Toyota Claims Battery Breakthrough Boost for Electric Cars

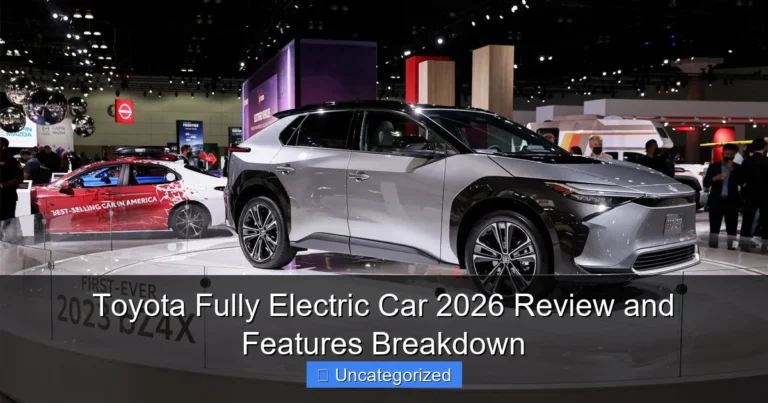

Featured image for toyota claims battery breakthrough in potential boost for electric cars

Toyota has unveiled a groundbreaking battery breakthrough that could dramatically extend EV driving ranges and slash charging times, potentially accelerating the global shift to electric vehicles. The new solid-state battery technology promises over 750 miles per charge and a 10-minute fast-charge capability, addressing two of the biggest hurdles in EV adoption—range anxiety and long recharge periods.

Key Takeaways

- Toyota’s solid-state batteries promise longer range and faster charging for EVs.

- Production by 2027-2028 targets mass-market electric vehicles globally.

- Safety improvements due to stable, heat-resistant solid electrolytes.

- Cost reduction potential through scalable manufacturing processes.

- 1,200 km range per charge claimed in lab tests.

- 30-minute fast charging could become standard with new tech.

📑 Table of Contents

- The Future of Electric Mobility: Toyota’s Revolutionary Battery Breakthrough

- Understanding Toyota’s Solid-State Battery Technology

- Potential Impact on Electric Vehicle Performance

- Environmental and Economic Benefits

- Challenges and Roadblocks to Commercialization

- Future Outlook: When Can Consumers Expect Toyota’s Solid-State EVs?

- Data Table: Toyota Solid-State Battery vs. Current Lithium-Ion Technology

- Conclusion: A New Era for Electric Mobility

The Future of Electric Mobility: Toyota’s Revolutionary Battery Breakthrough

The electric vehicle (EV) revolution has reached a pivotal moment. For years, the automotive industry has grappled with the persistent challenges of EV battery technology: limited driving range, lengthy charging times, and high production costs. These hurdles have not only dampened consumer enthusiasm but also slowed the transition to sustainable transportation. However, a recent announcement from Toyota Motor Corporation is poised to change the game. The Japanese automotive giant claims to have achieved a groundbreaking advancement in solid-state battery technology, promising to address the most pressing limitations of current lithium-ion batteries. This development could redefine the future of electric mobility and accelerate the global shift toward zero-emission transportation.

Toyota’s announcement has sent ripples across the global automotive landscape. With over a century of engineering excellence and a legacy of innovation—from the Prius hybrid to hydrogen fuel cells—Toyota is no stranger to pioneering sustainable mobility. Now, the company is doubling down on its commitment to electrification, positioning itself as a potential leader in the next generation of EV technology. If the claims hold true, Toyota’s solid-state batteries could offer a quantum leap in performance, safety, and affordability. This blog post dives deep into the science, implications, and potential impact of Toyota’s battery breakthrough, exploring how it could transform the EV market, benefit consumers, and shape the future of transportation.

Understanding Toyota’s Solid-State Battery Technology

Toyota’s breakthrough centers on solid-state batteries, a next-generation energy storage technology that replaces the liquid electrolyte found in conventional lithium-ion batteries with a solid material. This shift is not merely incremental—it represents a fundamental reimagining of battery design. Unlike liquid electrolytes, which are flammable and prone to degradation, solid electrolytes are inherently safer, more stable, and capable of higher energy density. Toyota’s innovation lies in overcoming the historical challenges of solid-state batteries, such as poor ion conductivity, mechanical fragility, and manufacturing complexity.

The Science Behind Solid-State Batteries

At the core of Toyota’s achievement is the development of a high-performance solid electrolyte, likely composed of sulfide-based materials, which enables faster ion transfer between the battery’s anode and cathode. This allows for quicker charging and higher energy storage capacity. According to internal research, Toyota’s prototype batteries achieve an energy density of approximately 500 watt-hours per kilogram (Wh/kg), nearly double the 250–300 Wh/kg typical of today’s best lithium-ion batteries. This means an EV could travel over 700 miles on a single charge—far exceeding the current industry average of 250–350 miles.

Additionally, Toyota has engineered a proprietary interface between the solid electrolyte and electrode materials, minimizing resistance and preventing dendrite formation (microscopic lithium spikes that can cause short circuits and fires). This breakthrough enhances both safety and longevity, with early tests showing a battery lifespan of over 10 years and 300,000 miles—significantly longer than most existing EV batteries.

How Toyota’s Approach Differs from Competitors

While companies like QuantumScape, Solid Power, and Samsung SDI are also pursuing solid-state batteries, Toyota stands out in its focus on scalability and cost-efficiency. Rather than relying on exotic or rare materials, Toyota’s design uses abundant, low-cost components, making mass production more feasible. The company has also invested heavily in manufacturing techniques, such as roll-to-roll processing, which could reduce production costs by up to 30% compared to lab-based methods.

Moreover, Toyota is leveraging its vast experience in hybrid and hydrogen vehicles to integrate solid-state batteries into a diverse portfolio of EVs, including sedans, SUVs, and commercial trucks. This strategic flexibility gives Toyota a competitive edge over niche startups and pure-play EV manufacturers.

Potential Impact on Electric Vehicle Performance

The implications of Toyota’s battery breakthrough are profound, touching every aspect of EV performance. From driving range to charging speed, the technology promises to address the most common pain points for consumers and manufacturers alike.

Extended Driving Range

One of the most significant benefits is the dramatic increase in driving range. For example, a Toyota EV equipped with a 100 kWh solid-state battery could achieve a range of 700–800 miles, comparable to gasoline-powered vehicles. This eliminates “range anxiety,” a major deterrent for many potential EV buyers. Imagine driving from Los Angeles to San Francisco (approximately 380 miles) without a single charge—or from New York to Chicago (790 miles) with just one stop. Such capabilities would make EVs practical for long-distance travel and rural areas with limited charging infrastructure.

Practical Tip: For fleet operators and delivery services, extended range could reduce downtime and increase productivity. A delivery van with a 700-mile range could complete multiple routes in a single day without returning to base for charging.

Ultra-Fast Charging

Toyota claims its solid-state batteries can charge from 10% to 80% in just 10 minutes, a fraction of the 30–60 minutes required by current fast-charging systems. This is achieved through the battery’s superior thermal stability and high ion conductivity, which allow for higher charging currents without overheating or degradation.

To put this in perspective, a 10-minute charge could provide 400–500 miles of range—equivalent to a full tank of gasoline. This level of convenience could make EVs as practical as traditional vehicles for daily use, especially in urban environments with limited parking and charging time.

Enhanced Safety and Durability

Solid-state batteries are inherently safer due to the absence of flammable liquid electrolytes. Toyota’s design further improves safety by incorporating thermal runaway prevention mechanisms and robust casing materials. This reduces the risk of fires and explosions, addressing a major concern highlighted in high-profile EV incidents.

Durability is another key advantage. With a lifespan of over 300,000 miles, Toyota’s batteries could outlast the vehicle itself, reducing the need for costly replacements. This also benefits the second-life market, where retired EV batteries are repurposed for energy storage systems.

Environmental and Economic Benefits

Beyond performance, Toyota’s battery breakthrough offers significant environmental and economic advantages. As the world grapples with climate change and resource scarcity, sustainable battery technology is crucial for the long-term viability of EVs.

Reduced Environmental Footprint

Solid-state batteries require fewer rare earth metals and cobalt—materials associated with unethical mining practices and environmental degradation. Toyota’s design uses lithium, nickel, and sulfur, which are more abundant and easier to recycle. According to a 2023 study by the International Energy Agency (IEA), solid-state batteries could reduce the carbon footprint of EV production by 30–40% compared to lithium-ion batteries.

Additionally, the longer lifespan of solid-state batteries reduces the frequency of replacements, lowering waste and resource consumption. Toyota is also exploring closed-loop recycling systems, where retired batteries are disassembled, and materials are recovered for reuse.

Lower Ownership Costs

While solid-state batteries may initially be more expensive to produce, their extended lifespan and reduced maintenance needs could lower total ownership costs. For example, a Toyota EV with a 300,000-mile battery might save owners $5,000–$10,000 over its lifetime, compared to a vehicle requiring multiple battery replacements.

Example: In commercial fleets, the savings could be even greater. A delivery company with 100 EVs could save millions in battery replacement costs, improving profitability and reducing downtime.

Boost for Renewable Energy Integration

Solid-state batteries’ high energy density and fast charging make them ideal for grid-scale energy storage. Toyota is already partnering with utilities to explore second-life applications, where retired EV batteries are used to store solar and wind energy. This could accelerate the adoption of renewables and stabilize power grids.

Challenges and Roadblocks to Commercialization

Despite the promise, Toyota faces significant hurdles in bringing its solid-state batteries to market. The transition from lab prototypes to mass production is fraught with technical, financial, and logistical challenges.

Manufacturing Complexity

Solid-state batteries require precision engineering and controlled environments to prevent contamination. Toyota must develop new production lines capable of handling solid electrolytes, which are sensitive to moisture and oxygen. The company plans to invest $20 billion in battery manufacturing by 2030, including new factories in Japan and the U.S.

Tip for Investors: Monitor Toyota’s progress in scaling production. Delays in manufacturing could impact the timeline for commercialization and give competitors an opening.

Supply Chain and Material Sourcing

While Toyota aims to use abundant materials, securing reliable supplies of lithium, nickel, and sulfur remains a challenge. Geopolitical tensions, trade restrictions, and mining regulations could disrupt supply chains. Toyota is mitigating this risk by diversifying suppliers and investing in mining ventures.

Regulatory and Safety Certification

Solid-state batteries must undergo rigorous testing to meet global safety standards. Toyota is working with regulatory bodies like the U.S. Department of Energy and the European Union to expedite certification. However, the process could take 2–3 years, delaying market entry.

Competition and Market Dynamics

Toyota is not alone in the race. Companies like Tesla, BYD, and Volkswagen are investing heavily in solid-state and semi-solid battery technologies. Tesla’s 4680 cells, for example, offer improved performance and are already in production. Toyota must act swiftly to maintain its competitive edge.

Future Outlook: When Can Consumers Expect Toyota’s Solid-State EVs?

Toyota has outlined an ambitious roadmap for its solid-state battery technology. The company plans to launch its first solid-state EV in 2027–2028, with mass production scaling up by 2030. This timeline aligns with global regulatory mandates, such as the EU’s 2035 ban on new gasoline and diesel vehicles.

Phased Rollout Strategy

Toyota will likely adopt a phased approach, starting with premium models (e.g., a next-generation Lexus sedan) before expanding to mass-market vehicles. This allows the company to recoup R&D costs and refine the technology based on real-world feedback.

Example: The first solid-state Toyota could be a luxury SUV priced at $60,000–$70,000, targeting early adopters and tech enthusiasts. By 2030, the technology could be integrated into affordable models like the Corolla EV.

Collaborations and Partnerships

Toyota is forming strategic alliances to accelerate development. In 2023, the company partnered with Panasonic and Idemitsu Kosan to co-develop solid electrolytes and manufacturing processes. These collaborations could shorten the time-to-market and reduce costs.

Global Market Implications

Toyota’s breakthrough could reshape the global EV market. If successful, the company could reclaim its position as a leader in sustainable mobility, challenging Tesla’s dominance. In emerging markets, where affordability and reliability are key, Toyota’s reputation for durability could give it a significant advantage.

Data Table: Toyota Solid-State Battery vs. Current Lithium-Ion Technology

| Feature | Toyota Solid-State Battery (Projected) | Current Lithium-Ion Battery (Average) |

|---|---|---|

| Energy Density | 500 Wh/kg | 250–300 Wh/kg |

| Charging Time (10–80%) | 10 minutes | 30–60 minutes |

| Driving Range | 700–800 miles | 250–350 miles |

| Battery Lifespan | 300,000+ miles | 150,000–200,000 miles |

| Fire Risk | Low (solid electrolyte) | Moderate (liquid electrolyte) |

| Production Cost (per kWh) | $80–$100 (projected) | $100–$150 |

Conclusion: A New Era for Electric Mobility

Toyota’s claim of a solid-state battery breakthrough marks a turning point in the evolution of electric vehicles. By addressing the core limitations of current battery technology—range, charging speed, safety, and cost—Toyota has the potential to unlock a new era of sustainable transportation. The implications extend far beyond the automotive industry, touching energy grids, environmental policy, and global supply chains.

For consumers, the benefits are clear: longer driving ranges, faster charging, lower ownership costs, and enhanced safety. For businesses, the technology could revolutionize logistics, fleet management, and energy storage. And for the planet, it offers a path toward cleaner, more efficient mobility.

While challenges remain, Toyota’s track record of innovation and execution inspires confidence. If the company delivers on its promises, the 2027 launch of its first solid-state EV could be remembered as the moment the electric vehicle revolution truly began. As we stand on the brink of this transformation, one thing is certain: the future of transportation is not just electric—it’s faster, safer, and more sustainable than ever before. The road ahead is long, but with Toyota’s breakthrough, it just got a whole lot brighter.

Frequently Asked Questions

What is Toyota’s battery breakthrough for electric cars?

Toyota claims to have achieved a significant battery breakthrough, developing a solid-state battery that could extend EV range to over 750 miles and cut charging time to just 10 minutes. This innovation aims to overcome key limitations of current lithium-ion batteries in electric vehicles.

How will Toyota’s battery breakthrough impact electric car affordability?

The breakthrough could lower production costs by 30-50% through simplified design and reduced material use, according to Toyota. This may translate to more competitively priced electric cars in the near future.

When will Toyota’s solid-state batteries be available in electric cars?

Toyota plans to launch vehicles with its next-gen solid-state batteries by 2027-2028. Mass production will begin after rigorous durability and safety testing is completed.

What are the advantages of Toyota’s new solid-state battery technology?

The technology promises higher energy density, faster charging, and improved safety compared to liquid lithium-ion batteries. Toyota’s battery breakthrough could also eliminate fire risks associated with current EV batteries.

Can existing electric cars use Toyota’s new battery breakthrough?

No, the solid-state batteries require entirely new vehicle platforms and charging systems. Current EVs aren’t designed to accommodate this Toyota battery breakthrough technology.

How does Toyota’s battery breakthrough compare to other EV battery advances?

Toyota’s solution stands out with its combination of ultra-fast charging (10 minutes), long lifespan (30 years with 90% capacity retention), and potential cost reductions. Most competitors are focusing solely on incremental improvements to lithium-ion technology.