Rezvani 3D Printed Innovation in Automotive Design

Featured image for rezvani 3d printed

Image source: wallpaperaccess.com

Rezvani is revolutionizing automotive design with cutting-edge 3D printing technology, enabling unparalleled customization, rapid prototyping, and lightweight performance parts. By integrating 3D printed components into their high-performance vehicles, Rezvani delivers futuristic aesthetics, enhanced durability, and faster production cycles, setting a new benchmark in the luxury automotive space.

Key Takeaways

- 3D printing accelerates Rezvani’s prototyping and production timelines significantly.

- Customization reaches new levels with Rezvani’s 3D-printed bespoke components.

- Lightweight materials enhance performance and fuel efficiency in Rezvani vehicles.

- Complex geometries enabled by 3D printing improve structural integrity and design.

- Sustainability improves through reduced waste and optimized material usage.

- Cost-effective low-volume production becomes viable with Rezvani’s 3D approach.

📑 Table of Contents

- Rezvani 3D Printed Innovation in Automotive Design

- What Is 3D Printing and Why Is It a Game-Changer for Cars?

- Rezvani’s Approach to 3D Printed Automotive Design

- Materials and Technologies Behind Rezvani’s 3D Printing Success

- Real-World Examples: Rezvani Models Using 3D Printed Components

- Challenges and Considerations in 3D Printed Automotive Manufacturing

- Data Table: Rezvani 3D Printed Components by Model

- The Road Ahead: Rezvani and the Future of 3D Printed Cars

Rezvani 3D Printed Innovation in Automotive Design

Imagine walking into a garage where the car on the lift isn’t just being repaired—it’s being reimagined. That’s the world Rezvani Motors has stepped into, and it’s not just about flashy exteriors or roaring engines. It’s about how a company, known for its bold, high-performance vehicles, is now pushing the boundaries of automotive manufacturing with a tool that sounds like it’s from the future: 3D printing.

When you hear “3D printed car,” your mind might jump to a sci-fi movie or a prototype that never makes it to the street. But Rezvani is changing that narrative. They’re not just dabbling in additive manufacturing—they’re integrating it into real-world vehicle production. And they’re doing it in ways that are both practical and revolutionary. From custom body panels to performance-enhancing components, Rezvani’s use of 3D printing is more than a gimmick. It’s a strategic shift that’s redefining what’s possible in automotive design, customization, and sustainability. Whether you’re a car enthusiast, a tech lover, or someone who just wants to know how the future of driving is being built, this is a story worth following.

What Is 3D Printing and Why Is It a Game-Changer for Cars?

Let’s start with the basics. 3D printing, or additive manufacturing, is a process where a digital 3D model is turned into a physical object by layering material—plastic, metal, or even carbon fiber—one thin slice at a time. Think of it like a high-tech version of a printer, but instead of ink on paper, it’s building tangible parts from the ground up.

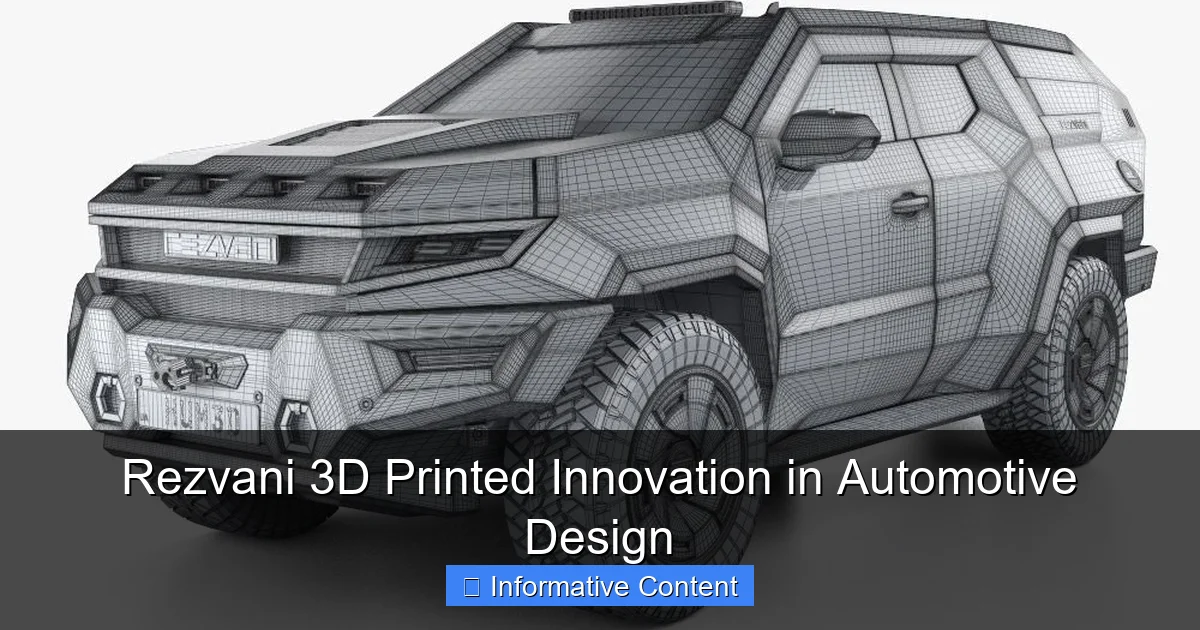

Visual guide about rezvani 3d printed

Image source: wallpapercave.com

How 3D Printing Works in Automotive Applications

In traditional car manufacturing, parts are made using molds, stamping, and machining. These methods are great for mass production but come with high upfront costs and long lead times. 3D printing flips that model on its head. Instead of needing expensive tooling, you just need a digital file and a printer. That means:

- Parts can be produced on-demand, reducing inventory costs.

- Complex shapes that were once impossible or too costly can now be made.

- Customization is faster and more affordable.

- Less material waste—only what’s needed is used.

For a company like Rezvani, which builds low-volume, high-performance vehicles like the Rezvani Tank and Rezvani Beast, this is a perfect fit. They don’t need to make 100,000 fenders. They need 50—maybe with different colors, textures, or aerodynamic tweaks for each customer. 3D printing makes that not only possible but efficient.

From Prototype to Production: The Evolution

Initially, 3D printing was used mostly for rapid prototyping—quickly building a model to test fit, form, and function. But today, thanks to advances in materials and printer precision, many 3D printed parts are strong enough for actual use on the road. Rezvani isn’t just printing mock-ups; they’re installing functional, durable components that handle real-world stress.

For example, the Rezvani Tank uses 3D printed air ducts, sensor housings, and even interior trim pieces. These aren’t decorative—they’re engineered to meet strict safety and performance standards. The company even uses metal 3D printing for high-stress components like suspension brackets, which need to withstand extreme forces without adding unnecessary weight.

Tip: If you’re curious about 3D printing for your own projects, start small. A desktop 3D printer can help you understand the process, materials, and design constraints. But for automotive-grade parts, you’ll need industrial-grade equipment—something Rezvani has invested in heavily.

Rezvani’s Approach to 3D Printed Automotive Design

Rezvani doesn’t just use 3D printing as a side project. It’s a core part of their design and production philosophy. Their approach is a blend of art, engineering, and innovation—focused on delivering vehicles that are not only powerful but also uniquely tailored to each driver.

Customization at Scale: One Car, One Identity

One of the biggest advantages of Rezvani 3D printed components is the ability to offer deep customization. Imagine ordering a car where the grille, side vents, or even dashboard accents are designed just for you. With traditional manufacturing, that would require custom tooling and cost thousands. With 3D printing? It’s just a new file and a few hours of printing.

Rezvani offers customers the chance to co-design certain exterior and interior elements. For instance, a client might request a grille inspired by their favorite geometric pattern or a steering wheel with a personalized texture. These aren’t off-the-shelf options—they’re digitally modeled and printed to spec. The result? A car that feels like an extension of the owner’s personality.

Speed and Agility in Development

Car development is traditionally slow. Design changes can take months to implement. But with 3D printing, Rezvani can iterate quickly. If a designer wants to test a new front splitter for better aerodynamics, they can print a version in 24 hours, test it on the track, and make adjustments—all without touching a mold.

This agility is especially valuable for Rezvani, which often introduces new models or special editions (like the Rezvani Vengeance or the Beast X). Instead of waiting for a factory to retool, they can prototype, refine, and produce small batches in-house. That means faster time-to-market and more responsive design cycles.

Lightweighting for Performance

Every ounce matters in performance cars. The lighter the vehicle, the faster it accelerates, the better it handles, and the more efficient it becomes. 3D printing allows Rezvani to design parts with internal lattice structures—complex, honeycombed patterns that are strong but use less material.

For example, a 3D printed control arm (a part that connects the wheel to the suspension) can be 30% lighter than a traditional cast metal version, without sacrificing strength. This kind of Rezvani 3D printed innovation directly translates to better performance on the road or track.

Tip: If you’re building a custom car or modifying a vehicle, consider 3D printing for non-structural parts like trim, badges, or interior organizers. It’s a low-risk way to add personal flair without compromising safety.

Materials and Technologies Behind Rezvani’s 3D Printing Success

Not all 3D printing is the same. The magic lies in the materials and the machines. Rezvani uses a mix of advanced technologies to ensure their printed parts meet the high standards of the automotive industry.

Industrial-Grade 3D Printers: The Tools of the Trade

Rezvani relies on industrial 3D printers like those from Markforged, HP, and Stratasys. These aren’t your average desktop machines. They’re built for precision, durability, and speed. For example:

- Markforged X7: Uses continuous carbon fiber reinforcement to print parts as strong as aluminum.

- HP Multi Jet Fusion: Delivers high-resolution plastic parts ideal for interior and aerodynamic components.

- Stratasys F900: Handles large-format printing, perfect for full-size body panels or molds.

These printers can produce parts with tolerances as tight as ±0.1 mm—critical for fit and function in a moving vehicle.

Advanced Materials: From Plastic to Metal

The materials used in Rezvani’s 3D printing process are carefully selected for their strength, weight, and thermal properties. Here’s a breakdown of the key materials:

- Onyx (nylon with carbon fiber): Used for interior trim, brackets, and housings. Strong, heat-resistant, and lightweight.

- Carbon Fiber Reinforced Polymers (CFRP): For structural parts like air intakes and suspension components. Combines strength with minimal weight.

- Stainless Steel and Titanium (via metal 3D printing): For high-stress parts like engine mounts or exhaust components. These are printed using Direct Metal Laser Sintering (DMLS) and can withstand extreme temperatures and forces.

- Thermoplastic Polyurethane (TPU): Used for flexible seals, gaskets, and vibration-damping elements.

One standout example is the Rezvani Beast’s 3D printed intake manifold. Made from a high-temperature polymer, it’s 20% lighter than the original aluminum version and improves airflow efficiency. That means more power from the same engine.

Post-Processing: Making Printed Parts Road-Ready

Just printing a part isn’t enough. Rezvani uses post-processing techniques to ensure durability and finish:

- Sanding and Polishing: For smooth, showroom-quality surfaces.

- Heat Treatment: To relieve internal stresses in metal parts.

- Coating and Painting: To match OEM standards and protect against UV and weather.

- Quality Testing: Each part undergoes stress tests, dimensional checks, and real-world simulations.

This attention to detail ensures that every Rezvani 3D printed component isn’t just innovative—it’s reliable.

Real-World Examples: Rezvani Models Using 3D Printed Components

Let’s look at how Rezvani puts their 3D printing strategy into action across their vehicle lineup. These aren’t theoretical concepts—they’re cars you can see, touch, and even drive.

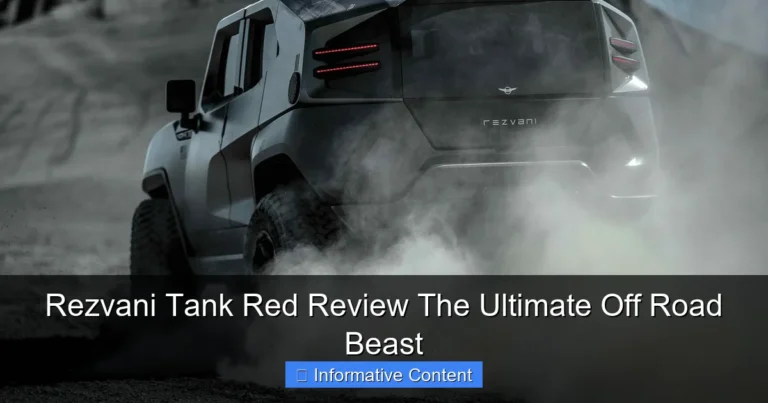

Rezvani Tank: Rugged, Custom, and Tech-Driven

The Rezvani Tank is a military-inspired SUV with a civilian twist. It’s armored, off-road capable, and packed with tech. But what many don’t realize is that over 15% of its non-structural components are 3D printed.

- Front and Rear Bumpers: Custom designs with integrated lighting and airflow channels, printed in high-impact polymer.

- Sensor Housings: For the vehicle’s night vision, laser warning, and thermal imaging systems—printed to exact specs for perfect fit.

- Interior Trim: Personalized dash inserts, door panels, and even 3D printed speaker grilles with unique patterns.

One customer even requested a grille shaped like a lion’s head—something impossible with traditional stamping. With 3D printing, Rezvani delivered it in a week.

Rezvani Beast: Lightweight Performance Redefined

The Beast is a supercar built for speed and agility. Every gram counts. Rezvani uses 3D printing to shave weight and boost performance:

- Intake System: 3D printed air ducts and manifold improve airflow and reduce turbulence.

- Interior Components: Custom steering wheel grips, gear shifters, and seat frames printed with lattice structures.

- Aerodynamic Add-Ons: Rear spoilers, side skirts, and diffusers printed with internal cooling channels.

The result? A car that’s not only faster but also more efficient and easier to repair. If a part gets damaged, Rezvani can print a replacement in hours, not weeks.

Rezvani Vengeance: The Future of SUV Design

The Vengeance is Rezvani’s answer to the luxury off-roader. It combines rugged capability with high-end comfort. 3D printing plays a key role in both areas:

- Customizable Exterior: Customers can choose from multiple 3D printed grille styles, fender flares, and roof rails.

- Modular Interior: 3D printed storage bins, cup holders, and console inserts that can be swapped out or redesigned.

- Lighting Elements: Unique LED housings with intricate, organic shapes that would be impossible with injection molding.

These features make the Vengeance not just a vehicle, but a platform for personal expression.

Challenges and Considerations in 3D Printed Automotive Manufacturing

As exciting as Rezvani 3D printed innovation is, it’s not without its hurdles. Let’s be honest—no technology is perfect, and 3D printing in cars comes with real challenges.

Cost and Scalability

While 3D printing reduces tooling costs, the printers themselves are expensive—often over $100,000. Plus, industrial materials like carbon fiber or titanium powder can cost hundreds of dollars per kilogram. For low-volume production, it’s cost-effective. But for mass-market cars? Not yet.

Rezvani’s niche market helps here. They’re not trying to compete with Toyota or Ford. They’re building high-end, low-volume vehicles where customization and innovation justify the cost. But for wider adoption, the industry needs cheaper materials and faster print speeds.

Regulatory and Safety Hurdles

Not every 3D printed part can be used on the road. Safety-critical components (like steering or braking systems) must meet strict government standards. While Rezvani uses 3D printing for many parts, they still rely on traditional methods for the most critical systems.

However, the tide is turning. Organizations like SAE (Society of Automotive Engineers) are developing standards for 3D printed automotive parts. As these evolve, we’ll likely see more printed components in safety roles.

Design Limitations and Material Trade-Offs

3D printing allows for incredible design freedom, but it’s not magic. Some shapes are hard to print, and some materials have limitations:

- Metal parts can be brittle if not printed correctly.

- Plastic parts may degrade in UV or high-heat environments.

- Large parts may warp during printing due to thermal stress.

Rezvani addresses these through rigorous testing and design optimization. For example, they use simulation software to predict how a part will behave under stress before printing it. It’s a smart approach that balances innovation with reliability.

Environmental Impact: A Double-Edged Sword

3D printing is often touted as eco-friendly because it reduces waste. And it does—by up to 90% compared to machining. But there are downsides:

- Some plastics used in printing are not biodegradable.

- Metal powder production is energy-intensive.

- Post-processing (like sanding and painting) can create emissions.

Rezvani is working to offset this by recycling unused powder, using renewable energy in their facility, and exploring bio-based polymers. It’s a step in the right direction, but sustainability remains a work in progress.

Data Table: Rezvani 3D Printed Components by Model

| Vehicle Model | 3D Printed Components | Material Used | Benefit |

|---|---|---|---|

| Rezvani Tank | Front bumper, sensor housings, interior trim | Onyx, CFRP, TPU | Customization, durability, reduced weight |

| Rezvani Beast | Intake manifold, steering wheel, seat frames | High-temp polymer, carbon fiber | Improved airflow, lighter weight, better handling |

| Rezvani Vengeance | Grille, roof rails, LED housings | Stainless steel, Onyx | Unique styling, modular design, corrosion resistance |

| Beast X (Special Edition) | Aerodynamic body kit, custom badges | Carbon fiber, nylon | Enhanced downforce, personalization |

The Road Ahead: Rezvani and the Future of 3D Printed Cars

Rezvani’s journey with 3D printing is just getting started. What began as a way to speed up prototyping has evolved into a full-fledged design and production strategy. And the implications go far beyond one company.

We’re entering an era where cars are no longer just machines—they’re digital experiences. With 3D printing, the line between design, manufacturing, and ownership is blurring. Imagine ordering a car online, customizing every detail, and having it delivered with parts printed to your exact specs. That future isn’t far off, and Rezvani is helping to build it.

But more than that, Rezvani is proving that innovation doesn’t require a massive factory. It can happen in a small shop with a few printers, a great team, and a bold vision. They’re showing the automotive world that the future isn’t just about electric powertrains or self-driving tech—it’s also about how we build the vehicles themselves.

So the next time you see a Rezvani on the road, don’t just admire the design. Think about the technology underneath—the layers of material, the digital precision, the human creativity. That car wasn’t just assembled. It was grown. And it’s a glimpse of what’s possible when you combine passion, engineering, and Rezvani 3D printed innovation.

Whether you’re a gearhead, a tech lover, or just someone who appreciates a well-made thing, this is a movement worth watching. The road ahead is 3D printed—and it’s going to be a wild ride.

Frequently Asked Questions

What is Rezvani 3D printed innovation in automotive design?

Rezvani 3D printed innovation refers to the brand’s cutting-edge use of additive manufacturing to create lightweight, high-performance vehicle components. This approach allows for faster prototyping, customization, and improved aerodynamics in models like the Rezvani Vengeance and Tank.

How does Rezvani use 3D printing in their cars?

Rezvani leverages 3D printing to produce complex parts such as custom body panels, interior trims, and aerodynamic elements. This technology reduces weight while maintaining strength, enhancing both performance and fuel efficiency.

Are Rezvani 3D printed vehicles more expensive than traditional models?

While Rezvani 3D printed models may have a higher upfront cost due to advanced technology, they offer long-term value through reduced maintenance, improved efficiency, and exclusive customization. The price reflects the innovation and craftsmanship involved.

What materials does Rezvani use for 3D printing?

Rezvani uses high-grade materials like carbon fiber-reinforced polymers, titanium, and aerospace-grade aluminum in their 3D printed components. These materials ensure durability, lightweight construction, and resistance to extreme conditions.

Can I customize my Rezvani with 3D printed features?

Yes, Rezvani offers extensive customization options using 3D printing, from personalized interior details to bespoke body kits. Customers can tailor designs to their preferences, making each vehicle uniquely theirs.

Is Rezvani leading the future of 3D printed automotive design?

Absolutely. Rezvani’s integration of 3D printing sets a benchmark for innovation, combining performance, luxury, and sustainability. Their work paves the way for mainstream adoption of additive manufacturing in high-end automotive production.