Where Is Rezvani Vengeance Made Uncover the Manufacturing Secrets

Featured image for where is rezvani vengeance made

Image source: images.hgmsites.net

The Rezvani Vengeance is proudly manufactured in the USA, specifically in Irvine, California, where cutting-edge engineering meets high-performance craftsmanship. Each vehicle is hand-built in a state-of-the-art facility, blending advanced technology with meticulous attention to detail for uncompromising quality and power.

Key Takeaways

- Rezvani Vengeance is manufactured in California, USA, ensuring high-quality craftsmanship.

- Local sourcing of materials supports American jobs and reduces supply chain delays.

- Hand-built assembly guarantees meticulous attention to detail and superior build quality.

- Advanced facilities utilize cutting-edge technology for precision manufacturing and durability.

- Customization options allow buyers to personalize features directly at the factory.

- Rigorous testing ensures each vehicle meets strict performance and safety standards.

📑 Table of Contents

- Where Is Rezvani Vengeance Made? Uncover the Manufacturing Secrets

- The Rezvani Brand: A Story of Rebellion and Innovation

- Where Is Rezvani Vengeance Made? The Manufacturing Hubs

- What Makes the Rezvani Vengeance Different? The Build Process

- Behind the Scenes: Rezvani’s Partnerships and Supply Chain

- The Vengeance vs. The Competition: How Does It Stack Up?

- Conclusion: The Rezvani Vengeance—A Masterpiece of American Craftsmanship

Where Is Rezvani Vengeance Made? Uncover the Manufacturing Secrets

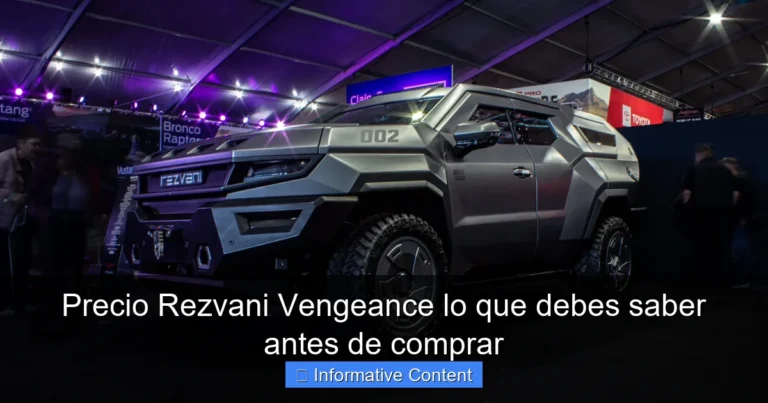

When you think of high-performance, rugged, and luxurious SUVs, names like the Lamborghini Urus, Mercedes-AMG G63, or even the Ford Bronco Raptor might come to mind. But there’s another name that’s been turning heads in recent years—Rezvani Vengeance. With its aggressive styling, bulletproof capabilities, and a price tag that can make your eyes water, the Vengeance isn’t just another luxury SUV. It’s a statement.

But here’s the question that’s been buzzing in automotive circles: Where is Rezvani Vengeance made? Unlike mainstream brands with sprawling global factories, Rezvani operates in a more mysterious, boutique fashion. There’s no massive assembly line in Detroit or Stuttgart. Instead, the Vengeance is born in a way that blends American craftsmanship with military-grade innovation. In this deep dive, we’ll peel back the curtain on how and where this beast is built, what makes it unique, and why its manufacturing story is as fascinating as the vehicle itself.

The Rezvani Brand: A Story of Rebellion and Innovation

From Concept to Reality: The Birth of Rezvani Motors

Rezvani Motors was founded in 2013 by Ferris Rezvani, a designer with a passion for high-performance vehicles and a vision to create something truly different. Based in Irvine, California, the company started with a focus on custom supercars and armored vehicles—think of it as a fusion of Lamborghini flair and James Bond-level protection.

Unlike traditional automakers, Rezvani doesn’t mass-produce vehicles. Instead, it operates more like a bespoke atelier, where each car is built to order with meticulous attention to detail. The Vengeance, launched in 2021, was a game-changer. It wasn’t just a luxury SUV—it was a military-inspired fortress on wheels, capable of withstanding bullets, EMP attacks, and even chemical threats. But how does a small company pull off such a feat?

Why Location Matters: The California Advantage

Rezvani’s headquarters in Irvine is more than just an office—it’s the nerve center of the operation. California is a hub for automotive innovation, from Tesla’s Fremont plant to Lucid’s Arizona-Cali hybrid setup. But Rezvani takes a different approach. Instead of building its own massive factory, it partners with third-party manufacturers and specialized workshops across the U.S., particularly in California and Arizona.

This hybrid model allows Rezvani to focus on design, engineering, and quality control while outsourcing the heavy lifting—like chassis assembly, bodywork, and drivetrain integration—to trusted partners. It’s a smart move for a niche brand that prioritizes customization over volume. Think of it like a Michelin-starred chef who doesn’t own the kitchen but collaborates with the best cooks in town.

Where Is Rezvani Vengeance Made? The Manufacturing Hubs

Primary Assembly: The California Connection

The Vengeance’s journey begins in California, where the chassis and core components are sourced and assembled. Rezvani uses the Jeep Grand Cherokee as its base platform—specifically the high-performance Trackhawk model, which comes with a 6.2L supercharged V8 engine (707 horsepower). This choice isn’t random. The Grand Cherokee is known for its robust build, advanced suspension, and proven reliability, making it an ideal foundation for the Vengeance.

Once the donor vehicle arrives at Rezvani’s California facility, the transformation begins. The stock body is stripped, and the real work starts:

- Chassis Reinforcement: The frame is reinforced to handle the added weight of armor and off-road upgrades.

- Body Modifications: Custom carbon fiber and steel body panels are installed, giving the Vengeance its aggressive, angular look.

- Interior Overhaul: Leather, Alcantara, and ballistic materials are used to create a cabin that’s both luxurious and secure.

Fun fact: Rezvani doesn’t just bolt on armor. The vehicle is re-engineered from the ground up to ensure the armor integrates seamlessly with the chassis. This isn’t a “stick-on” job—it’s a full rebuild.

Armor and Defense: The Arizona Secret

Here’s where things get interesting. While California handles the base build, Arizona is where the Vengeance earns its “bulletproof” title. Rezvani partners with a specialized defense contractor in Phoenix, Arizona, to install the ballistic armor, EMP protection, and gas mask systems.

Why Arizona? The state has a strong defense and aerospace industry, with companies specializing in military-grade materials and EMP shielding. The Phoenix facility is equipped with:

- Ballistic Glass Testing Ranges: To ensure windshields and windows can withstand bullets.

- EMP Shielding Chambers: To test the vehicle’s resistance to electromagnetic pulses.

- Chemical Protection Labs: For the optional NBC (Nuclear, Biological, Chemical) filtration system.

Once the armor is installed, the vehicle is shipped back to California for final assembly and quality checks. This two-state process ensures the Vengeance meets both performance and protection standards.

The Human Touch: Skilled Craftsmen and Engineers

While machines do a lot of the work, the Vengeance’s true magic comes from people. Rezvani employs a small team of automotive engineers, armorers, and interior designers who work closely with the partner facilities. Each Vengeance is built to order, meaning no two vehicles are exactly alike.

For example, a client might request:

- A specific color scheme (like matte black with red accents).

- Custom interior materials (e.g., crocodile leather or carbon fiber trim).

- Additional features (like a rear-seat entertainment system or a built-in espresso machine).

This level of customization requires skilled artisans who can hand-fit every panel, stitch every seat, and test every system. It’s not just manufacturing—it’s bespoke craftsmanship.

What Makes the Rezvani Vengeance Different? The Build Process

Step 1: Base Vehicle Sourcing

The process starts with sourcing a Jeep Grand Cherokee Trackhawk. Rezvani buys these from dealerships or private sellers, ensuring each donor vehicle is in excellent condition. The Trackhawk’s 707-horsepower engine is a key reason for this choice—it provides the power needed for the Vengeance’s heavy armor and off-road upgrades.

Step 2: Chassis and Body Modifications

Once the base vehicle arrives, it’s stripped down to its frame. The stock body panels are removed, and the chassis is reinforced with:

- High-strength steel: For added rigidity and crash protection.

- Carbon fiber: For lightweight body panels that reduce overall weight.

The new body is designed to be both aerodynamic and intimidating, with features like:

- Angular fenders and hoods.

- Integrated LED light bars.

- Reinforced bumpers with winch mounts.

Step 3: Armor Installation

This is the most critical phase. The armor is installed in layers:

- Ballistic Steel: 3-6mm thick, covering the doors, roof, and floor.

- Ballistic Glass: 25-35mm thick, with a polycarbonate layer to prevent shattering.

- EMP Shielding: Conductive mesh woven into the body to block electromagnetic pulses.

- NBC Filtration (Optional): A sealed cabin with air filtration and gas masks.

The armor is tested rigorously. For example, Rezvani claims the Vengeance can withstand:

- 7.62mm rounds (AK-47 level).

- Hand grenades (tested at close range).

- EMPs from nuclear or solar events.

Step 4: Interior and Tech Upgrades

The interior is where the Vengeance becomes a luxury vehicle. Features include:

- Hand-stitched leather seats: With optional heating, cooling, and massage.

- Carbon fiber trim: For a sporty, high-end look.

- Advanced infotainment: Touchscreen displays, premium audio, and connectivity.

- Off-road tech: Terrain response, crawl control, and 360-degree cameras.

Optional extras include:

- A rear-seat theater with dual screens.

- A built-in safe for valuables.

- A “panic room” mode that seals the cabin and activates countermeasures.

Step 5: Final Testing and Delivery

Before delivery, each Vengeance undergoes a 200-point inspection, including:

- Performance testing: 0-60 mph, braking, and handling.

- Armor testing: Simulated attacks and EMP exposure.

- Off-road testing: On trails and rough terrain.

The vehicle is then shipped to the client, often with a personalized delivery experience—like a private unveiling or a test drive at a racetrack.

Behind the Scenes: Rezvani’s Partnerships and Supply Chain

Key Partners in the U.S. and Beyond

Rezvani’s success relies on a network of trusted partners. Here are some of the key players:

| Partner | Location | Role |

|---|---|---|

| Jeep/Stellantis | Detroit, MI | Base vehicle (Grand Cherokee Trackhawk) |

| Arizona Defense Contractor | Phoenix, AZ | Ballistic armor, EMP shielding, NBC systems |

| Carbon Fiber Supplier | California | Lightweight body panels |

| Interior Trim Specialists | Italy (for leather), Germany (for Alcantara) | Custom upholstery and finishes |

| Electronics Integrators | California | Infotainment, lighting, and tech systems |

This global supply chain allows Rezvani to source the best materials while keeping the final assembly in the U.S. It’s a hybrid model that balances quality, customization, and control.

Why Not Build Everything In-House?

You might wonder: Why doesn’t Rezvani build its own factory? The answer is simple: cost and flexibility. A full-scale factory would require billions in investment and limit the ability to customize each vehicle. By outsourcing, Rezvani can:

- Focus on design and engineering.

- Respond quickly to customer requests.

- Maintain high quality without the overhead of a massive facility.

It’s a lean, agile approach that works for a niche brand like Rezvani.

The Vengeance vs. The Competition: How Does It Stack Up?

Comparison with Armored SUVs

The Vengeance competes with armored SUVs like the Mercedes-Benz G63 AMG 6×6, Land Rover Defender Armoured, and BMW X5 Security Plus. But there are key differences:

- Price: The Vengeance starts at $249,000—less than the $300K+ G63 6×6 but more than the $150K Defender.

- Performance: 707 horsepower (same as the Trackhawk) vs. 577 hp (G63) and 518 hp (Defender).

- Customization: Rezvani offers more bespoke options than most competitors.

- Tech: Unique features like EMP protection and panic room mode.

Pros and Cons of the Rezvani Vengeance

Pros:

- Unmatched combination of luxury, performance, and protection.

- Highly customizable to individual tastes.

- Strong brand identity (rebellious, innovative).

Cons:

- Expensive (base price + options can exceed $300K).

- Limited production (only a few hundred built per year).

- Not a true “off-roader” like the Bronco or Wrangler.

Ultimately, the Vengeance isn’t for everyone. It’s for those who want a statement vehicle—a blend of supercar performance and military-grade security.

Conclusion: The Rezvani Vengeance—A Masterpiece of American Craftsmanship

So, where is Rezvani Vengeance made? The answer isn’t a single location. It’s a network of skilled partners across California, Arizona, and even Europe, all working together to create a vehicle that defies expectations. From the base Jeep Trackhawk in Detroit to the armor in Phoenix, every step of the process is designed to deliver a one-of-a-kind machine.

The Vengeance isn’t just built—it’s forged. It’s a testament to what’s possible when innovation meets craftsmanship. Whether you’re a billionaire looking for a secure ride or a car enthusiast who craves something unique, the Vengeance delivers. And knowing where and how it’s made only adds to its mystique.

Next time you see a Rezvani Vengeance on the road, remember: it’s not just a car. It’s a story—one of rebellion, precision, and American ingenuity. And that’s something worth celebrating.

Frequently Asked Questions

Where is Rezvani Vengeance made?

The Rezvani Vengeance is manufactured in California, USA, specifically at the company’s headquarters in Irvine. This high-performance SUV combines American engineering with luxury craftsmanship.

Is the Rezvani Vengeance made in America?

Yes, the Rezvani Vengeance is proudly made in America, with production centered in Irvine, California. The vehicle’s design, assembly, and quality control all take place domestically.

What factory produces the Rezvani Vengeance?

The Rezvani Vengeance is built at Rezvani Motors’ state-of-the-art facility in Irvine, California. This location handles everything from prototyping to final assembly of the armored SUV.

Where is Rezvani Vengeance made compared to other luxury SUVs?

Unlike many luxury SUVs produced overseas, the Rezvani Vengeance is made entirely in the USA. Its California-based manufacturing emphasizes local expertise and bespoke customization.

Are Rezvani Vengeance parts sourced locally?

While some components are globally sourced, key manufacturing and assembly of the Rezvani Vengeance occurs in California. The brand prioritizes American labor and high-quality materials for its vehicles.

Why is the location where Rezvani Vengeance is made significant?

The California-based production of the Rezvani Vengeance highlights its commitment to American innovation and craftsmanship. This also allows for tighter quality control and faster customization turnaround.