Who Makes the Batteries for Ford Electric Cars Revealed

Featured image for who makes the batteries for ford electric cars

Image source: static.wixstatic.com

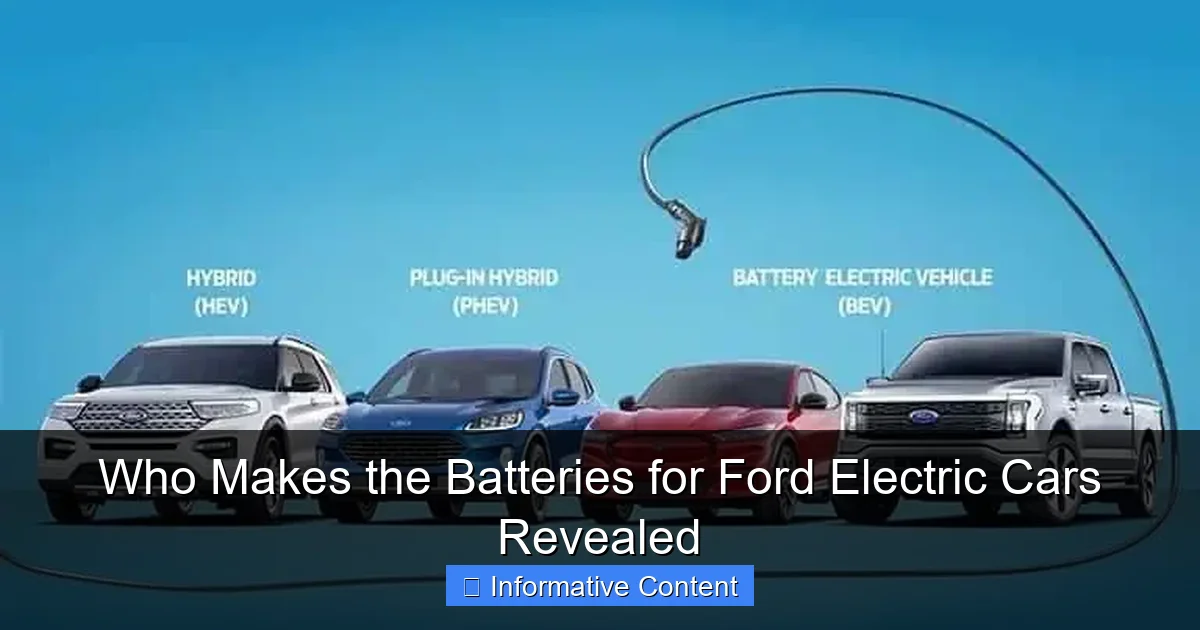

Ford electric car batteries are primarily manufactured by SK Innovation and LG Energy Solution, two global leaders in EV battery technology. Ford has also partnered with SK to build BlueOval SK, a joint venture producing next-gen batteries in the U.S. for models like the F-150 Lightning and Mustang Mach-E.

Key Takeaways

- Ford manufactures its own batteries via BlueOval SK joint venture.

- Lithium-ion cells are sourced globally but assembled in U.S. plants.

- SK Innovation supplies key battery tech and production expertise.

- Solid-state batteries are in development for future Ford EVs.

- Recycling programs aim to reuse 90% of battery materials by 2030.

- Local sourcing reduces costs and supply chain risks.

📑 Table of Contents

- Who Makes the Batteries for Ford Electric Cars Revealed

- The Big Players: Ford’s Battery Partners

- How Ford Assembles Batteries: From Cells to Packs

- The Future: Ford’s In-House Battery Revolution

- Battery Performance and Real-World Ownership

- The Bigger Picture: Sustainability and Ethics

- Conclusion: The Power Behind Ford’s Electric Future

Who Makes the Batteries for Ford Electric Cars Revealed

Imagine this: You’re driving down the highway in your new Ford Mustang Mach-E, the wind in your hair (well, metaphorically, since it’s an SUV), and the smooth hum of the electric motor is your only soundtrack. You glance at the battery indicator—80% charge—and wonder, “Who made this thing?” It’s a fair question, especially when the battery is the heart of any electric vehicle (EV). For Ford, a company with over a century of automotive history, the shift to electric is a massive leap. But unlike traditional engines, which Ford has built in-house for decades, EV batteries are a different beast. They’re complex, expensive, and require specialized knowledge. So, who’s behind the power in Ford’s electric cars?

You might assume Ford handles battery production entirely on its own, given its legacy. But the truth is more collaborative—and fascinating. Ford partners with some of the biggest names in battery tech to power its EVs, from the F-150 Lightning to the upcoming Explorer EV. In this post, we’ll dive into the who, the how, and the why behind Ford’s battery supply chain. Whether you’re an EV newbie or a seasoned car enthusiast, this breakdown will give you the inside scoop on what keeps Ford’s electric dreams running. And hey, if you’ve ever worried about battery lifespan or charging speed, we’ve got answers for those too.

The Big Players: Ford’s Battery Partners

SK On: The Korean Giant Behind the Mach-E and F-150 Lightning

If you drive a Ford Mustang Mach-E or F-150 Lightning, you’re likely powered by batteries from SK On, a South Korean battery manufacturer and subsidiary of SK Group. SK On has been Ford’s primary partner since 2021, supplying the lithium-ion cells that go into the high-voltage battery packs for these models. Think of SK On as the “Intel Inside” of Ford’s EVs—they’re not the carmaker, but their tech is critical to performance.

Visual guide about who makes the batteries for ford electric cars

Image source: yorkdaleford.com

SK On’s batteries use NCM (Nickel, Cobalt, Manganese) chemistry, which offers a strong balance of energy density, longevity, and safety. For example, the Mach-E’s extended-range battery (91 kWh) uses SK On cells to deliver up to 314 miles of range (EPA estimate). The F-150 Lightning’s larger 131 kWh battery (for the extended-range version) also relies on SK On’s technology, enabling it to power homes during outages (a feature Ford calls “Intelligent Backup Power”).

Pro tip: If you’re curious about your Ford EV’s battery origin, check the owner’s manual or the FordPass app. Ford often lists battery supplier details in the vehicle specifications section.

LG Energy Solution: A Backup Partner for Future Models

While SK On dominates current production, Ford has also partnered with LG Energy Solution, another South Korean battery leader. LG supplies cells for select Ford EVs, including the E-Transit van, and is expected to play a bigger role in future models. LG’s batteries use a similar NCM chemistry but with slight tweaks to improve thermal stability (a fancy way of saying they handle heat better, which is crucial for safety).

One key advantage of LG’s batteries? They’re often slightly cheaper to produce, which could help Ford keep prices competitive. For example, the E-Transit’s 68 kWh battery (with 126 miles of range) is priced lower than many rivals, partly due to LG’s cost-efficient manufacturing.

The Role of CATL: A Controversial but Critical Player

Here’s where things get interesting. Ford has a technology licensing agreement with CATL (Contemporary Amperex Technology Co. Limited), the world’s largest battery maker, based in China. Unlike SK On and LG, CATL doesn’t directly supply cells to Ford’s U.S. plants. Instead, Ford is building a battery plant in Michigan (called BlueOval Battery Park) that will produce LFP (Lithium Iron Phosphate) batteries using CATL’s patented technology. This setup avoids direct Chinese imports, which helps Ford comply with U.S. trade policies.

LFP batteries are a big deal because they’re cheaper, longer-lasting (up to 1 million miles in some cases!), and don’t require cobalt or nickel—materials tied to ethical and environmental concerns. Ford plans to use LFP batteries in the Mustang Mach-E starting in 2024 and the F-150 Lightning by 2025.

Why this matters: LFP batteries could make Ford’s EVs more affordable and sustainable. But some critics worry about relying on a Chinese tech partner. Ford’s solution? The Michigan plant will be Ford-owned and operated, with CATL only providing the “recipe” (not the ingredients).

How Ford Assembles Batteries: From Cells to Packs

The Journey from Raw Materials to Your Car

Ever wondered how a tiny battery cell becomes the massive pack under your EV’s floor? It’s a multi-step process, and Ford handles much of it in-house. Here’s the breakdown:

- Step 1: Cell Procurement – Ford buys cells from SK On, LG, or (eventually) its own Michigan plant. These cells are the “building blocks” of the battery.

- Step 2: Module Assembly – Cells are grouped into modules (think of them as battery “bricks”). Ford’s engineers design these modules to fit the vehicle’s shape. For example, the F-150 Lightning’s battery pack has 12 modules, each containing dozens of cells.

- Step 3: Pack Assembly – Modules are wired together, cooled (via liquid cooling systems), and encased in a protective shell. Ford’s Rawsonville Components Plant (Michigan) and Cuautitlán Plant (Mexico) handle this for the Mach-E and Lightning.

- Step 4: Software Integration – Ford’s proprietary software monitors each cell’s health, optimizing charging and preventing overheating.

Fun fact: The F-150 Lightning’s battery pack weighs over 1,800 pounds—roughly the weight of a small car! That’s why Ford uses lightweight materials like aluminum for the pack’s housing.

Quality Control: Ensuring Every Battery Meets Ford’s Standards

Ford doesn’t just slap batteries together and hope for the best. They test every pack rigorously. For example:

- Thermal Testing – Batteries are heated to 120°F (49°C) and cooled to -22°F (-30°C) to mimic extreme weather.

- Crash Testing – Packs are subjected to simulated collisions to ensure they won’t catch fire.

- Lifespan Testing – Batteries are charged/discharged thousands of times to simulate 10+ years of use.

Ford’s goal? A battery that lasts the life of the car (typically 8–10 years or 100,000 miles). If a pack fails, Ford offers an 8-year/100,000-mile warranty (whichever comes first), covering defects and capacity loss below 70%.

The Future: Ford’s In-House Battery Revolution

BlueOval: Ford’s $11.4 Billion Bet on Battery Independence

Ford isn’t content with being just a customer of battery makers. They’re building their own BlueOval network of battery plants, with a total investment of $11.4 billion. Here’s what’s coming:

- BlueOval City (Tennessee) – A 3,600-acre mega-campus opening in 2025. It will produce F-Series EVs and a new generation of batteries using SK On’s technology.

- BlueOval Battery Park (Michigan) – The LFP battery plant (with CATL tech) launching in 2026. It will supply batteries for Mach-Es, Lightnings, and future affordable EVs.

- BlueOval SK (Kentucky) – A joint venture with SK On to produce NCM batteries for Ford and Lincoln EVs.

Why this matters: By 2026, Ford aims to produce 600,000 EVs annually in North America—and 90% of those batteries will come from BlueOval facilities. This reduces reliance on third-party suppliers and gives Ford more control over costs, quality, and innovation.

Solid-State Batteries: The Next Frontier

While lithium-ion batteries dominate today, Ford is investing in solid-state batteries for the future. These promise 2–3x the energy density (meaning longer range), faster charging, and improved safety (no liquid electrolytes = less fire risk). Ford has partnered with Solid Power, a Colorado-based startup, to develop this tech. They’ve already built prototype batteries and plan to start testing in Ford vehicles by 2026.

What to watch: If solid-state batteries hit the market by 2030, Ford could offer EVs with 500+ miles of range and 10-minute charging. That’s a game-changer for long-distance travel.

Battery Performance and Real-World Ownership

How Ford Batteries Stack Up: Range, Charging, and Longevity

Let’s talk numbers. Here’s how Ford’s current batteries compare to rivals:

| Model | Battery Supplier | Battery Type | Capacity (kWh) | EPA Range (miles) | DC Fast Charging Speed |

|---|---|---|---|---|---|

| Mustang Mach-E (Extended Range) | SK On | NCM | 91 | 314 | 150 kW (10–80% in ~45 mins) |

| F-150 Lightning (Extended Range) | SK On | NCM | 131 | 320 | 150 kW (15–80% in ~41 mins) |

| E-Transit | LG Energy Solution | NCM | 68 | 126 | 115 kW (15–80% in ~34 mins) |

| Ford Explorer EV (2025, est.) | SK On | NCM | 100+ | 300+ | 200+ kW (10–80% in ~20 mins) |

Key takeaways:

- Ford’s NCM batteries are competitive with rivals like Tesla and Hyundai in range and charging speed.

- LFP batteries (coming in 2024–2025) will offer lower upfront costs and better longevity but slightly less range.

- Ford’s charging network (BlueOral) will include 10,000+ fast chargers by 2024, reducing “range anxiety.”

Ownership Tips: Maximizing Your Battery’s Lifespan

Want your Ford EV’s battery to last? Follow these tips:

- Avoid extreme temperatures: Park in a garage when possible. Heat degrades batteries faster.

- Don’t charge to 100% daily: For regular use, keep the battery at 80–90% to prolong lifespan.

- Use scheduled charging: Ford’s app lets you set charging to finish just before you leave—ideal for avoiding overcharging.

- Precondition the battery: Before a cold-weather drive, use the app to warm the battery. This improves range and charging speed.

The Bigger Picture: Sustainability and Ethics

Reducing Reliance on Cobalt and Nickel

Most EV batteries today rely on cobalt and nickel, which are mined in regions with human rights and environmental concerns (e.g., Congo for cobalt). Ford is tackling this in two ways:

- LFP batteries: By switching to LFP (which uses iron instead of nickel/cobalt), Ford eliminates these materials from its affordable EVs.

- Recycling: Ford’s partnership with Redwood Materials (a startup founded by Tesla’s ex-CTO) will recycle old batteries into new ones, reducing the need for mining.

The impact: By 2035, Ford aims to make 40% of its global battery supply “circular” (recycled or low-impact materials).

Localizing the Supply Chain

Ford’s BlueOval plants will source raw materials (lithium, graphite, etc.) from North America, reducing dependence on China. For example, the Michigan LFP plant will get lithium from a mine in Quebec, Canada.

Conclusion: The Power Behind Ford’s Electric Future

So, who makes the batteries for Ford electric cars? The answer is a mix of global giants (SK On, LG, CATL), cutting-edge startups (Solid Power), and Ford’s own bold investments (BlueOval). This hybrid approach—leveraging partners for today’s tech while building independence for tomorrow—is what makes Ford’s EV strategy unique.

For you, the driver, this means access to reliable, high-performance batteries today (like the SK On-powered Mach-E) and exciting innovations ahead (LFP, solid-state). Whether you’re drawn to Ford’s rugged F-150 Lightning or the sleek Mach-E, you can trust that the battery powering it is the result of years of collaboration and engineering.

And the best part? Ford’s not stopping here. With BlueOval, recycling partnerships, and a focus on sustainability, they’re not just keeping up with the EV race—they’re shaping its future. So next time you’re cruising in your Ford EV, remember: that battery under your feet is a testament to a century of automotive know-how and a bold leap into the electric era.

Frequently Asked Questions

Who makes the batteries for Ford electric cars?

Ford electric car batteries are primarily manufactured by SK Innovation, a South Korean battery supplier, through a joint venture called BlueOval SK. This partnership supplies lithium-ion batteries for models like the F-150 Lightning and Mustang Mach-E.

Are Ford electric car batteries made in the USA?

Yes, Ford is investing heavily in U.S.-based battery production through BlueOval SK. Facilities in Kentucky and Tennessee will manufacture batteries domestically starting in 2025, reducing reliance on overseas supply chains.

Which company supplies Ford with EV battery cells?

SK On, a subsidiary of SK Innovation, is Ford’s main supplier of EV battery cells. The two companies collaborate through BlueOval SK to produce batteries with high energy density and fast-charging capabilities.

Does Ford make its own electric car batteries?

While Ford doesn’t manufacture batteries alone, it co-owns BlueOval SK with SK On to produce batteries specifically for Ford and Lincoln EVs. This vertical integration ensures quality control and supply stability.

What type of batteries do Ford electric cars use?

Ford electric cars use nickel-cobalt-manganese (NCM) lithium-ion batteries, chosen for their balance of energy density, longevity, and thermal stability. Future models may adopt LFP (lithium iron phosphate) chemistry for cost efficiency.

Where are Ford EV batteries produced for current models?

Current Ford EV batteries are produced at SK On’s factory in Georgia, USA, and imported from South Korea. The upcoming BlueOval SK plants in Kentucky and Tennessee will localize production for North American models.