Master Plan: Creating the Perfect Strategy for Working with HEVs and EVs

If you are an avid fan of electric vehicles, you know that they have slowly but surely carved a niche in the market. With an increasing demand for eco-friendly transportation, hybrid electric vehicles (HEVs) and electric vehicles (EVs) are becoming a more common sight on the roads. EVs and HEVs are not only beneficial to the environment, but they also provide a comfortable and cost-effective mode of transport.

However, it is important to remember that they require proper handling and maintenance – especially when it comes to the safety and effectiveness of operations. In this day and age, where innovation is at the forefront of technological advancements, it is essential to keep up-to-date with the safety measures necessary to keep you and your vehicle safe, particularly when working with HEVs and EVs. Whether you are a mechanic, automobile technician or a hobbyist who loves to tinker with electric cars, it is vital to understand the structure and components of the vehicle and the possible safety hazards associated with working on them.

The safety of HEVs and EVs is critical. One wrong move can lead to serious injury or even death. With the rise in electric car usage, safety measures, regulations, and protocols must be put in place to ensure the safety of users, passengers, and technicians working on the vehicles’ components.

Hence, knowing the recommended safety practices for working on electric vehicles, including equipment safety, proper handling of HEV and EV batteries, and charging procedures, is crucial. Lastly, as more and more manufacturers begin to release their electric vehicle models, it is essential to be an expert in the field. You can stay up-to-date with the latest advancements in the sector, and continue to learn about the safety measures and components involved.

Overall, adopting safe and effective OH&S practices when working on HEVs and EVs can help you become a better technician or enthusiast while also ensuring your and others’ safety.

Proper Design Plan

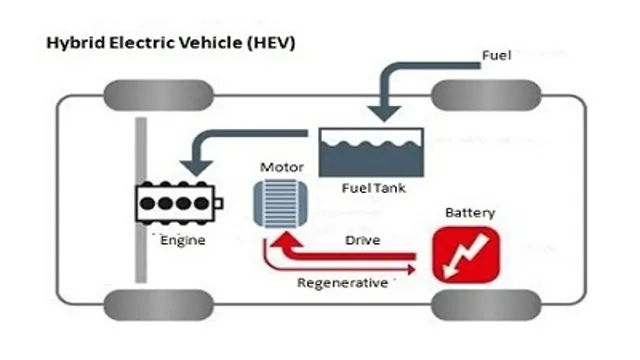

When working with HEVs (hybrid electric vehicles) and EVs (electric vehicles), it is crucial to create a proper design plan. With traditional fuel-powered vehicles, the focus was primarily on the engine and how it could be made more efficient. However, with HEVs and EVs, the focus has shifted to the electric powertrain.

A well-thought-out design plan should include considerations such as the battery pack size, layout, and placement, as well as the motor configuration. Additionally, aspects such as regenerative braking and thermal management systems must also be taken into account. By prioritizing the design of the electric powertrain and other critical features, we can ensure that the vehicle operates smoothly and efficiently.

Ultimately, having a comprehensive plan in place from the start will save time and money while improving the performance, range, and reliability of these eco-friendly vehicles. So remember, when working with HEVs and EVs, you must create a proper design plan to ensure a successful outcome.

Planning for Electrical and Mechanical Systems

When it comes to planning for electrical and mechanical systems, it’s crucial to have a proper design plan in place. This allows for the efficient use of resources, avoids costly mistakes, and ensures that everything runs smoothly once the systems are in place. Start by considering the specific needs of the building or project at hand, including the size and layout, as well as any special requirements or requests from stakeholders.

From there, work with a team of qualified professionals to create a comprehensive plan that takes into account everything from power distribution and lighting to HVAC and plumbing. By investing the time and effort upfront to create a solid design plan, you can rest assured that your electrical and mechanical systems will meet your needs while also being safe, reliable, and cost-effective in the long run. So don’t delay – start planning today!

Calculating Battery Size and Capacity

When it comes to designing a battery system for your application, it’s important to have a proper design plan in place to determine the size and capacity of the battery required. This starts with understanding the power requirements of your system and calculating the amount of energy needed to power it. Factors such as operating time, load current, and peak current should all be taken into consideration.

Additionally, the type of battery chemistry used will also play a role in determining the capacity needed. For example, lithium-ion batteries have a higher energy density compared to lead-acid batteries, which means you can get more energy in a smaller package. By using a proper design plan, you can ensure that your battery system meets your power requirements while also being efficient and cost-effective.

Smart Control System

When working with HEVs and EVs, it’s essential to create a smart control system that maximizes energy efficiency and improves the overall driving experience. A well-designed control system can monitor and regulate everything from battery usage to acceleration and braking patterns to ensure optimal performance and longevity. With the advancements in technology, modern control systems can even leverage machine learning algorithms to adapt and improve based on the driver’s behavior and environmental conditions.

By collecting and analyzing real-time data, these systems can make informed decisions to improve energy efficiency and reduce emissions while still providing a smooth and enjoyable ride. In short, a smart control system is essential for both drivers and the environment, making hybrid and electric vehicles a viable and sustainable solution for the future of transportation.

Building a Reliable Battery Management System

A reliable battery management system is essential for ensuring your batteries operate at peak efficiency and last longer. A smart control system can help you achieve this goal. This system uses artificial intelligence and machine learning to monitor the conditions of your batteries and adjust the voltage and current as needed.

This technology can also detect potential issues before they become serious problems and alert you so you can take action. It’s like having a personal assistant for your batteries! By utilizing a smart control system, you can extend the life of your batteries and save money on replacements and maintenance costs. It’s a small investment that can have a big impact on your bottom line.

Integrating Control Modules for Optimal Performance

Integrating control modules can help optimize the performance of a smart control system. This type of system utilizes various sensors and devices to monitor and control different aspects of a building, such as lighting, temperature, and security. By integrating these control modules, the system can operate more efficiently and effectively.

For example, if the temperature sensor detects that a room is too warm, the system can automatically adjust the HVAC system to bring the temperature down. Similarly, if the security system detects an intrusion, it can trigger the lighting system to turn on and alert the homeowner. By combining the various control modules, the smart control system can provide a seamless experience for the user and improved energy efficiency.

By doing so, this will help reduce energy bills and enhance the overall performance of the system.Keyword: Smart Control System.

Implementing Safety Measures for High Voltage Systems

When it comes to implementing safety measures for high voltage systems, a smart control system can be a game-changer. With the use of advanced technologies such as artificial intelligence and machine learning, a smart control system can detect any potential hazards and take necessary actions in real-time to prevent accidents. This system can also provide remote access, allowing operators to monitor and control the high voltage systems from a safe distance.

When it comes to maintaining high voltage systems, a smart control system can reduce the need for human intervention, reducing the risks associated with human errors. So, if you’re looking to enhance the safety of your high voltage systems, consider investing in a smart control system.

Effective Testing and Maintenance

When working with HEVs and EVs, you must create a thorough testing and maintenance plan to ensure their optimal functionality. These vehicles have complex systems that require specialized knowledge and equipment for testing and maintenance. Regular maintenance is necessary to prevent potential malfunctions that could compromise the safety of the vehicle, and that of the driver and passengers.

Additionally, thorough testing is required before releasing the vehicle to customers to ensure that everything is working as intended. Failure to do so not only risks the safety of the driver and passengers but could also result in costly repair and replacement expenses. By investing in a proper testing and maintenance plan, you can ensure the longevity of your HEV or EV and keep it running smoothly for years to come.

So, remember to create a plan and stick to it, and don’t skimp when it comes to testing and maintenance.

Performing System Checks for Optimal Functionality

Performing system checks on your technology is essential for optimal functionality. By effectively testing and maintaining your systems, you can detect any issues before they become major problems that can cause costly downtime, loss of data, and potentially harm your operations. An efficient testing and maintenance system entails a standardized process whereby every device in your network is assessed and tested regularly for errors or potential failures.

This ensures that your systems are always up-to-date, secure, and optimized for peak performance. Think of it like getting regular checkups at the doctor’s office to maintain your health and prevent serious illness. By performing regular system checks, you can avoid unexpected crashes or other issues that can disrupt your business, while also prolonging the life of your technology investments.

Don’t wait until a problem arises, be proactive and implement an effective testing and maintenance system for your technology today.

Conducting Regular Maintenance for Long-Term Performance

Effective testing and maintenance are crucial for the long-term performance of any system or machine. Conducting routine maintenance tasks, such as inspections, cleanings, and lubrications, helps prevent unexpected breakdowns and prolongs the lifespan of the equipment. By establishing a regular maintenance schedule, you can identify potential issues early on, which can save you time and money in the long run.

Effective testing, on the other hand, involves more than just checking that everything is working properly. It requires careful observation and analysis of the system’s performance to identify any inefficiencies or deviations from the expected results. By conducting regular testing and analysis, you can make any necessary adjustments to optimize the system’s performance and improve its overall efficiency.

It’s essential to note that maintenance and testing go hand in hand. The results of testing can inform maintenance tasks by highlighting problem areas that need attention. Similarly, maintenance ensures that the system is in top condition for effective testing.

Both are essential for ensuring long-term performance and avoiding unexpected downtime. In conclusion, conducting regular maintenance and testing is integral to maintaining the long-term performance of any system or machine. By taking a proactive approach, you can identify potential issues early on and make necessary adjustments to optimize performance and avoid unexpected downtime.

With a well-planned maintenance and testing schedule, you can ensure that your equipment continues to operate at peak efficiency for years to come.

Conclusion: Creating a Successful HEV and EV System

When working with HEVs and EVs, you must create a symbiotic relationship between your brain and the battery. Just like a koala and eucalyptus leaves, the two entities depend on each other to thrive. So go ahead, embrace your inner battery whisperer and let the electrifying ride begin!

FAQs

What is the difference between HEV and EV?

HEVs (Hybrid Electric Vehicles) combine an internal combustion engine with an electric motor, while EVs (Electric Vehicles) use only an electric motor powered by rechargeable batteries.

What are the benefits of driving an HEV or EV?

HEVs and EVs have lower emissions, reduced fuel costs, and require less maintenance than traditional vehicles. They also tend to offer a smoother and quieter driving experience.

How do you charge an EV?

EVs can be charged using a standard household outlet, a dedicated EV charger, or at public charging stations.

How far can an EV travel on a single charge?

The range of an EV depends on the model, but most current models can travel between 100-250 miles on a single charge. Range can also be affected by driving habits, weather, and terrain.

Can an EV be used in extremely cold or hot temperatures?

Yes, but extreme temperatures can affect the range of an EV. Some models come with specialized battery heating and cooling systems to help combat these issues.