Toyota Electric Car Manufacturing Future Plans Revealed

Featured image for toyota electric car manufacturing

Image source: electriccarspedia.com

Toyota has unveiled an aggressive roadmap to dominate the electric vehicle market, targeting 3.5 million EV sales annually by 2030. The automaker plans to invest over $70 billion in electrification, including new battery plants and fully electric models across all major vehicle segments. This strategic shift underscores Toyota’s commitment to phasing out combustion engines and leading the future of sustainable mobility.

Key Takeaways

- Toyota plans 10 new EV models by 2026 to expand its electric lineup globally.

- Battery innovation is a top priority, focusing on solid-state and high-density technologies.

- $13.6 billion committed to EV development through 2030 for manufacturing and R&D.

- Local production hubs will reduce costs and improve supply chain efficiency.

- Hybrid transition remains key while scaling full electric vehicle output.

- Partnerships with tech firms accelerate progress in software and autonomous integration.

- Sustainability drives manufacturing goals, aiming for carbon-neutral plants by 2035.

📑 Table of Contents

- Toyota Electric Car Manufacturing Future Plans Revealed

- Toyota’s Shift Toward Full Electrification

- Advanced Battery Technology and Production

- New EV Models and Platform Development

- Manufacturing Innovations and Sustainability

- Challenges and How Toyota Is Addressing Them

- Data Table: Toyota’s Electric Car Manufacturing Roadmap (2024–2030)

- Conclusion

Toyota Electric Car Manufacturing Future Plans Revealed

Imagine walking into a car dealership in 2030 and finding that every Toyota on the lot runs on electricity. No more gas pumps, no more oil changes—just quiet, clean, and efficient rides powered by advanced batteries. That future isn’t science fiction. It’s the vision Toyota is actively building today. For decades, Toyota has been a household name synonymous with reliability, innovation, and hybrid technology. From the iconic Prius to the rugged RAV4 Hybrid, the Japanese automaker has long been a pioneer in sustainable mobility. But as the world shifts toward full electrification, Toyota is stepping up its game with bold plans to transform its electric car manufacturing.

You might be wondering: “Wait, isn’t Toyota a bit late to the electric party?” It’s a fair question. While Tesla, Hyundai, and even Ford have rolled out multiple fully electric models, Toyota has been more cautious, focusing heavily on hybrids and hydrogen fuel cells. But that hesitation isn’t due to a lack of vision—it’s part of a carefully calculated strategy. Toyota believes in a diversified approach to decarbonization, one that includes hybrids, plug-in hybrids, hydrogen vehicles, and yes, fully electric cars. Now, with new leadership, massive investments, and a clear roadmap, Toyota is finally accelerating its electric ambitions. In this post, we’ll dive deep into Toyota’s electric car manufacturing future plans, what they mean for drivers, and how the company plans to compete in an increasingly electric world.

Toyota’s Shift Toward Full Electrification

Toyota’s journey into electric vehicles (EVs) hasn’t been a straight line. For years, the company championed hybrid technology as the most practical path to reducing emissions, especially in markets where charging infrastructure was limited. The Prius, launched in 1997, became a global symbol of eco-friendly driving. But as battery technology improved and governments around the world set aggressive carbon-neutral goals, the demand for fully electric cars surged. Toyota realized it needed to pivot—fast.

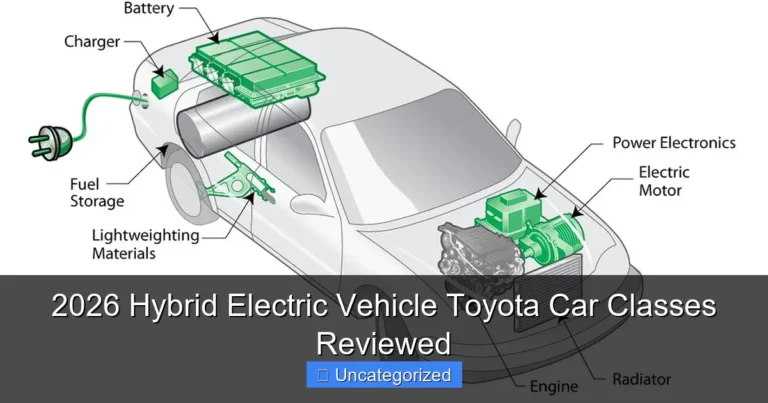

Visual guide about toyota electric car manufacturing

Image source: meanmetalmotors.com

Why the Change in Strategy?

The turning point came in 2021, when Toyota announced a $70 billion investment in electrification by 2030. That’s not just a number—it’s a signal that the company is serious about catching up and competing with EV leaders. Part of the reason for the delay was Toyota’s belief that not all regions were ready for full EVs. In rural areas or developing countries, charging stations are still scarce, and hybrids offered a more practical solution. But with global EV sales expected to reach 30 million units annually by 2030, Toyota can no longer afford to sit on the sidelines.

Another factor? Consumer expectations. People want electric cars that are not only eco-friendly but also fun to drive, packed with tech, and affordable. Toyota’s early EV efforts, like the bZ4X SUV, showed promise but faced setbacks—like a recall due to wheel hub issues. These early hiccups taught Toyota valuable lessons about quality control and the importance of getting EVs right the first time.

The New Leadership Driving Change

In 2023, Toyota appointed a new CEO, Koji Sato, who has made electrification a top priority. Unlike his predecessors, Sato has openly acknowledged the need for faster EV development and has pushed for a more agile, innovation-driven culture. Under his leadership, Toyota has streamlined its EV development process, created dedicated EV teams, and partnered with tech companies to improve battery performance and software integration.

One of Sato’s key messages has been: “We’re not just building electric cars—we’re rethinking how we manufacture them.” This mindset shift is crucial. It’s not enough to slap a battery into a traditional car. Toyota is redesigning its entire production philosophy to support scalable, efficient, and sustainable EV manufacturing.

Advanced Battery Technology and Production

At the heart of any electric car is the battery—and Toyota knows it. The company has been investing heavily in next-generation battery technology to improve range, reduce costs, and speed up charging times. Their goal? To deliver EVs that are not only competitive but superior in key areas like longevity and safety.

Solid-State Batteries: The Game Changer

Toyota is betting big on solid-state batteries. Unlike traditional lithium-ion batteries, which use liquid electrolytes, solid-state batteries use a solid material to transfer ions. This design offers several advantages: higher energy density, faster charging, longer lifespan, and improved safety (less risk of fire). Toyota has been researching solid-state tech for over a decade and plans to launch its first solid-state battery-powered EV by 2027.

Imagine charging your car in just 10 minutes and getting over 500 miles of range. That’s the promise of solid-state batteries. While other automakers are also working on this tech, Toyota claims it has a head start. The company has filed over 1,000 patents related to solid-state batteries—more than any other automaker. They’re also building a dedicated production line in Japan to scale up manufacturing once the technology is ready.

Battery Manufacturing Expansion

To support its EV ambitions, Toyota is expanding its battery production capacity. The company has partnered with Panasonic to build a new battery plant in North Carolina, set to open in 2025. This facility will produce lithium-ion batteries for Toyota’s upcoming EVs and is expected to create over 1,700 jobs. Toyota also plans to build additional battery plants in Japan and Europe, ensuring a stable supply chain and reducing reliance on external suppliers.

One smart move? Toyota is designing its batteries to be modular. This means they can be easily swapped or upgraded, extending the life of the vehicle and reducing waste. It’s a forward-thinking approach that aligns with the principles of a circular economy.

Sustainability in Battery Production

Toyota isn’t just focused on performance—it’s also committed to sustainability. The company is working to reduce the carbon footprint of its battery production by using renewable energy in its factories and sourcing materials responsibly. For example, Toyota is exploring ways to recycle old batteries and recover valuable materials like lithium, cobalt, and nickel. This not only cuts costs but also reduces environmental impact.

They’re also investing in alternative battery chemistries, like lithium-iron-phosphate (LFP), which are cheaper and more abundant than nickel-rich batteries. While LFP batteries have slightly lower energy density, they’re safer and last longer—perfect for city driving and fleet vehicles.

New EV Models and Platform Development

Toyota’s electric future isn’t just about batteries—it’s about building a whole new lineup of vehicles designed from the ground up as EVs. The company is developing a dedicated electric platform called the “e-TNGA” (Electric Toyota New Global Architecture), which will underpin most of its future electric models.

The bZ Series: Toyota’s Electric Lineup

Toyota’s electric vehicles will fall under the “bZ” (Beyond Zero) brand, signaling a commitment to carbon neutrality. The bZ4X, launched in 2022, was the first model in this series. It’s a compact SUV with up to 250 miles of range, all-wheel drive, and a spacious interior. While it received mixed reviews initially, Toyota has used customer feedback to improve the design and software for future models.

Coming soon? The bZ3, a sleek electric sedan developed in partnership with BYD, a Chinese EV giant. This car is designed specifically for the Chinese market but may expand globally. It features a minimalist interior, advanced driver-assistance systems, and a range of over 370 miles. Toyota is also working on a larger bZ5 SUV and a compact bZ2 crossover, expected to launch by 2026.

Performance and Luxury EVs

Toyota isn’t just targeting the mass market. The company is also developing high-performance and luxury electric models under its Lexus brand. The Lexus RZ 450e, for example, is a premium electric SUV with a sporty design, dual-motor all-wheel drive, and a range of over 220 miles. It’s a sign that Toyota wants to compete with brands like BMW and Mercedes in the luxury EV space.

Even more exciting? Rumors of an electric Supra. While Toyota hasn’t confirmed it yet, insiders suggest the iconic sports car could go fully electric by 2028. Imagine a zero-emission Supra with instant torque and a futuristic design—now that’s something to look forward to.

Affordability and Accessibility

One of Toyota’s biggest goals is to make electric cars affordable for everyone. The company plans to offer EVs at various price points, from budget-friendly compact cars to premium SUVs. By 2030, Toyota aims to sell 3.5 million electric vehicles annually—about one-third of its total global sales. To hit that target, they’ll need to keep prices competitive.

How? By leveraging economies of scale, improving manufacturing efficiency, and using cheaper battery chemistries. Toyota also plans to offer flexible ownership models, like battery leasing and subscription services, to lower the upfront cost for buyers.

Manufacturing Innovations and Sustainability

Building electric cars isn’t just about the vehicles—it’s about how they’re made. Toyota is reimagining its manufacturing processes to be more efficient, flexible, and sustainable. The company’s “Toyota Production System” (TPS), known for its lean manufacturing principles, is being adapted for the EV era.

Flexible EV Production Lines

Traditional car factories are built for specific models, making it hard to switch production quickly. Toyota is changing that by creating flexible assembly lines that can produce multiple EV models on the same line. This means they can respond faster to market demand and reduce downtime.

For example, Toyota’s plant in Kentucky is being retooled to produce both hybrid and electric versions of the RAV4. This kind of flexibility is crucial as consumer preferences shift and new models are introduced.

Green Manufacturing Practices

Toyota is committed to making its factories carbon-neutral by 2035. That means using renewable energy, reducing waste, and improving energy efficiency. At its plant in Tsutsumi, Japan—where the Prius was first built—Toyota has installed solar panels and uses recycled water in its processes. The company is also exploring hydrogen-powered forklifts and other clean technologies for its factories.

Another innovation? “Digital twins”—virtual replicas of physical factories that allow engineers to simulate and optimize production before making real-world changes. This reduces errors, saves time, and cuts costs.

Localizing Production

To reduce shipping emissions and support local economies, Toyota is localizing EV production. Instead of building all EVs in Japan and shipping them worldwide, the company is setting up regional manufacturing hubs. The North Carolina battery plant is a prime example. By 2030, Toyota plans to produce EVs in the U.S., Europe, China, and Southeast Asia, tailored to local markets.

This approach also helps Toyota navigate trade policies and tariffs, making its EVs more competitive in different regions.

Challenges and How Toyota Is Addressing Them

Of course, Toyota’s electric future isn’t without challenges. From supply chain issues to consumer skepticism, the road ahead is full of obstacles. But Toyota is tackling them head-on with smart strategies and long-term planning.

Supply Chain and Material Shortages

One of the biggest hurdles in EV manufacturing is securing enough raw materials—especially lithium, cobalt, and nickel. These minerals are essential for batteries, but mining them can be environmentally damaging and ethically questionable. Toyota is addressing this by diversifying its supply chain, investing in recycling, and developing alternative battery chemistries that use fewer rare materials.

They’re also partnering with mining companies to ensure responsible sourcing and transparency. For example, Toyota has joined the Global Battery Alliance, a coalition working to create a sustainable battery value chain.

Charging Infrastructure and Consumer Adoption

Even the best electric car is useless without a place to charge it. Toyota recognizes this and is working with governments, utilities, and private companies to expand charging networks. In the U.S., Toyota has partnered with EVgo to offer free charging for new bZ4X owners. In Europe, they’re supporting the rollout of fast-charging stations along major highways.

But infrastructure isn’t the only barrier. Many consumers are still hesitant to switch to EVs due to concerns about range, cost, and reliability. Toyota is addressing these concerns through education, test drives, and strong warranties. The bZ4X, for example, comes with a 10-year battery warranty—longer than most competitors.

Competition from EV Leaders

Toyota faces stiff competition from Tesla, which dominates the EV market with over 1.8 million vehicles sold in 2023. Other automakers like Hyundai, Kia, and Ford are also gaining ground with stylish, high-performing EVs. To compete, Toyota is focusing on what it does best: reliability, quality, and customer service.

While Tesla leads in software and innovation, Toyota excels in durability and resale value. The company is betting that many buyers will choose a Toyota EV not for flashy tech, but for peace of mind and long-term value.

Data Table: Toyota’s Electric Car Manufacturing Roadmap (2024–2030)

| Year | Key Milestone | Details |

|---|---|---|

| 2024 | bZ3 Sedan Launch | Electric sedan for Chinese market, developed with BYD |

| 2025 | North Carolina Battery Plant Opens | Produces lithium-ion batteries for U.S. EVs |

| 2026 | bZ5 SUV and bZ2 Crossover Launch | New models based on e-TNGA platform |

| 2027 | First Solid-State Battery EV | Expected range: 500+ miles, 10-minute charging |

| 2028 | Electric Supra (Rumored) | High-performance sports car, fully electric |

| 2030 | 3.5 Million EVs Annually | One-third of global sales; carbon-neutral factories |

Conclusion

Toyota’s electric car manufacturing future is no longer a distant dream—it’s a concrete plan backed by billions in investment, cutting-edge technology, and a clear vision. While the company may have been slower to embrace full electrification than some rivals, its methodical approach is starting to pay off. With advanced solid-state batteries, a growing lineup of bZ models, and a commitment to sustainable manufacturing, Toyota is positioning itself as a serious player in the EV market.

What does this mean for you? If you’ve been waiting for a reliable, well-built electric car from a brand you trust, your time may be coming soon. Toyota’s EVs won’t just be about going green—they’ll be about delivering the quality, durability, and value that the brand is known for. And with plans to make electric cars more affordable and accessible, Toyota is helping to bring the benefits of electrification to a wider audience.

The road ahead is electric, and Toyota is finally in the fast lane. Whether you’re a longtime fan or a skeptical shopper, it’s worth keeping an eye on what this automotive giant has in store. The future of driving is changing—and Toyota is helping to shape it.

Frequently Asked Questions

What is Toyota’s plan for electric car manufacturing in the coming years?

Toyota has announced ambitious plans to expand its electric car manufacturing, aiming to launch 30 new battery electric vehicles (BEVs) globally by 2030. The company plans to invest $70 billion in electrification efforts, including dedicated EV production lines and battery development.

How does Toyota’s electric car manufacturing compare to other automakers?

While Toyota was initially slower to adopt full electric vehicle production compared to Tesla or GM, it is now accelerating its EV manufacturing with new platforms and factories. The company emphasizes a balanced approach, investing in hybrids, plug-ins, and fuel cells alongside battery electric cars.

Where will Toyota build its new electric cars?

Toyota is expanding electric car manufacturing in key markets, including the U.S., Japan, and Europe. In the U.S., the company is investing in its North Carolina battery plant and upgrading existing facilities to support future EV production.

What role will solid-state batteries play in Toyota’s electric car manufacturing?

Toyota is a leader in solid-state battery research and plans to integrate this technology into its electric car manufacturing by the mid-2020s. These batteries promise faster charging, longer range, and improved safety, giving Toyota a competitive edge in the EV market.

Will Toyota phase out gasoline cars in favor of electric car manufacturing?

Toyota does not plan to completely phase out gasoline vehicles but aims for electrified models—including hybrids and BEVs—to make up 100% of its global sales by 2035. The company supports a gradual transition to meet diverse customer needs and infrastructure readiness.

How will Toyota ensure sustainability in its electric car manufacturing process?

Toyota is focusing on sustainable electric car manufacturing by using recycled materials, reducing factory emissions, and sourcing renewable energy. The company also emphasizes a circular economy approach, including battery recycling and reuse programs.