You Must Create A _______ Perimeter Or Buffer Zone Around The Work Area That Does Not Have Any Metal Objects. 1-Foot 10-Foot 5-Foot 3-Foot: Safety Guide

If you’ve ever struggled with interference while locating utilities, calibrating instruments, or simply keeping a jobsite safe, you already know that the environment around your work matters. As a safety trainer and field tech who’s set up hundreds of controlled work areas, I can tell you this: you must create a _______ perimeter or buffer zone around the work area that does not have any metal objects. 1-foot 10-foot 5-foot 3-foot. The correct choice is 10-foot. In this guide, I’ll break down why a 10-foot metal-free buffer is the gold standard, when it’s required, how to set it up, and the practical tips that save time, reduce false readings, and prevent near-misses on real jobsites.

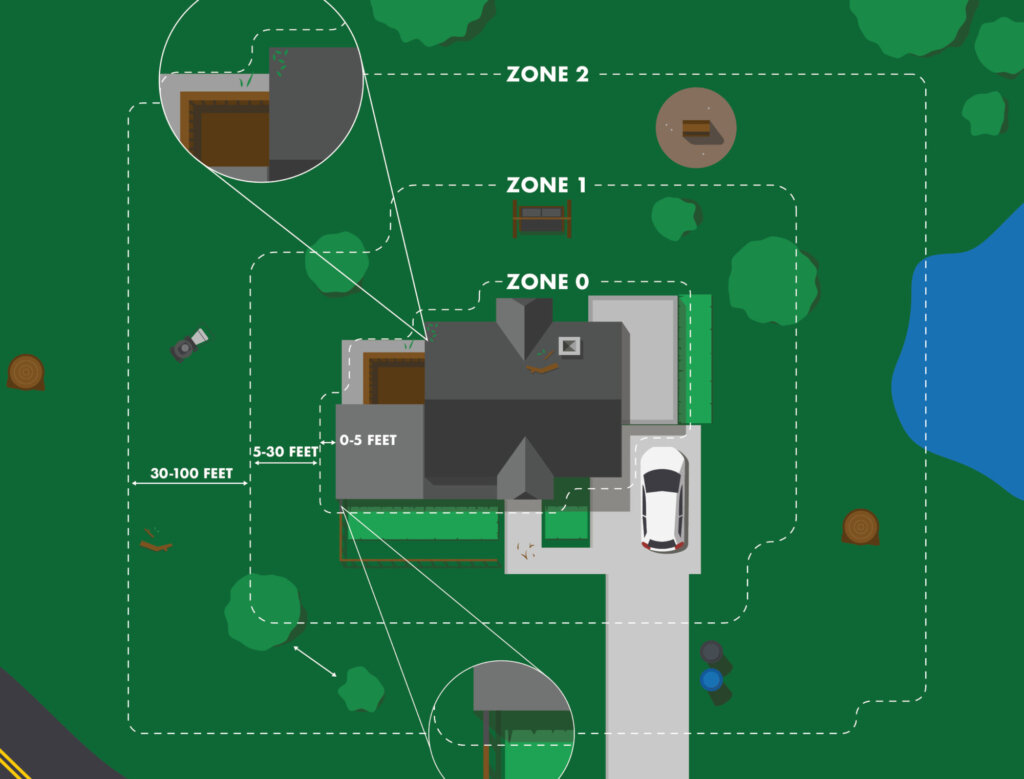

Source: readyforwildfire.org

Why A Metal-Free Buffer Zone Matters

Metal objects can distort electromagnetic fields, trigger false positives on metal detectors and magnetometers, compromise GPR data, and even increase risk when working near energized equipment. A clean perimeter is your first line of defense against bad data and unsafe conditions.

What’s at stake:

- Safety around electrical hazards. Metal can bridge gaps, attract arcing, or create unintended conductive paths.

- Data integrity for locating and scanning. Instruments like EM utility locators, magnetometers, and ferromagnetic detectors are highly sensitive to nearby metal.

- Workflow efficiency. False readings waste hours and lead to unnecessary excavation or missed targets.

- Regulatory and best-practice compliance. Industry guidance for utility locating and electromagnetic measurements supports establishing a clear, metal-free perimeter.

From field experience, the most common culprit is “hidden metal” we forget about: trucks parked too close, rebar-laced concrete, metal ladders, tape measures, or even steel-toe boots placed near the receive antenna. A deliberate buffer prevents these gotchas before they happen.

Source: aurora.municipal.codes

The Correct Answer: Create A 10-Foot Perimeter

Among the options 1-foot, 3-foot, 5-foot, and 10-foot, the correct and widely accepted best practice is a 10-foot metal-free perimeter around the work area.

Why 10 feet:

- Electromagnetic interference drops off with distance, and 10 feet provides a practical balance between safety, signal clarity, and site constraints.

- Common field instruments are sensitive enough that 1–5 feet often isn’t sufficient to eliminate coupling from fences, vehicles, or tools.

- Many utility locating and geophysical procedures adopt a similar standoff distance for grounding stakes, receivers, and calibration zones to minimize interference.

- It aligns with broader safety culture around energized or potentially hazardous work, where conservative standoff distances are preferred.

When you might need even more than 10 feet:

- High-sensitivity surveys using magnetometers or EM arrays in metal-dense environments.

- Work near large ferrous structures or heavily reinforced concrete.

- Calibration activities where precise baselines are required.

Source: readyforwildfire.org

How To Set Up A Metal-Free 10-Foot Buffer Zone

Follow this step-by-step process to create a reliable buffer around your work area.

- Identify the work center. Mark the primary instrument location, calibration area, or task center.

- Measure a 10-foot radius. Use a tape or a pre-marked rope. A paint mark or chalk circle helps keep everyone honest.

- Remove metal objects. Clear the zone of tools, rebar chairs, carts, ladders, shovels, metal signs, and debris. Don’t forget personal items like phones with magnetic mounts.

- Reposition vehicles and equipment. Move trucks, skid steers, compressors, and generators at least 10 feet away, preferably farther if possible.

- Check the ground. Reinforced slabs and metal covers can affect readings. If you must work on a slab, note the limitation and, if possible, shift your setup.

- Control access. Use cones, flags, or barricade tape to maintain the buffer. Brief the crew so nobody drifts into the zone with a wrench or tool belt.

- Re-verify during the job. Conditions change. Do a quick sweep each time you move or re-calibrate equipment.

- Document the setup. Take a photo and note the buffer in your job log for quality assurance.

Pro tip from the field: keep a “clean kit” bucket with plastic or composite tools, non-metallic stakes, and fiberglass measuring rods for use inside the buffer.

Source: readyforwildfire.org

Common Mistakes And How To Avoid Them

- Parking too close. A truck bumper or toolbox 6 feet away can skew your reading. Move it beyond the 10-foot line.

- Overlooking wearables. Steel-toe boots, metal watchbands, and smart devices can affect sensitive instruments when you lean in. Step back during measurements.

- Forgetting underground or embedded metal. Manhole rings, valve boxes, trench plates, and rebar change local fields. If present, expand the buffer and note the limitation in your report.

- Improper grounding. When using a transmitter and ground stake, maintain at least 10 feet from other metal to prevent signal coupling.

- Skipping crew briefings. If your team doesn’t know the buffer rules, tools will creep back in. A 60-second tailboard talk saves hours.

- Not adjusting for wind or workflow. Cones blow over. Stage weights or water-filled bases to keep the buffer visible.

Lessons learned: My biggest time sink used to be chasing ghost signals next to chain-link fences. Extending the buffer to 15–20 feet on the fence side and approaching targets from multiple headings virtually eliminated false hits.

Source: online.encodeplus.com

Tools, Materials, And A Quick Checklist

Helpful tools:

- Measuring tape or pre-marked 10-foot rope

- Cones, flags, or barricade tape

- Non-metallic stakes and fiberglass rods

- Plastic or composite hand tools

- Jobsite log or digital form for documentation

- Handheld EM or magnetometer with baseline check mode

10-foot buffer checklist:

- Defined center point established

- 10-foot radius measured and marked

- All metal objects removed from zone

- Vehicles/equipment repositioned

- Crew briefed on buffer rules

- Environmental limitations noted

- Photo taken and buffer documented

Source: www.networldsports.com

Real-World Scenarios And Case Studies

- Utility locating near a fence line. We were tracing a gas service parallel to a chain-link fence. The receiver spiked randomly. After pushing our buffer to 15 feet on the fence side and clearing metal tools, the trace stabilized, and the markout matched the as-builts within inches.

- GPR and magnetometer on a reinforced slab. A client insisted on scanning atop a heavy rebar mat. We documented the limitation, established a 10-foot clean zone for equipment calibration off the slab, and used cross-line passes to validate anomalies. The buffer preserved calibration integrity.

- Transmitter grounding in crowded alleyways. A ground stake too close to a steel dumpster created coupling, making the line look like it bent toward the dumpster. Moving the dumpster beyond 10 feet corrected the path instantly.

- Sensitive compass/IMU calibration for robotics. During a drone compass calibration, we discovered underground utilities were distorting readings. Relocating to a known metal-free 10-foot perimeter area solved the drift and prevented flyaway risks.

Key takeaway: The 10-foot rule is a simple control with outsized returns. It reduces noise, improves safety, and makes your data defensible.

Frequently Asked Questions Of You Must Create A _______ Perimeter Or Buffer Zone Around The Work Area That Does Not Have Any Metal Objects. 1-Foot 10-Foot 5-Foot 3-Foot

What is the correct buffer distance around the work area?

The correct answer is a 10-foot perimeter that is free of metal objects. This distance helps minimize electromagnetic interference and improves both safety and data quality.

Why isn’t 1-foot, 3-foot, or 5-foot enough?

At shorter distances, metal objects can still couple with signals or distort magnetic fields. Ten feet provides a more reliable standoff for common field instruments and safety practices.

Does the 10-foot rule apply to all tools and equipment?

Yes, as a baseline. Keep vehicles, metal tools, ladders, carts, and even personal items with metal outside the 10-foot zone. For highly sensitive instruments, increase the distance if needed.

What if I’m working on reinforced concrete?

Rebar can affect readings. If you must work on it, document the limitation, perform calibrations in a nearby metal-free area, and consider increasing the buffer or using cross-check methods.

How do I maintain the buffer on a busy jobsite?

Mark the 10-foot radius, brief the crew, use cones or barrier tape, and assign someone to periodically verify the area stays clear. Visual controls and quick reminders are key.

Are there standards that support this practice?

Industry best practices in utility locating, electromagnetic surveying, and safety management endorse establishing a metal-free perimeter to control interference and hazards. Many procedures specify or imply a minimum 10-foot standoff.

Wrap-Up And Next Steps

A 10-foot metal-free perimeter is a small investment that pays off in safer jobsites, cleaner data, and fewer headaches. Establish the zone, enforce it, and document it. Start with 10 feet, expand when conditions demand, and make the buffer part of your standard operating procedure. Try it on your next locate, scan, or calibration, and watch your results stabilize.

Ready to level up your field practices? Subscribe for more practical guides, download our free buffer checklist, or drop a comment with your toughest interference challenge—we’ll help you solve it.