Ford Outsourcing on Electric Car What You Need to Know

Featured image for on electric car what is ford outsourcing

Image source: imgv2-2-f.scribdassets.com

Ford is aggressively outsourcing key components of its electric vehicle production—including battery manufacturing, software development, and assembly—to accelerate its EV transition and cut costs. By partnering with global suppliers and tech firms, Ford aims to scale quickly while focusing on design, branding, and core innovation. This strategic shift highlights how legacy automakers are redefining competitiveness in the electric era.

Key Takeaways

- Ford outsources EV production to boost efficiency and reduce costs.

- Key partnerships include SK Innovation for battery manufacturing and tech.

- Outsourcing speeds up innovation by leveraging third-party expertise.

- Focus remains on core competencies like design and branding.

- Global supply chains are critical for Ford’s EV scalability and success.

📑 Table of Contents

- Why Ford Is Turning to Outsourcing in the Electric Car Revolution

- What Exactly Is Ford Outsourcing in the EV Space?

- Why Ford Is Choosing Outsourcing Over Going It Alone

- Real-World Examples: Ford’s Key EV Outsourcing Partnerships

- Potential Downsides and Challenges of Ford’s Outsourcing Strategy

- What This Means for Consumers: Pros, Cons, and Tips

- Data Snapshot: Ford’s EV Outsourcing at a Glance

- The Road Ahead: Is Ford’s Outsourcing Strategy a Winner?

Why Ford Is Turning to Outsourcing in the Electric Car Revolution

Let’s be honest—watching Ford, a century-old American automotive giant, shift gears into the electric vehicle (EV) era feels a little like seeing your grandpa pick up skateboarding. It’s bold, a little unexpected, and honestly, kind of inspiring. But here’s the thing: Ford isn’t going it alone. In fact, Ford outsourcing on electric car development, manufacturing, and tech is one of the most strategic moves the company has made in decades. And if you’re an EV enthusiast, an investor, or just curious about where the auto industry is headed, this shift matters—a lot.

You might be thinking, “Wait, Ford? The same company that built the Model T and the F-150? Why would they need help making electric cars?” Great question. The truth is, building EVs isn’t just about swapping an engine for a battery. It’s a whole new ballgame. From battery chemistry and software to charging infrastructure and global supply chains, the EV world is fast, complex, and fiercely competitive. And Ford, like many legacy automakers, realized it couldn’t master everything in-house—not fast enough, anyway. So, they started outsourcing. And not just a little. A lot. In this post, we’ll break down exactly what Ford is outsourcing on electric cars, why they’re doing it, and what it means for you—the driver, the buyer, the future of mobility.

What Exactly Is Ford Outsourcing in the EV Space?

When we say “Ford outsourcing on electric car,” it’s not just one thing. It’s a multi-layered strategy touching nearly every part of the EV ecosystem. Think of it like a recipe: Ford still owns the kitchen and the brand, but they’re hiring top chefs for certain ingredients. Let’s dive into the key areas where Ford is partnering with outside experts.

Visual guide about on electric car what is ford outsourcing

Image source: prestigeelectriccar.com

Battery Technology and Production

One of the biggest challenges in EVs? Batteries. They’re expensive, complex, and require rare earth materials. Ford doesn’t want to build its own battery factories from scratch—at least not entirely. Instead, they’ve formed a joint venture with SK On, a South Korean battery giant, to build three massive “BlueOval SK” battery plants in the U.S. (in Kentucky and Tennessee). These facilities will produce lithium-ion batteries for the Ford F-150 Lightning, the Mustang Mach-E, and future models.

By outsourcing battery production (well, co-owning it), Ford avoids the massive capital investment and technical hurdles of building gigafactories solo. It’s like opening a restaurant but letting a top-tier bakery handle the bread. You get the quality without the headache.

Software and Infotainment Systems

Modern EVs are basically computers on wheels. Ford’s SYNC infotainment system used to be developed mostly in-house, but with the rise of EVs, they’ve turned to external partners. For example, Ford is working with Google to integrate Google’s Android Automotive OS into upcoming models like the 2024 Ford Explorer EV. This means Google handles the operating system, voice assistant (Google Assistant), and app integration—freeing Ford to focus on vehicle performance and design.

Another example: Ford partnered with Qualcomm to use their Snapdragon Digital Chassis platform for connectivity, over-the-air (OTA) updates, and advanced driver assistance systems (ADAS). This is a big deal. Instead of spending years building software from scratch, Ford gets cutting-edge tech ready to go—faster and more reliably.

Charging Infrastructure and Partnerships

You can build the best EV in the world, but if owners can’t charge it easily, they won’t buy it. That’s why Ford is outsourcing charging solutions. They’ve teamed up with Tesla to allow Ford EV owners to use Tesla Superchargers via an adapter starting in 2024. This gives Ford access to over 12,000 Superchargers in North America—without building their own network from scratch.

Additionally, Ford is working with Electrify America and EVgo to offer free charging credits and seamless payment integration. This “outsourced” charging strategy reduces Ford’s infrastructure burden while giving customers more flexibility.

Why Ford Is Choosing Outsourcing Over Going It Alone

You might be wondering: Why not just build everything in-house? After all, Ford has the factories, the engineers, and the brand trust. But the EV race isn’t about pride—it’s about speed, cost, and innovation. Let’s break down the real reasons Ford is betting big on outsourcing.

Speed to Market: Beating the Competition

The EV market is moving at lightning speed. Tesla, Rivian, BYD, and even tech companies like Apple are all racing to dominate. Ford can’t afford to spend 5–10 years developing a battery tech or software platform. By outsourcing, they can launch competitive EVs in half the time.

Take the Mustang Mach-E. It launched in 2020 with strong tech and performance, but Ford didn’t build the battery or software stack alone. They leveraged existing partnerships to get it to market fast. That’s the power of outsourcing: agility.

Cost Efficiency and Risk Mitigation

Building a battery gigafactory can cost $1–2 billion. Developing a new operating system? Millions more. And if the tech becomes obsolete in two years? That’s a huge loss. By outsourcing, Ford shares the financial risk.

For example, the BlueOval SK joint venture splits the cost and risk with SK On. If battery demand drops, Ford isn’t stuck with a billion-dollar white elephant. This “shared risk” model is a smart move in a volatile market.

Access to Expertise and Innovation

Let’s face it: Ford’s core strength is building trucks and cars—not software or battery chemistry. By partnering with Google, Qualcomm, and SK On, Ford gains access to world-class talent and R&D that would take years to develop internally.

It’s like a football team hiring a star quarterback instead of trying to train their own. You get immediate performance boosts without the long development curve.

Focus on Core Competencies

Ford’s real magic lies in vehicle design, manufacturing, and brand loyalty—especially in the U.S. truck market. By outsourcing the “non-core” EV components, they can double down on what they do best: building tough, reliable, desirable vehicles.

This is a classic focus strategy. Don’t try to be good at everything. Be great at what matters most.

Real-World Examples: Ford’s Key EV Outsourcing Partnerships

Let’s look at some concrete examples of how Ford’s outsourcing strategy is playing out in real life. These aren’t just press releases—they’re vehicles you can see, drive, and buy today.

BlueOval SK: The Battery Powerhouse

As mentioned, Ford and SK On are investing $11.4 billion to build three battery plants. The first, in Kentucky, will produce batteries for the F-150 Lightning starting in 2025. These batteries use SK On’s advanced nickel-cobalt-manganese (NCM) chemistry, offering longer range and faster charging than older tech.

Why this matters: Without this partnership, Ford might have delayed the Lightning by years. Now, they can scale production quickly and meet growing demand.

Google’s Android Automotive in the 2024 Explorer EV

Starting in 2024, the Ford Explorer EV will run on Google’s Android Automotive OS. This means built-in Google Maps, Assistant, and Play Store apps—no need to connect your phone. Ford handles the car; Google handles the digital experience.

For drivers, this means a seamless, familiar interface. For Ford, it means fewer software bugs and faster updates. Win-win.

Tesla Supercharger Access: A Game-Changer

In May 2023, Ford announced a deal allowing F-150 Lightning and Mustang Mach-E owners to use Tesla Superchargers with an adapter. This gives Ford EV drivers access to Tesla’s reliable, widespread network—something no other non-Tesla brand had before.

Tip: If you’re considering a Ford EV, this is a huge perk. Long road trips just got a lot less stressful.

Qualcomm’s Snapdragon Platform in the Ford Pro EVs

Ford’s commercial EV lineup, including the E-Transit van, uses Qualcomm’s Snapdragon Digital Chassis. This enables real-time fleet tracking, OTA updates, and advanced safety features. It’s a smart move for business customers who need reliability and connectivity.

Fun fact: This platform can even predict maintenance needs—saving companies time and money.

Potential Downsides and Challenges of Ford’s Outsourcing Strategy

Now, let’s be real: outsourcing isn’t all sunshine and rainbows. There are risks, trade-offs, and potential pitfalls. As a consumer, it’s important to understand both sides.

Loss of Control Over Key Technologies

When Ford outsources software to Google or batteries to SK On, they give up some control. If Google changes its OS roadmap, or SK On faces supply chain issues, Ford’s EVs could suffer.

Example: In 2022, a software bug in the Mustang Mach-E’s SYNC system caused infotainment freezes. While Ford fixed it, the root cause was tied to third-party code—highlighting the risk of dependency.

Brand Consistency and User Experience

When different partners handle different parts of the car, the user experience can feel fragmented. Imagine driving a Ford, but the voice assistant sounds like Google, the navigation is Apple Maps (if they partner with Apple in the future), and the charging network is Tesla’s. It might work, but does it feel like a “Ford” experience?

Tip: Test drive a Ford EV and pay attention to how smoothly the software, charging, and voice features integrate. A disjointed experience can be a dealbreaker.

Long-Term Dependency on Partners

If Ford becomes too reliant on outsourcing, they might struggle to innovate independently in the future. What if SK On stops making batteries? What if Google raises licensing fees? These are real risks.

Ford is aware of this. That’s why they’re also investing in in-house R&D for solid-state batteries and AI-driven features. It’s a balance: outsource to move fast, but keep some core tech in-house to stay in control.

Data Privacy Concerns

When Google handles your car’s software, they also collect data—your location, driving habits, voice commands. Ford says they anonymize and protect data, but some consumers are wary.

Ask yourself: Are you comfortable with Google knowing your daily commute? If not, look for models with more Ford-controlled software (though they’re becoming rare).

What This Means for Consumers: Pros, Cons, and Tips

So, how does Ford’s outsourcing strategy affect you? Whether you’re buying an EV, leasing, or just curious, here’s what you need to know.

Pros for You as a Buyer

- Better tech, faster: You get cutting-edge software, batteries, and charging access without waiting years.

- More charging options: Tesla Supercharger access means fewer range anxiety headaches.

- Lower prices (eventually): Shared costs mean Ford can keep EV prices competitive.

- Reliability boosts: Partners like SK On and Qualcomm have proven track records in tech and manufacturing.

Cons and Watch-Outs

- Software bugs: Third-party code can introduce glitches. Always check recent owner reviews.

- Less customization: If the OS is Google’s, you can’t tweak it like a Ford-built system.

- Long-term support: If a partner exits the EV space, will Ford keep supporting the tech?

- Warranty complexity: Battery issues? Software bugs? You might need to contact multiple companies.

Practical Tips When Buying a Ford EV

- Ask about the battery source: Is it from BlueOval SK? That’s good. If it’s from a lesser-known supplier, dig deeper.

- Test the software: Spend 15 minutes in the infotainment system. Is it fast? Bug-free? Does it feel like a Ford?

- Check charging compatibility: Confirm if your model gets Tesla Supercharger access and how the adapter works.

- Look at OTA update history: Has Ford been pushing regular updates? That shows commitment to software quality.

- Consider the long-term: Will Ford still support this car in 5–10 years, or will they shift focus?

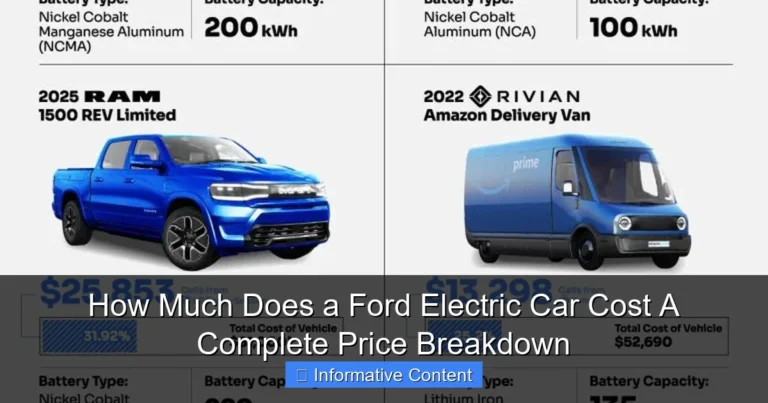

Data Snapshot: Ford’s EV Outsourcing at a Glance

| Partner | Area | Key Benefit | Ford Model(s) Affected |

|---|---|---|---|

| SK On | Battery production | High-capacity, fast-charging batteries | F-150 Lightning, Mustang Mach-E, future EVs |

| Software/OS | Seamless Android integration, Google Assistant | 2024 Explorer EV, future models | |

| Tesla | Charging network | Access to 12,000+ Superchargers | F-150 Lightning, Mustang Mach-E (2024+) |

| Qualcomm | Connectivity/ADAS | OTA updates, fleet management | E-Transit, Ford Pro EVs |

| Electrify America | Charging credits | Free charging for new buyers | All Ford EVs (varies by model) |

The Road Ahead: Is Ford’s Outsourcing Strategy a Winner?

So, is Ford’s decision to outsource key parts of its electric car strategy a smart move? In short: yes, but with caveats. The benefits are clear—faster innovation, lower costs, and access to world-class tech. For a legacy automaker trying to catch up in the EV race, outsourcing is not just a shortcut; it’s a survival tool.

But here’s the thing: outsourcing only works if Ford maintains strong oversight. They can’t just hand over the keys and hope for the best. The real test will be in the next 3–5 years. Will the partnerships deliver reliable, high-quality EVs? Will Ford keep improving the user experience, even when parts of it aren’t theirs? And most importantly, will consumers still feel like they’re driving a Ford?

As a driver, I’m cautiously optimistic. The F-150 Lightning is a beast, the Mach-E is stylish and fun, and the charging access is a game-changer. But I’ll also be watching for software updates, battery longevity, and how Ford handles any hiccups with their partners.

Bottom line: Ford outsourcing on electric car isn’t a sign of weakness—it’s a sign of wisdom. In a world where speed and innovation rule, sometimes the best way to lead is to collaborate. And if Ford can pull this off, we might just see the Blue Oval not just survive the EV era—but thrive in it.

So, the next time you see a Ford EV on the road, remember: under the hood, it’s not just Ford. It’s a global team of experts, all working together to power the future. And that? That’s pretty exciting.

Frequently Asked Questions

Why is Ford outsourcing parts of its electric car production?

Ford is outsourcing certain components of its electric car manufacturing to specialized suppliers to reduce costs, accelerate innovation, and focus on core competencies like design and software integration. This strategy helps Ford compete more effectively in the rapidly growing EV market.

Which parts of Ford’s electric cars are being outsourced?

Ford outsources key EV components like battery cells, power electronics, and software systems to partners like SK Innovation and Google. However, it retains in-house control over final assembly, vehicle architecture, and brand-specific technologies.

Is Ford outsourcing on electric car development a smart move?

Yes, outsourcing allows Ford to leverage cutting-edge expertise from suppliers while reducing R&D costs. This approach shortens time-to-market for new EVs like the F-150 Lightning and Mustang Mach-E.

How does Ford ensure quality when outsourcing electric car technology?

Ford maintains strict quality standards through rigorous supplier audits, long-term partnerships, and co-developed specifications. Each outsourced component undergoes testing to meet Ford’s safety and performance requirements.

Does Ford’s outsourcing affect electric car pricing?

Outsourcing helps Ford optimize costs, which can lead to more competitive pricing for EVs. However, final vehicle costs also depend on material prices, tariffs, and supply chain logistics.

What are the risks of Ford outsourcing on electric car innovation?

Over-reliance on suppliers may limit Ford’s control over supply chains and proprietary tech. However, the company mitigates risks through diversified partnerships and strategic in-house R&D investments.