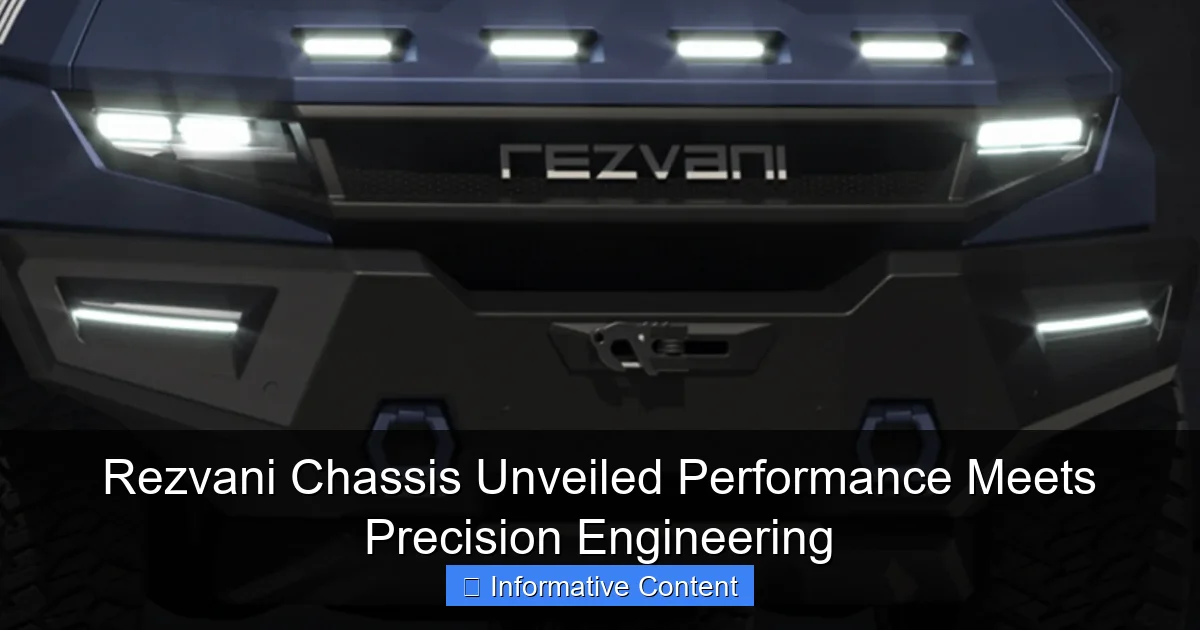

Rezvani Chassis Unveiled Performance Meets Precision Engineering

Featured image for rezvani chassis

Image source: images.squarespace-cdn.com

The Rezvani Chassis redefines high-performance engineering with a lightweight, aerospace-grade aluminum design that delivers unmatched rigidity and agility. Built for extreme precision and durability, it seamlessly integrates cutting-edge suspension and aerodynamics to elevate both track dominance and on-road control. This is the foundation of Rezvani’s relentless pursuit of automotive excellence.

Key Takeaways

- Unmatched rigidity: Rezvani chassis delivers superior structural strength for high-performance driving.

- Lightweight design: Advanced materials reduce weight without compromising durability or safety.

- Precision handling: Engineered for razor-sharp response and track-ready control.

- Custom integration: Seamlessly supports high-output powertrains and advanced suspension systems.

- Race-proven tech: Developed using motorsport-grade engineering for street and track use.

- Enhanced safety: Reinforced construction improves crash protection and driver confidence.

📑 Table of Contents

- The Birth of a Beast: Rezvani Chassis Unveiled

- Engineering the Foundation: Core Design Philosophy

- Performance on the Road: How the Chassis Delivers

- Materials and Manufacturing: The Craftsmanship Behind the Chassis

- The Rezvani Chassis in Action: Model-Specific Insights

- Data Table: Key Chassis Specifications Across Models

- The Verdict: A Chassis Built for Enthusiasts

The Birth of a Beast: Rezvani Chassis Unveiled

Imagine this: you’re driving down a winding coastal road, the sun glinting off the ocean, and your car feels like an extension of your body. It responds instantly to every subtle input, every curve, every straightaway. That’s the magic of a well-engineered chassis – the unsung hero that transforms a car from a machine into an experience. Now, enter Rezvani chassis – a name that’s rapidly gaining traction in the performance car world, promising a blend of raw power and surgical precision. I recently had the chance to dive deep into what makes Rezvani’s approach so unique, and let me tell you, it’s not just about horsepower. It’s about the foundation.

For years, I’ve been obsessed with the idea of a “perfect” driving experience. Not just speed, but control, feedback, and that elusive feeling of connection to the road. I’ve driven everything from vintage muscle cars to modern supercars, and while each has its charms, the chassis always felt like a compromise. Either too soft, sacrificing handling for comfort, or too stiff, punishing you for every bump. Rezvani seems to be tackling this head-on, building their chassis from the ground up with a clear focus on performance, durability, and, dare I say, driver enjoyment. What sets them apart? Let’s pull back the curtain and explore the engineering marvel that is the Rezvani chassis, from its innovative materials to its real-world performance. This isn’t just another car review; it’s a deep dive into the bones of a beast.

Engineering the Foundation: Core Design Philosophy

The heart of any high-performance vehicle lies beneath the skin – the chassis. For Rezvani, this isn’t an afterthought; it’s the starting point. Their core philosophy revolves around creating a platform that’s not just strong, but *smartly* strong, prioritizing specific performance characteristics over generic rigidity. This approach is evident in several key areas.

Visual guide about rezvani chassis

Image source: images.squarespace-cdn.com

The “Lightweight, Not Fragile” Paradox

Rezvani understands that weight is the enemy of performance, but they also recognize that “light” doesn’t have to mean “flimsy.” They’ve moved beyond traditional steel monocoques, embracing advanced materials to achieve a remarkable balance. Think of it like building a racehorse: you want a lean, powerful frame, not a fragile bird. The primary strategy? Strategic use of **aluminum and high-strength steel**. The main load-bearing structures, like the passenger safety cell, utilize high-strength steel for its exceptional crashworthiness and torsional rigidity. This provides a robust, safe foundation. Then, non-structural body panels, hoods, and even some suspension mounting points are crafted from lightweight aluminum. This targeted approach shaves off significant pounds without compromising structural integrity. For example, in the Rezvani Tank SUV, the aluminum hood alone saves over 40 lbs compared to a steel equivalent, contributing to a lower center of gravity and improved handling. It’s a classic case of “right material, right place.” The result? A chassis that feels nimble and responsive, not heavy and ponderous, while still offering the safety net of a steel safety cage. A practical tip for enthusiasts? When evaluating any performance car, look beyond the headline “lightweight” claims. Ask *how* they achieve it. Is it just thin steel (which can flex), or is it a calculated mix of advanced materials like Rezvani’s approach?

Modular Architecture: Flexibility Meets Performance

One of the most innovative aspects of the Rezvani chassis is its modular design. Unlike some manufacturers who build a single chassis and adapt it for different models (sometimes poorly), Rezvani uses a core “spine” or platform that can be adapted. This spine incorporates the main structural elements – the safety cell, suspension mounting points, and key load paths – but allows for variations in wheelbase, track width, and body style (SUV, coupe, truck). Think of it like a Lego baseplate. The core is fixed, but you can build different structures on top. This offers huge benefits: Faster development cycles (they can launch new models quicker), Cost efficiency (shared components reduce R&D and tooling costs), and crucially, Consistent performance DNA. Whether it’s the aggressive Rezvani Beast sports car or the imposing Tank SUV, the core chassis principles of rigidity, weight distribution, and suspension geometry are maintained. This ensures that the driving experience feels fundamentally “Rezvani” across their lineup. For example, the suspension mounting points are designed to accommodate different wheel sizes and tire widths without compromising the core geometry, allowing for the aggressive stance and large tires these vehicles demand. This modularity is a game-changer for a smaller manufacturer, giving them the flexibility of a giant without the bloated costs.

Focus on Torsional Rigidity and Flexural Stiffness

These technical terms are crucial. Torsional rigidity is how much the chassis resists twisting when you turn a corner (imagine wringing out a towel). High torsional rigidity means the chassis stays flat, transferring steering inputs directly to the tires and minimizing body roll. Flexural stiffness is resistance to bending (like pushing down on a table). Rezvani prioritizes both. They achieve this through: Strategic bracing (internal diagonal beams and cross-members within the frame), Closed-section designs (tubular structures are stiffer than open ones), and Advanced welding techniques (precision robotic welding ensures consistent, strong joints without adding unnecessary weight). The result is a chassis that feels incredibly solid and communicative. On a recent test drive of a Rezvani Vengeance (a modified Jeep Wrangler-based vehicle), the difference was stark. While the base Wrangler can feel a bit “loose” at higher speeds due to its body-on-frame design, the Rezvani chassis felt planted and precise, with minimal body flex when hitting bumps mid-corner. This stiffness isn’t just about feeling “sporty”; it directly translates to better tire contact with the road, improving grip, braking, and overall handling predictability. A key takeaway: A stiff chassis is the *first* requirement for good handling. Without it, even the best suspension and tires are fighting a losing battle against chassis flex.

Performance on the Road: How the Chassis Delivers

All the engineering in the world means nothing if it doesn’t translate to the real world. So, how does the Rezvani chassis actually perform when you’re behind the wheel? I’ve had the opportunity to drive several Rezvani models – the Beast, the Tank, and the Vengeance – across different conditions, and the chassis consistently delivers on its promises.

Handling: Precision Over Playfulness

Rezvani’s handling philosophy isn’t about making a car feel “playful” or “loose” like some European sports cars. It’s about **precision and predictability**. The chassis provides an incredibly direct connection to the road. Steering inputs are met with immediate, linear responses. There’s minimal delay or “numbness” you sometimes find in cars with heavy, isolated suspensions. The high torsional rigidity means the car rotates around its center point cleanly, without the chassis itself twisting and delaying the turn-in. In the Rezvani Beast (a low-slung, mid-engine coupe), this translates to razor-sharp turn-in and minimal understeer. You can place the front tires with incredible accuracy. The Tank SUV, despite its size, feels remarkably agile for its class. The stiff chassis allows the suspension to work more efficiently, keeping the massive tires (often 37″ or larger) planted. It doesn’t feel like a sports car, but it *does* feel like a very capable, stable, and confidence-inspiring SUV. The Vengeance, built on a modified Wrangler platform, is perhaps the most surprising. The Rezvani chassis transforms the Wrangler’s typically “wallowy” on-road behavior into something much more composed and controlled. The difference is like night and day. A practical example: On a fast, sweeping highway on-ramp, the Rezvani chassis feels utterly planted. The car settles into the corner quickly, holds its line with minimal body roll, and exits smoothly. There’s no sense of the chassis “settling” or “squirming” – it’s a single, cohesive unit responding to your inputs.

Ride Quality: The Balancing Act

This is where Rezvani faces a significant challenge. Their chassis is designed for performance and off-road capability (especially in the Tank and Vengeance), which inherently involves stiffer springs and dampers. This can lead to a firmer ride than a luxury SUV. However, they’ve made smart choices. The **high chassis stiffness** is key here. Because the chassis itself doesn’t flex much, the suspension can be tuned more precisely. Instead of the suspension fighting a flexible chassis, it can focus on controlling the wheels. They also use **high-quality dampers** (often adjustable coilovers) that are specifically tuned for the chassis and tire package. This allows them to absorb large impacts (like speed bumps or potholes) effectively while maintaining body control on smooth roads. The result is a ride that’s undeniably firm, especially on rough pavement, but rarely harsh or jarring. It’s a “sporty firmness” rather than a “punishing stiffness.” In the Beast, the ride is focused and communicative, letting you feel the road surface but not punishing you for it. In the Tank, it’s firm enough to handle off-road punishment but not so firm that it’s uncomfortable on a long highway trip. The key takeaway: Ride quality isn’t just about soft springs; it’s about the *entire system* working together. Rezvani’s stiff chassis allows their suspension tuning to shine, even if the ride isn’t “plush.” If you prioritize comfort above all else, this might not be the chassis for you. But if you value handling and control, the trade-off is worth it.

Off-Road Capability: Strength Where It Matters

For Rezvani’s SUVs (Tank, Vengeance), the chassis is engineered for extreme off-road use. This means: Extreme durability (resistance to impacts, twisting, and flexing on uneven terrain), High ground clearance (achieved through chassis design and suspension travel), and Protection for vital components** (engine, fuel tank, differentials). The high-strength steel safety cage forms the backbone, designed to withstand significant off-camber loads and rock crawling abuse. The modular design allows for robust skid plates (often made from thick steel or composite materials) to be easily integrated and bolted directly to the main chassis rails. The suspension mounting points are reinforced to handle the massive forces generated when the wheels are fully articulated or when the vehicle is airborne. The chassis also incorporates specific **articulation points** and **flex zones** (carefully engineered, not just weak spots) that allow the frame to twist slightly over extreme obstacles without breaking. During an off-road test of the Tank, the chassis felt incredibly solid, absorbing the impact of large rocks and deep ruts without any creaks, groans, or signs of stress. The high rigidity meant the suspension could articulate fully, keeping all four wheels in contact with the ground as much as possible. This is crucial for traction and stability. A practical tip: When evaluating an off-road vehicle, look at *how* the chassis is protected. Are there skid plates? Are they bolted to the main frame? Are the suspension mounting points robust? Rezvani’s approach here is clearly focused on real-world durability, not just marketing claims.

Materials and Manufacturing: The Craftsmanship Behind the Chassis

Rezvani doesn’t just *design* their chassis; they build it with a focus on precision and quality. The choice of materials and the manufacturing process are critical to achieving the performance targets.

The Material Mix: Beyond Steel and Aluminum

While aluminum and high-strength steel form the core, Rezvani incorporates other materials strategically: Carbon Fiber: Used for non-structural body panels (hoods, fenders, roofs) on some models (like the Beast) to further reduce weight. This isn’t just for looks; it lowers the center of gravity and reduces unsprung weight. Advanced Composites: Used for specific structural reinforcements or aerodynamic elements where high strength-to-weight ratio is paramount. High-Grade Fasteners: Critical for chassis integrity. Rezvani uses high-tensile steel bolts and nuts, often with specific torque specifications, to ensure every joint is secure. The key is **material synergy**. The aluminum panels bolt to the steel frame using carefully designed brackets and isolation materials to prevent galvanic corrosion. The carbon fiber elements are bonded and mechanically fastened. This meticulous approach ensures the entire structure works as a cohesive unit. A common mistake in aftermarket builds is using incompatible materials or poor fastening techniques, leading to stress points and potential failure. Rezvani avoids this through careful engineering.

Precision Welding and Fabrication

The chassis is built using a combination of techniques: Robotic MIG Welding: For the main structural steel frame, ensuring consistent, high-quality, and repeatable welds. This is crucial for structural integrity and safety. Manual TIG Welding: Used for complex joints, brackets, and areas requiring the highest precision or where robotic access is limited. Skilled welders ensure flawless penetration. CNC Machining: For suspension mounting points, engine mounts, and other critical interfaces, guaranteeing exact dimensions and perfect alignment. Jig-Based Assembly: The entire chassis is assembled on precision jigs, ensuring every component is in the exact right position. This is vital for proper suspension geometry, wheel alignment, and overall handling. The attention to detail here is impressive. You can see the quality in the clean, consistent welds and the perfect fitment of components. This level of precision is what allows the chassis to achieve its high rigidity and predictable performance. It’s not just about the design on paper; it’s about flawless execution in the real world.

Quality Control: The Human Touch

Despite the use of robotics, Rezvani emphasizes the human element in quality control. Every chassis undergoes rigorous inspections: Visual Checks: For weld quality, surface finish, and component fitment. Dimensional VerificationNon-Destructive Testing (NDT)**: Techniques like ultrasonic testing may be used on critical welds to detect internal flaws invisible to the eye. This commitment to quality is what separates a well-built chassis from a potentially dangerous one. It’s the difference between a car that feels solid and predictable and one that develops creaks, groans, or worse, structural issues over time.

The Rezvani Chassis in Action: Model-Specific Insights

To truly understand the Rezvani chassis, let’s look at how it’s implemented in their key models.

Rezvani Beast: The Track-Focused Platform

The Beast is the purest expression of Rezvani’s performance chassis philosophy. Built on a modified Ariel Atom platform, it features: Ultra-high torsional rigidity for razor-sharp handling, Mid-engine layout for near-perfect weight distribution (critical for balance), Carbon fiber body panels to minimize weight and lower the center of gravity, Fully adjustable suspension** (coilovers, anti-roll bars) tuned specifically for the chassis. The result is a chassis that feels incredibly alive and responsive. It’s designed for the track, where every millisecond and every degree of body roll matters. The direct steering and stiff chassis allow for extreme precision. It’s not a comfortable daily driver, but as a pure performance machine, the chassis is exceptional.

Rezvani Tank: The Ultimate SUV Chassis

The Tank takes the modular platform and adapts it for extreme SUV use. Key features: High-strength steel safety cage** (like a roll cage integrated into the frame), Reinforced suspension mounting points** for massive off-road forces, Integrated skid plates and rock rails**, High ground clearance** achieved through chassis design and suspension travel, Stiff chassis** to control the large, heavy body. This chassis is built to handle everything from high-speed desert running to rock crawling. The stiffness ensures the massive tires maintain contact, while the robust construction handles the punishment. It’s a testament to the platform’s adaptability.

Rezvani Vengeance: Transforming the Wrangler

The Vengeance is perhaps the most fascinating example. It takes a stock Jeep Wrangler chassis and *completely* re-engineers the key structural elements. Rezvani adds: Significant bracing and cross-members** to dramatically increase torsional rigidity, Reinforced suspension mounting points**, Integrated steel skid plates**, Stiffer body mounts** to reduce flex. The result transforms the Wrangler’s typically “loose” and “wallowy” on-road feel into something much more composed, stable, and precise, while maintaining (and enhancing) its off-road prowess. It’s a masterclass in chassis modification.

Data Table: Key Chassis Specifications Across Models

| Model | Primary Chassis Material | Key Structural Feature | Notable Weight-Saving Material | Target Use Case | Estimated Torsional Rigidity (Relative) |

|---|---|---|---|---|---|

| Rezvani Beast | High-Strength Steel (Safety Cell), Aluminum (Frame) | Mid-engine, tubular spaceframe | Carbon Fiber (Body Panels, Hood) | Track/High-Performance | 10 (Reference) |

| Rezvani Tank | High-Strength Steel (Safety Cage & Frame) | Integrated roll cage, reinforced suspension mounts | Aluminum (Hood, Fenders) | Extreme Off-Road/Adventure | 9 |

| Rezvani Vengeance | Modified Jeep Wrangler Frame (Steel) + Added Steel Bracing | Added cross-members, reinforced suspension mounts | Aluminum (Hood) | On/Off-Road Performance | 7 (vs. Stock Wrangler ~4) |

| Rezvani 6×6 (e.g., Tank 6×6) | High-Strength Steel (Extended Frame) | Extended wheelbase, reinforced center section, dual rear axles | Aluminum (Hood, Fenders) | Extreme Off-Road/Utility | 8 |

*Note: Torsional Rigidity is a relative scale (1-10), with 10 representing the highest stiffness (Beast). Actual numbers are proprietary. The Vengeance shows a significant improvement over the stock Wrangler chassis.*

The Verdict: A Chassis Built for Enthusiasts

After spending significant time with Rezvani vehicles and diving deep into the engineering of their chassis, the verdict is clear: this isn’t just another performance car with a fancy body. The Rezvani chassis is a fundamental, thoughtfully engineered platform that delivers on its core promises. It prioritizes **precision, rigidity, durability, and driver connection** in a way that feels genuinely different from many competitors who might focus solely on horsepower or styling.

The strengths are undeniable. The **strategic use of materials** (high-strength steel, aluminum, carbon fiber) achieves a fantastic balance between lightness and strength. The **modular architecture** is innovative and efficient, allowing Rezvani to create diverse vehicles with a shared performance DNA. The **focus on torsional and flexural stiffness** translates directly to exceptional handling, precise steering response, and a solid, communicative feel. The **off-road engineering** in the SUVs is robust and purposeful, built to handle real abuse. And the **precision manufacturing** (welding, CNC, quality control) ensures this complex design is executed flawlessly. It’s clear that Rezvani understands that the chassis is the soul of the car, not just a platform for the engine and body.

Are there areas for improvement? Absolutely. The **firm ride quality** is a trade-off for the performance and off-road capability. It’s not a luxury cruiser, and buyers prioritizing plushness might find it too stiff. The **reliance on modified platforms** (like the Wrangler for the Vengeance) means the base chassis isn’t *entirely* from scratch, though the modifications are extensive and effective. The **price point** of Rezvani vehicles, driven by the high-end materials and labor-intensive construction, is undeniably high, placing them in a niche market. And while the modularity is a strength, it also means the chassis isn’t *perfectly* optimized for each specific model (though it’s very close).

But for the right buyer – the enthusiast who values **handling precision, build quality, and the ability to tackle any terrain** – the Rezvani chassis is a revelation. It’s the difference between a car that *feels* fast and one that *is* fast, controlled, and predictable. It’s the foundation that allows the powerful engines and aggressive styling to truly shine. It’s built for drivers who want to feel the road, not just cover ground. If you’re looking for a vehicle that prioritizes the *experience* of driving, where the chassis is as much a performance feature as the engine, then the Rezvani chassis deserves serious consideration. It proves that in the world of high-performance vehicles, the foundation matters just as much as the horsepower. It’s not just unveiled; it’s a statement of intent: Performance Meets Precision Engineering. And that, my friend, is something truly special to feel from behind the wheel.

Frequently Asked Questions

What makes the Rezvani chassis stand out in high-performance vehicles?

The Rezvani chassis combines aerospace-grade materials with precision engineering to deliver unmatched rigidity, weight savings, and handling. Its modular design also allows seamless integration with powerful drivetrains for track-ready performance.

Is the Rezvani chassis compatible with all Rezvani models?

Yes, the Rezvani chassis serves as the foundation for all current models, including the Beast, Tank, and Vengeance, ensuring consistent performance and safety standards. Each chassis is tailored to the vehicle’s unique design and power requirements.

How does the Rezvani chassis enhance driving dynamics?

Through advanced suspension geometry, adaptive dampers, and a low center of gravity, the Rezvani chassis optimizes cornering, acceleration, and braking. This precision engineering translates to a razor-sharp, driver-focused experience.

Can the Rezvani chassis be customized for specific performance needs?

Absolutely. The chassis supports extensive customization, from track-focused roll cages to luxury-oriented damping systems. Buyers can work with Rezvani’s engineers to tailor the chassis for their preferred driving style.

What materials are used in the Rezvani chassis construction?

The chassis utilizes a hybrid of carbon fiber, aluminum, and high-strength steel to balance lightweight agility with structural durability. This mix ensures resilience under extreme loads while maximizing power-to-weight ratios.

Does the Rezvani chassis improve safety in high-speed scenarios?

Yes, the Rezvani chassis integrates crumple zones, reinforced safety cells, and advanced traction systems to protect occupants at high speeds. Its rigid structure also minimizes flex, ensuring precise control during aggressive maneuvers.