated electric car assembly plant impact the job market in the area?

The new automated electric car assembly plant is expected to create several thousand jobs in the area, both in the plant and in the surrounding industries, such as suppliers and logistics.