Where Is Rezvani Tank Made Unveiling the Manufacturing Hub

Featured image for where is rezvani tank made

Image source: blog.luxurycare.org

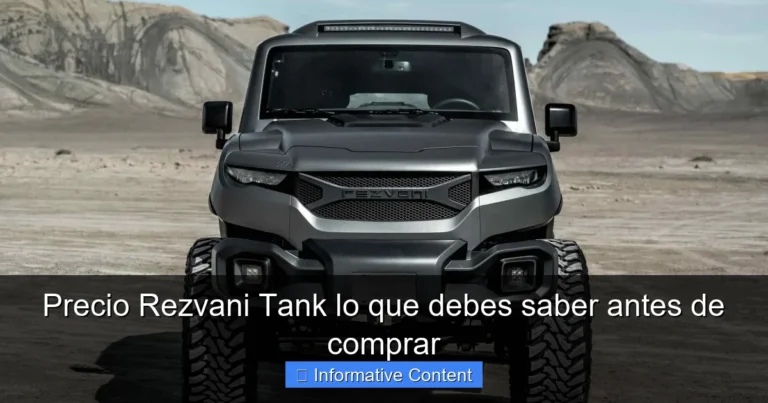

The Rezvani Tank is proudly manufactured in the USA, specifically in Orange County, California, where cutting-edge design meets high-performance engineering. Every unit is hand-built in a state-of-the-art facility, ensuring precision, durability, and the aggressive luxury that defines the Rezvani brand. This American-made powerhouse blends military-inspired aesthetics with supercar-level performance, all crafted in its dedicated Southern California hub.

Key Takeaways

- Rezvani Tank is made in California, ensuring high-quality craftsmanship and local innovation.

- Production occurs in a specialized facility, tailored for luxury and armored vehicles.

- Each unit undergoes rigorous testing, guaranteeing durability and performance standards.

- Skilled technicians hand-assemble every Tank, blending precision with custom design.

- Materials are sourced globally, combining strength and luxury for elite buyers.

- Local manufacturing supports rapid prototyping, enabling quick customization and upgrades.

📑 Table of Contents

- The Story Behind the Rezvani Tank: More Than Just a Car

- The Origins of the Rezvani Tank: From Idea to Reality

- Where Is Rezvani Tank Made? The Manufacturing Hub Explained

- The Role of Technology and Innovation in Manufacturing

- Challenges and Limitations of the Manufacturing Model

- Comparing Rezvani’s Process to Traditional Automakers

- The Future of Rezvani: Where Will the Next Tank Be Made?

- Conclusion: The Soul of the Tank Is in Its Craft

The Story Behind the Rezvani Tank: More Than Just a Car

Picture this: You’re driving down a quiet suburban street, and suddenly, a vehicle that looks like it rolled straight out of a military base or a sci-fi movie turns the corner. It’s angular, imposing, and covered in armor. That’s the Rezvani Tank. It’s not just a car—it’s a statement. Built for those who want to feel invincible, the Tank has captured the attention of car enthusiasts, security experts, and even Hollywood. But as you watch it disappear down the road, one question lingers: Where is Rezvani Tank made?

The answer isn’t as simple as pointing to a single factory in Detroit or Stuttgart. The Rezvani Tank is the result of a fascinating blend of American ingenuity, global sourcing, and cutting-edge engineering. In this deep dive, we’ll peel back the layers of its creation, explore its manufacturing roots, and uncover what makes this armored SUV so unique. Whether you’re a car lover, a tech geek, or someone who just wants to know where their dream machine comes from, this is the story of the Tank’s birthplace—and the people behind it.

The Origins of the Rezvani Tank: From Idea to Reality

How a Vision Became a Beast on Wheels

The Rezvani Tank didn’t just appear overnight. It was born from the mind of Ferris Rezvani, an Iranian-American entrepreneur and car designer with a passion for high-performance vehicles. After working with luxury and exotic car brands, Ferris wanted to create something different—a vehicle that combined the ruggedness of a military truck with the comfort of a luxury SUV. The goal? To build a car that could survive anything, from a zombie apocalypse to a high-speed chase.

Visual guide about where is rezvani tank made

Image source: laguiadelvaron.com

Launched in 2017, the Tank was Rezvani Automotive’s first major model. It wasn’t just about looks. Ferris wanted functionality: bulletproof glass, run-flat tires, thermal night vision, and even an optional “EMP protection” system. But none of that would matter if the car couldn’t be built. So, the next step was figuring out where and how to make it. That’s where the real journey began.

Why the U.S. Was the Starting Point

Rezvani Automotive is headquartered in Irvine, California, a hub for tech startups and automotive innovation. Irvine is home to major players in the EV and performance car space, and its proximity to engineering talent, design schools, and manufacturing partners made it the ideal launchpad. The company didn’t just pick a random city—it chose a place where creativity meets capability.

But here’s the thing: Rezvani isn’t a traditional automaker. It doesn’t have a massive assembly line like Ford or Toyota. Instead, it operates more like a high-end boutique builder. Think of it like a custom tailor for cars. They design the blueprint, source the materials, and oversee the build—but they rely on a network of trusted partners to bring the Tank to life. This hybrid model is key to understanding where the Rezvani Tank is made.

Where Is Rezvani Tank Made? The Manufacturing Hub Explained

The Core Facility: Irvine, California

The heart of the Rezvani Tank’s creation is its Irvine headquarters. This isn’t just an office—it’s a fully functional design and assembly center. Here, engineers, designers, and technicians work on every stage of the Tank’s development, from 3D modeling to final quality checks. The facility includes:

- A design studio where the Tank’s aggressive lines and futuristic features are sketched and refined.

- A workshop for prototyping and small-batch assembly.

- A quality control lab for testing armor, electronics, and performance systems.

But here’s the catch: The Tank isn’t built entirely in Irvine. Because Rezvani uses a modular manufacturing approach, some components are sourced and assembled elsewhere. For example, the base vehicle—usually a Jeep Wrangler—is delivered to Irvine partially built. The Rezvani team then strips it down and rebuilds it with their custom body, armor, and tech.

Partnering with the Pros: The Supply Chain Network

To understand where the Tank is made, you need to look beyond Irvine. Rezvani works with a global network of suppliers and subcontractors. Some of the key partners include:

- Armor specialists in the U.S. and Europe: Companies that provide ballistic glass, Kevlar panels, and blast-resistant materials.

- Electronics manufacturers in California and Texas: For systems like the thermal imaging camera, smoke screen, and drone deployment.

- Performance tuning shops in Michigan and Arizona: Where the engine (a 6.4L V8 or optional supercharged 7.0L) is upgraded for maximum power.

- Interior craftsmen in California and Italy: For luxury finishes like hand-stitched leather and carbon fiber trim.

This collaborative model allows Rezvani to focus on what they do best—design and integration—while letting experts handle specialized components. It’s like building a dream team for your car.

Assembly: A Hybrid Process

The actual assembly of the Rezvani Tank happens in phases:

- Base vehicle prep: A Jeep Wrangler is delivered to Irvine, where it’s disassembled and modified.

- Body and armor installation: The custom Rezvani body panels (made from lightweight composite materials) are fitted, and armor systems are added.

- Engine and drivetrain upgrades: The engine is tuned, and performance parts are installed—often at partner facilities.

- Interior and tech integration: The cabin is customized with luxury finishes, and advanced systems like night vision are calibrated.

- Final assembly and testing: The Tank is reassembled in Irvine and undergoes rigorous testing before delivery.

So, while the Tank’s “birthplace” is Irvine, its DNA is global. It’s a true product of collaboration.

The Role of Technology and Innovation in Manufacturing

How Rezvani Leverages Modern Tech

Building a car like the Tank isn’t just about hammers and wrenches. Rezvani uses cutting-edge technology at every step. For example:

- 3D printing: Custom brackets, interior panels, and even small armor components are 3D printed for precision and speed.

- CAD/CAM software: Every design is modeled digitally, allowing engineers to simulate stress, aerodynamics, and fit before cutting metal.

- Robotics and automation: While not fully automated, robotic arms assist with welding and alignment to ensure consistency.

- AI-driven testing: Systems like the EMP shield and thermal camera are tested using AI algorithms to simulate real-world conditions.

This tech-forward approach is one reason Rezvani can offer such advanced features while keeping production agile.

Customization: The Key to the Tank’s Appeal

One of the Tank’s biggest selling points is its customizability. Unlike mass-produced SUVs, each Tank is built to order. Want bulletproof glass? Done. Need a smoke screen and strobe lights? Sure. Prefer a stealth black interior with gold stitching? No problem.

This means Rezvani’s manufacturing process is highly flexible. The Irvine team works closely with customers to tailor each vehicle. For example, if a client wants a “Military Package” (with armor, EMP protection, and a drone), the order is sent to the relevant partners. The drone might come from a Texas-based tech firm, the EMP system from a defense contractor in Virginia, and the armor from a European specialist. Once everything arrives, it’s integrated in Irvine.

This level of customization is rare in the auto industry. Most manufacturers can’t (or won’t) offer it because it’s too complex. But for Rezvani, it’s part of the brand’s identity.

Quality Control: Ensuring Every Tank Is Battle-Ready

With so many custom components, quality control is critical. Rezvani has a multi-step testing process:

- Component testing: Each part is inspected before installation. Armor is tested with ballistics simulations; electronics are stress-tested.

- Assembly checks: Technicians verify fit and finish at every stage. Even small gaps in armor can compromise safety.

- Road and off-road testing: Each Tank is driven for hundreds of miles in different conditions to ensure reliability.

- Customer handover: Before delivery, a final review is done with the buyer to confirm all features work.

This meticulous process is why Rezvani can stand behind its claim: “Built for the impossible.”

Challenges and Limitations of the Manufacturing Model

The Pros of a Boutique Approach

Rezvani’s hybrid manufacturing model has clear advantages:

- Speed to market: By using existing platforms (like the Jeep Wrangler), Rezvani can launch new models faster than traditional automakers.

- Cost efficiency: They don’t need massive factories or R&D budgets. They focus on design and integration.

- Flexibility: Customization is easier because they’re not locked into a fixed production line.

- Innovation: They can experiment with new tech without long development cycles.

For a small company, this is a smart way to compete with giants like Lamborghini or Tesla.

The Cons: What’s Not Perfect

But the model isn’t flawless. Here are some challenges:

- Supply chain delays: If a partner is late (e.g., an armor shipment from Europe), the whole build can stall.

- Quality inconsistency: While rare, a poorly made component from a third party can slip through.

- Higher costs: Custom parts and labor-intensive assembly make the Tank expensive—starting at around $200,000.

- Limited scalability: Rezvani can’t produce thousands of Tanks a year. They’re limited to a few hundred annually.

These aren’t deal-breakers, but they’re important to know if you’re considering a Tank. It’s not a mass-market SUV—it’s a niche product.

Real-World Example: A Customer’s Experience

Take Mark T., a tech entrepreneur from Texas who bought a Tank in 2022. “I wanted something unique,” he told us. “Not just a luxury SUV, but a car that could handle anything.” His Tank has the Military Package, a supercharged engine, and a custom interior.

But the build took four months—longer than expected. “There was a delay with the armor,” Mark explained. “It came from Germany, and there was a customs hold.” Still, he was happy with the result. “It’s worth the wait. This car turns heads everywhere.”

Mark’s story highlights the trade-offs: You get a one-of-a-kind vehicle, but you need patience.

Comparing Rezvani’s Process to Traditional Automakers

How Big Brands Do It Differently

Let’s compare Rezvani to a traditional automaker like Ford or Mercedes:

| Aspect | Rezvani Tank | Traditional SUV (e.g., Ford Explorer) |

|---|---|---|

| Manufacturing | Hybrid: Irvine HQ + global partners | Centralized: Large factories (e.g., Kentucky Truck Plant) |

| Customization | Highly customizable (per customer order) | Limited options (pre-set trims and packages) |

| Production Volume | ~200-300 units/year | ~100,000+ units/year |

| Tech Integration | Custom systems (e.g., EMP, drone) | Standardized tech (e.g., SYNC, MBUX) |

| Lead Time | 3-6 months (custom build) | 1-2 weeks (dealer stock) |

This table shows the key differences. Rezvani trades volume and speed for uniqueness and innovation.

Why This Model Works for Rezvani

For a company like Rezvani, the boutique model is a strength. It allows them to:

- Focus on premium customers who value exclusivity.

- Stay agile and respond quickly to trends (e.g., adding new tech features).

- Maintain brand identity as a maker of “unstoppable” vehicles.

It’s not for everyone, but it’s perfect for their niche.

The Future of Rezvani: Where Will the Next Tank Be Made?

Expansion Plans and New Facilities

Rezvani isn’t standing still. In 2023, the company announced plans to open a second facility in Arizona, focused on performance tuning and off-road testing. This will reduce reliance on third-party shops and speed up builds.

They’re also exploring electric and hybrid versions of the Tank. An EV model would require new partnerships with battery and motor suppliers—possibly in Nevada or Michigan. This could shift some manufacturing to new locations.

Sustainability and Innovation

As the auto industry goes green, Rezvani is adapting. Future Tanks may use:

- Recycled materials for armor and interiors.

- Solar panels on the roof to power auxiliary systems.

- AI-driven diagnostics to monitor wear and tear in real time.

These changes could make the Tank even more advanced—and more sustainable.

What This Means for Buyers

If you’re thinking about a Rezvani Tank, here’s what to expect:

- More customization options as Rezvani adds new tech.

- Faster delivery times with expanded facilities.

- New models, like the Tank X (a smaller, off-road-focused version).

The future of the Tank is bright—and it’s being built, one custom part at a time.

Conclusion: The Soul of the Tank Is in Its Craft

So, where is the Rezvani Tank made? The answer is: everywhere and nowhere at once. It’s designed in California, built with global parts, and assembled with care in Irvine. It’s a product of collaboration, innovation, and a relentless pursuit of the extraordinary.

But more than that, the Tank is a symbol of what’s possible when you don’t follow the rules. Rezvani didn’t build a factory. They built a dream. And for the people who drive it, that’s all that matters. Whether you’re a security expert, a car enthusiast, or just someone who wants to stand out, the Tank is more than a vehicle—it’s a story. And now you know where that story begins.

Frequently Asked Questions

Where is the Rezvani Tank made?

The Rezvani Tank is manufactured in Irvine, California, at Rezvani Motors’ headquarters and production facility. This Southern California hub handles everything from design to final assembly of the military-inspired SUV.

Is the Rezvani Tank built in the USA?

Yes, the Rezvani Tank is proudly built in the USA. Its manufacturing and assembly take place entirely in Irvine, California, ensuring high-quality craftsmanship and adherence to strict safety standards.

What materials are used to make the Rezvani Tank?

The Rezvani Tank features a reinforced steel chassis, ballistic armor (optional), and carbon fiber or composite body panels for durability. These materials contribute to its rugged, off-road-ready design and premium finish.

Where is Rezvani Motors located, and how does it impact Tank production?

Rezvani Motors is based in Irvine, California—the same location where the Tank is made. Centralizing design, engineering, and manufacturing allows for tighter quality control and rapid innovation.

Are Rezvani Tank parts sourced locally in California?

While some components (like engines and transmissions) are sourced globally, many parts are sourced from U.S. suppliers. Final assembly and customization happen at the Irvine facility to maintain the vehicle’s high standards.

Why is the Rezvani Tank made in California instead of overseas?

Building the Rezvani Tank in California enables direct oversight of production, faster prototyping, and alignment with the brand’s luxury-performance ethos. Local manufacturing also supports American jobs and supply chains.