Who Makes Ford Electric Car Batteries and How They Power the Future

Featured image for who makes ford electric car batteries

Image source: images.carexpert.com.au

Ford electric car batteries are primarily manufactured by SK On, a leading South Korean battery producer, through a joint venture called BlueOval SK, established to power Ford’s growing lineup of EVs. This strategic partnership ensures cutting-edge lithium-ion battery production at scale, supporting Ford’s ambitious electrification goals and North American supply chain independence.

Key Takeaways

- Ford manufactures its own batteries through partnerships and in-house production for full control.

- SK Innovation is a key partner supplying advanced lithium-ion batteries for Ford EVs.

- New BlueOval SK joint venture boosts U.S. battery production and job creation.

- Solid-state battery research aims to deliver longer range and faster charging.

- Battery plants in Kentucky and Tennessee support Ford’s 2030 EV expansion goals.

- Recycling programs reduce waste and promote sustainable battery lifecycle management.

📑 Table of Contents

- Who Makes Ford Electric Car Batteries and How They Power the Future

- The Core Partnership: Who Actually Builds Ford’s EV Batteries?

- How Ford’s Battery Strategy Supports Its EV Vision

- Battery Chemistry and Technology: What’s Inside Ford’s EVs?

- Real-World Performance: How Ford Batteries Stack Up

- The Road Ahead: How Ford’s Battery Plans Shape the Future

- Conclusion: Powering the Future, One Battery at a Time

Who Makes Ford Electric Car Batteries and How They Power the Future

Picture this: You’re driving down a quiet suburban road in your Ford Mustang Mach-E, the hum of the electric motor replacing the roar of a traditional engine. The sun is setting, and the dashboard glows softly with your next turn. But as you cruise, a thought pops up: Who actually made the battery that’s powering this smooth, quiet ride? It’s a question more drivers are asking as Ford dives headfirst into the electric vehicle (EV) revolution.

Ford’s shift toward electric mobility isn’t just about flashy new models like the F-150 Lightning or the E-Transit van. At the heart of every Ford EV is a battery—a complex, high-tech powerhouse that determines how far you can drive, how fast you can charge, and how long your car will last. But Ford doesn’t build these batteries in-house like some tech companies. Instead, they partner with global leaders in battery manufacturing to deliver reliable, high-performance energy storage. In this deep dive, we’ll explore who makes Ford electric car batteries, how these partnerships work, and what they mean for the future of transportation. Whether you’re a current EV owner, a curious car enthusiast, or someone considering your first electric Ford, this guide will give you the real story behind the tech that powers your drive.

The Core Partnership: Who Actually Builds Ford’s EV Batteries?

When it comes to battery manufacturing, Ford has chosen a strategic path: collaboration over competition. Rather than reinvent the wheel, Ford has teamed up with established battery giants to ensure quality, scalability, and innovation. The primary name you’ll hear in this space is SK On, a South Korean battery manufacturer and a subsidiary of SK Innovation. But Ford’s battery ecosystem is more than just one partner—it’s a growing network of alliances built to meet rising demand.

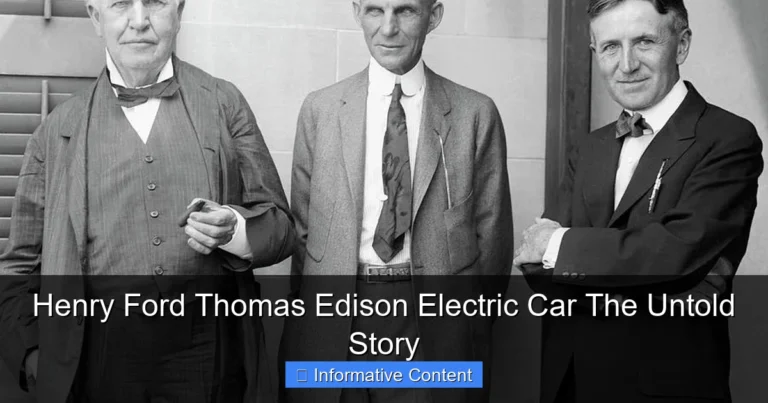

Visual guide about who makes ford electric car batteries

Image source: financialfuelservices.com

SK On: Ford’s Longtime Battery Ally

SK On has been Ford’s go-to battery supplier for several years, especially for its early EV models. The partnership kicked off with the Ford Escape Plug-in Hybrid and has since expanded to the Mustang Mach-E and F-150 Lightning. These batteries use NMC (Nickel Manganese Cobalt) chemistry, which strikes a balance between energy density, longevity, and cost. For example, the Mach-E’s Extended Range battery (88 kWh) is built by SK On and delivers up to 314 miles of range on a single charge.

What makes SK On stand out? Their focus on cell-to-pack (CTP) technology, which eliminates the need for individual module housings. This means more battery cells fit into the same space, boosting energy density and reducing weight—critical for performance and range. SK On also invests heavily in solid-state battery research, which could revolutionize EVs in the next decade.

LG Energy Solution: A Growing Role in Ford’s Lineup

While SK On leads the charge, LG Energy Solution (LGES) is playing an increasingly important role. LG has supplied batteries for Ford’s E-Transit commercial vans and is expected to contribute to future models. LGES is known for its NCMA (Nickel Cobalt Manganese Aluminum) batteries, which reduce cobalt content—lowering costs and ethical concerns around mining.

LG’s batteries are praised for their thermal stability and fast-charging capabilities. For instance, the E-Transit can charge from 15% to 80% in about 34 minutes using a DC fast charger, thanks in part to LG’s efficient thermal management design. Ford’s collaboration with LG isn’t just about supply—it’s about co-developing next-gen battery chemistries that are safer and more sustainable.

Ford’s Own Battery Ventures: BlueOval SK and Beyond

Here’s where things get really exciting: Ford isn’t just buying batteries—they’re building their own manufacturing capacity. In 2021, Ford and SK On formed a joint venture called BlueOval SK, with plans to build three massive battery plants in the U.S. by 2026. These facilities—located in Kentucky (two plants) and Tennessee (one plant)—will produce batteries exclusively for Ford and Lincoln EVs.

Once fully operational, BlueOval SK is expected to produce enough batteries for over 1 million Ford EVs per year. That’s a game-changer for Ford’s supply chain, reducing reliance on imports and cutting delivery times. The Tennessee plant alone will be one of the largest battery factories in North America, spanning 3,600 acres and creating thousands of jobs.

How Ford’s Battery Strategy Supports Its EV Vision

Ford’s approach to battery sourcing isn’t just about who builds the batteries—it’s about why and how they’re doing it. With a goal of selling 2 million EVs annually by 2026, Ford needs a bulletproof battery strategy. Let’s break down the key pillars of their plan.

Localizing Production for Speed and Sustainability

One of Ford’s biggest moves is bringing battery manufacturing closer to home. By building BlueOval SK plants in the U.S., Ford reduces shipping distances, cuts carbon emissions, and avoids supply chain delays. For example, shipping batteries from South Korea to Michigan can take weeks and increase the vehicle’s overall carbon footprint. Local production slashes that.

This “Made in America” strategy also appeals to consumers and policymakers. With the U.S. Inflation Reduction Act offering tax credits for EVs with domestically sourced batteries, Ford’s local plants could make their vehicles more affordable for buyers. It’s a win-win: lower emissions, faster delivery, and better incentives.

Diversifying Suppliers to Avoid Bottlenecks

Ford learned a hard lesson during the global chip shortage: relying on a single supplier is risky. That’s why they’re working with both SK On and LGES, plus exploring partnerships with other players. Diversification means if one supplier faces delays (say, due to geopolitical issues or natural disasters), Ford can shift production to another.

For example, during the early rollout of the F-150 Lightning, Ford temporarily used LG batteries in some units when SK On faced production hiccups. This flexibility kept the line moving and deliveries on schedule. It’s a smart backup plan that every automaker should consider.

Investing in Next-Gen Battery Tech

While current Ford EVs use NMC and NCMA batteries, the company is already looking ahead. Ford has invested in startups like QuantumScape, a leader in solid-state battery research. Solid-state batteries promise higher energy density, faster charging, and improved safety—no flammable liquid electrolytes, which reduces fire risk.

Ford has also partnered with Redwood Materials, a battery recycling company founded by Tesla co-founder JB Straubel. This partnership focuses on recovering valuable materials like lithium, nickel, and cobalt from used EV batteries. By recycling, Ford can reduce its need for new mining, lower costs, and shrink its environmental footprint. It’s a circular economy approach that could define the future of EV manufacturing.

Battery Chemistry and Technology: What’s Inside Ford’s EVs?

Not all batteries are created equal. The type of battery chemistry used in a Ford EV directly affects range, charging speed, lifespan, and even safety. Let’s peel back the layers and see what powers your Mach-E or Lightning.

NMC (Nickel Manganese Cobalt): The Workhorse of Today’s EVs

Most Ford EVs run on NMC batteries, particularly the 811 variant (8 parts nickel, 1 part manganese, 1 part cobalt). This chemistry offers high energy density, meaning more power in a smaller space. It’s ideal for performance-oriented vehicles like the Mach-E GT, which uses an 88 kWh NMC battery to deliver 480 horsepower and 270 miles of range.

But NMC isn’t perfect. Cobalt is expensive and often linked to unethical mining practices in the Democratic Republic of Congo. To address this, Ford and its suppliers are reducing cobalt content over time. LG’s NCMA batteries, for example, cut cobalt by 20% compared to traditional NMC.

LFP (Lithium Iron Phosphate): The Budget-Friendly Option

Ford has started offering LFP (Lithium Iron Phosphate) batteries in some models, starting with the base-level Mustang Mach-E in 2023. LFP batteries are cheaper, safer, and more durable than NMC—but they have lower energy density, which means less range.

The base Mach-E with an LFP battery gets about 247 miles of range, compared to 314 miles with the Extended Range NMC version. But for city drivers or those who don’t need long-range, LFP is a smart choice. It also charges faster in cold weather and lasts longer—some LFP batteries can handle 1,000+ charge cycles with minimal degradation.

Tip: If you mainly drive short distances and want a lower upfront cost, consider an LFP-equipped Ford EV. You’ll save money and get a battery that’s less prone to thermal runaway (a fancy term for battery fires).

Thermal Management: Keeping Batteries Happy

EV batteries hate extreme temperatures. Too hot? They degrade faster. Too cold? They lose range. That’s why Ford uses advanced liquid cooling systems in most of its EVs. These systems circulate coolant through channels around the battery cells, keeping temperatures within an optimal range (usually 20–30°C or 68–86°F).

The F-150 Lightning, for example, can precondition its battery before charging. If you plug in while the battery is cold, the truck automatically warms it up—so you get faster charging and better range. It’s a small feature, but it makes a big difference in winter.

Real-World Performance: How Ford Batteries Stack Up

Let’s get practical. How do Ford’s batteries perform in everyday driving? We’ll look at real-world data, user experiences, and expert reviews to see how they hold up.

Range and Charging: What You Can Expect

Ford’s EVs offer solid range, but real-world performance depends on driving habits, weather, and terrain. Here’s a quick comparison of key models:

| Model | Battery Type | Usable Capacity | EPA Range | DC Fast Charge Speed |

|---|---|---|---|---|

| Mustang Mach-E Standard Range | LFP | 70 kWh | 247 miles | 150 kW (15-80% in ~38 min) |

| Mustang Mach-E Extended Range | NMC | 88 kWh | 314 miles | 150 kW (10-80% in ~45 min) |

| F-150 Lightning (Standard) | NMC | 98 kWh | 240 miles | 150 kW (15-80% in ~41 min) |

| F-150 Lightning (Extended) | NMC | 131 kWh | 320 miles | 150 kW (15-80% in ~44 min) |

| E-Transit (High Roof) | NCMA | 68 kWh | 126 miles | 115 kW (15-80% in ~34 min) |

Note: Charging speeds vary by charger type, temperature, and battery state. Always use Ford’s FordPass Charging Network app to find compatible fast chargers.

Longevity and Warranty: Peace of Mind for Owners

Ford offers an 8-year/100,000-mile warranty on all EV batteries, covering defects and excessive degradation (defined as losing more than 30% capacity). In practice, most Ford EV batteries last well beyond that. Real-world data from owners shows minimal degradation after 50,000 miles—especially with LFP models.

Tip: To extend battery life, avoid frequent deep discharges (below 20%) and limit fast charging to 80% unless you need the full range. Think of it like your smartphone: occasional full charges are fine, but constant 0–100% cycles wear it down faster.

The Road Ahead: How Ford’s Battery Plans Shape the Future

Ford’s battery story is just beginning. With billions invested in new plants, recycling, and next-gen tech, the company is positioning itself as a leader in the EV space. But the road ahead has challenges—and opportunities.

Scaling Up: Meeting Demand Without Compromising Quality

Building three massive battery plants is no small feat. Ford and SK On face pressure to ramp up production quickly while maintaining strict quality control. Any battery defect could lead to costly recalls—like the ones seen with other automakers in recent years.

To mitigate risk, Ford is using AI-driven quality checks and real-time monitoring at its factories. They’re also training thousands of new workers in battery assembly and safety protocols. It’s a big investment, but one that could pay off in reliability and trust.

Sustainability: From Mine to Recycling Loop

Ford’s partnership with Redwood Materials isn’t just about recycling—it’s about redefining the battery lifecycle. By 2030, Ford aims to recycle 95% of materials from used EV batteries and use 100% recycled cobalt in new ones. They’re also working with mining companies to ensure ethical sourcing.

This focus on sustainability could give Ford a competitive edge. As consumers and regulators demand greener vehicles, a transparent, eco-friendly battery supply chain will be a major selling point.

Innovation: Beyond Today’s Batteries

While NMC and LFP dominate today, Ford is betting on the future. Solid-state batteries could arrive in Ford EVs by 2027, offering double the range and 15-minute fast charging. They’re also exploring battery swapping for commercial fleets—imagine a delivery van pulling into a station and swapping its battery in under 10 minutes.

These innovations won’t happen overnight, but Ford’s aggressive R&D spending (over $50 billion through 2026) shows they’re serious about leading the next wave of EV tech.

Conclusion: Powering the Future, One Battery at a Time

So, who makes Ford electric car batteries? It’s not one single company—it’s a dynamic ecosystem of partners, joint ventures, and in-house innovation. From SK On’s high-performance NMC cells to LG’s efficient NCMA tech, and Ford’s own BlueOval SK factories, the battery story is one of collaboration, ambition, and forward-thinking.

What does this mean for you? It means Ford EVs are built with reliable, cutting-edge batteries that balance range, safety, and sustainability. Whether you’re driving a Mach-E to work, an F-150 Lightning to a job site, or an E-Transit across town, you’re riding on battery tech that’s designed to last—and evolve.

As Ford continues to invest in local production, recycling, and next-gen chemistry, their batteries won’t just power cars—they’ll power a cleaner, smarter future. And the best part? You’re not just a passenger. You’re part of the journey.

Frequently Asked Questions

Who makes Ford electric car batteries?

Ford electric car batteries are primarily manufactured through partnerships with major battery suppliers like SK Innovation (now SK On) and LG Energy Solution. These collaborations power Ford’s current EV lineup, including the F-150 Lightning and Mustang Mach-E.

Where does Ford source its EV battery cells?

Ford sources its EV battery cells from global leaders like SK On (USA and Hungary) and LG Energy Solution (Poland and Michigan). The automaker is also building its own battery plants in the U.S. to reduce reliance on third-party suppliers.

Is Ford making its own electric car batteries?

Yes, Ford is vertically integrating battery production through its Ford Ion Park R&D center and new BlueOval SK battery plants in Kentucky and Tennessee. These facilities will produce Ford-specific battery packs using proprietary lithium-ion and solid-state technologies.

What type of batteries do Ford electric cars use?

Most Ford EVs use lithium-ion batteries with nickel-manganese-cobalt (NMC) chemistry, optimized for energy density and longevity. Future models may incorporate lithium iron phosphate (LFP) batteries for cost efficiency and Ford’s next-gen solid-state batteries.

Who supplies Ford with electric car battery materials?

Ford partners with raw material suppliers like ioneer (lithium) and Compass Minerals (nickel) to secure ethical, sustainable sourcing. These partnerships support Ford’s goal of producing 2 million EVs annually by 2026.

How are Ford’s electric car batteries different from competitors?

Ford differentiates through its Modular Battery Platform, allowing flexible configurations across vehicle segments. The company also focuses on localized production (e.g., BlueOval City) to streamline supply chains and reduce costs.